What Is Bend Deduction?

Bend deduction is a critical aspect of press brake bending.

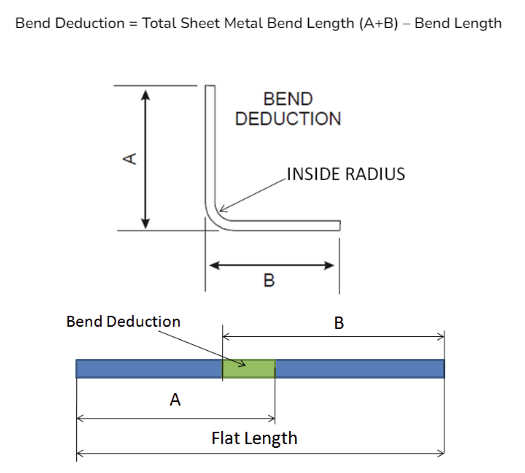

The size of the workpiece, as depicted in a graphic design drawing, is different from its size in the bent state.

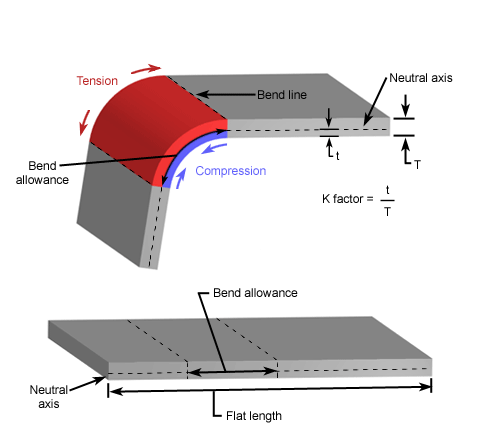

During the press brake bending process, the tension stretches the outer material, causing it to elongate, while the inner material is compressed.

The neutral axis remains unaffected by pressure or tension, hence, its length remains unchanged.

As a result of these changes, the size of the workpiece after bending is different from the size of the flat pattern.

To correct the bending point and flange length, it's necessary to calculate the bend deduction, which represents the amount to be subtracted from the workpiece size after bending.

In simpler terms, Bend Deduction (BD) refers to the extent to which the sheet is stretched after the tension applied during bending is released."

Thus, the value of bend deduction is equal to the difference between the total flange length and the total flat length.

How to Calculate Bend Deduction?

The parameters required for calculating bend deduction are the material thickness, bending angle, internal radius, and K factor.

The K factor, which is the ratio of the distance between the neutral line and the material edge to the material thickness, is determined by the material thickness and bending method.

The formula for the K factor is:

K = t/T

Where t is the distance from the neutral line to the material edge and T is the material thickness.

The range for the K factor is generally between 0.3 and 0.5.

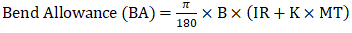

We have introduced the calculation formula for the bend allowance:

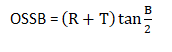

If we know the bend allowance (BA) and the outside setback(OSSB), we can quickly calculate the bend deduction.

BD=2 · OSSB - BA

The calculation formula of outside setback(OSSB) is:

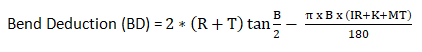

When we know these parameters, the bend deduction calculation formula can also be:

Where K represents the K factor, R and IR both represent the inner radius, T represents material thickness, B represents the bending angle, and MT also represents plate thickness.

Conclusion

The calculation of bend deduction is crucial in the preparation of sheet metal bending. Accurate calculation results are necessary to produce precise bending workpieces.

We are a professional manufacturer of sheet metal processing machines, with extensive experience in the industry and cutting-edge technology.

For more information on bending and our products, please feel free to contact us or visit our website for press brake information.