I. Einleitung

A Abkantpresse ist ein gängiges industrielles Produktionswerkzeug, das zum Biegen einer Vielzahl von Materialien wie Stahl-, Aluminium- und Kupferplatten verwendet wird.

Das Wissen und die Technik der Abkantpresse sind ihre Grundlagen, die Ihnen bei der Nutzung in der Fertigung helfen.

Mein Text zeigt Ihnen diese Informationen, einschließlich des K-Faktors, der Biegezugabe und des Biegeabzugs.

Der K-Faktor, der auch als Biegeradiusfaktor bezeichnet wird, berücksichtigt die Tendenz des Materials, sich beim Biegen an der Außenfläche zu dehnen und an der Innenfläche zu stauchen.

Die korrekte Berechnung des K-Faktors ist wichtig für die Bestimmung der neutralen Achsenposition und die Minimierung möglicher Defekte wie Rissbildung oder Faltenbildung.

Die Biegezugabe bezieht sich auf das zusätzliche Material, das erforderlich ist, um den Biegeradius auszugleichen und eine übermäßige Dehnung oder Stauchung des Materials zu verhindern.

Die genaue Berechnung der Biegezugabe ist entscheidend, um sicherzustellen, dass die endgültigen Abmessungen des Teils mit den Konstruktionsspezifikationen übereinstimmen.

Der Biegeabzug hingegen kompensiert den Rückfederungseffekt des Materials, bei dem das gebogene Teil dazu neigt, sich nach Wegnahme der Biegekraft teilweise wieder zurückzubiegen.

Die Berücksichtigung des Biegeabzugs ist wichtig, um den gewünschten Biegewinkel zu erreichen und die Maßgenauigkeit zu erhalten.

Wenn Sie diese wesentlichen Faktoren verstehen und richtig anwenden, können Sie ihre Biegeprozesse optimieren, den Materialabfall minimieren und durchgängig qualitativ hochwertige Biegeteile herstellen, die den strengsten Anforderungen genügen.

II. Was ist der K-Faktor?

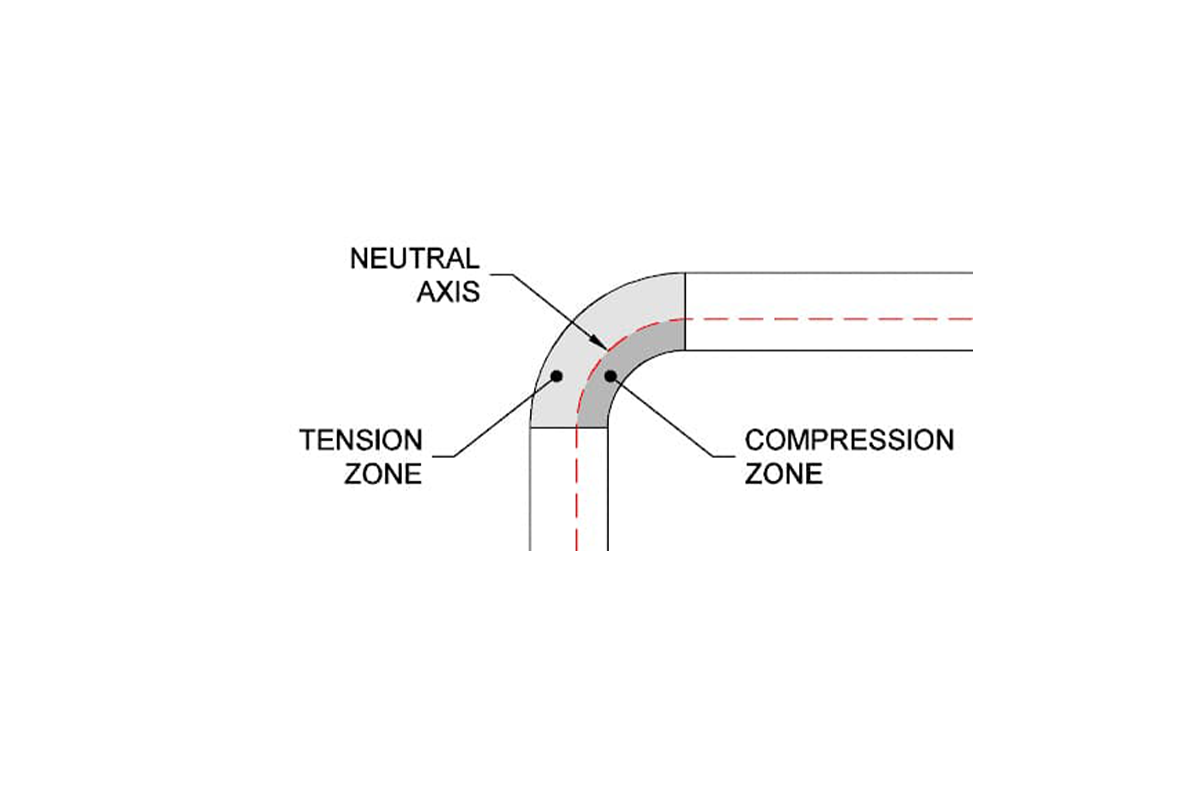

Zunächst müssen wir die neutrale Achse verstehen. Wenn ein Blech gebogen wird, wird die untere Fläche zusammengedrückt und die obere Fläche gedehnt.

Die neutrale Achse befindet sich im Inneren des Metalls, wo es weder gestaucht noch gedehnt wird, so dass es eine konstante Länge behält.

Bei flachen Blechen liegt die neutrale Achse gleichmäßig auf der Hälfte der Blechdicke, sie verschiebt sich jedoch beim Biegen.

Die Positionsveränderung der neutralen Achse wird durch verschiedene Faktoren wie Materialeigenschaften, Dicke, Biegewinkel, Innenradius und Biegeverfahren des Blechs bestimmt.

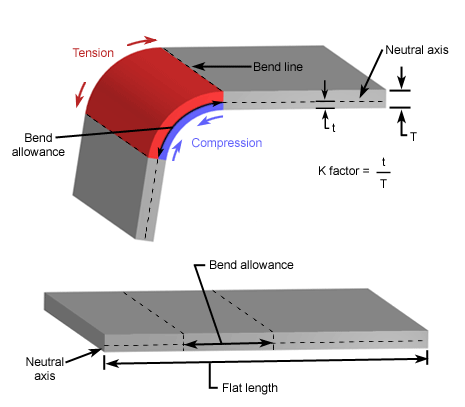

Mathematisch gesehen ist der K-Faktor das Verhältnis zwischen der Position der neutralen Achse (t) und der Plattendicke (T).

Dabei ist t der Abstand von der Innenfläche zur neutralen Achse und T die Metalldicke (Abbildung 1).

Der K-Faktor wird durch die physikalischen Eigenschaften des Materials, das Biegeverfahren, den Biegewinkel und andere Faktoren bestimmt.

Materialeigenschaften: Er liegt typischerweise zwischen 0,30 und 0,50. Im Allgemeinen liegt der K-Faktor von Weichkupfer oder weichen Kupferwerkstoffen bei 0,35, der K-Faktor von Werkstoffen wie halbhartem Kupfer oder Messing, Baustahl und Aluminium bei 0,41 und der K-Faktor von Werkstoffen wie Bronze, Hartkupfer, kaltgewalztem Stahl und Federstahl bei 0,45.

Biegeradius: je kleiner der Biegeradius, desto größer der K-Faktor.

Dicke des MaterialsJe größer die Materialstärke, desto größer der K-Faktor.

Die Streckgrenze des MaterialsJe höher die Streckgrenze, desto kleiner der K-Faktor.

Elastizitätsmodul (auch bekannt als Elastizitätsmodul)Je größer die Materialstärke, desto größer der K-Faktor.

Bei der Herstellung von Präzisionsblechen ist der K-Faktor ein entscheidender Faktor. Der K-Faktor wird zur Berechnung des flachen Biegemusters verwendet, das in direktem Zusammenhang mit der Länge des beim Biegen gestreckten Blechs steht.

Er ist der grundlegende Wert für die Bestimmung der Biegezugabe und des Biegeabzugs.

Da das Verhältnis zwischen dem Abstand zur neutralen Achse und der Blechdicke die Position der neutralen Achse im Blech bestimmt, hilft die Kenntnis des K-Faktors bei der Bestimmung der Position der neutralen Achse nach dem Biegen.

Sie können den K-Faktor auch anhand der nachstehenden Tabelle ermitteln:

Sie können auch die online & kostenlos K-Faktor-Rechner für perfektes Biegen von Blechen

III. Was ist die Biegezulage?

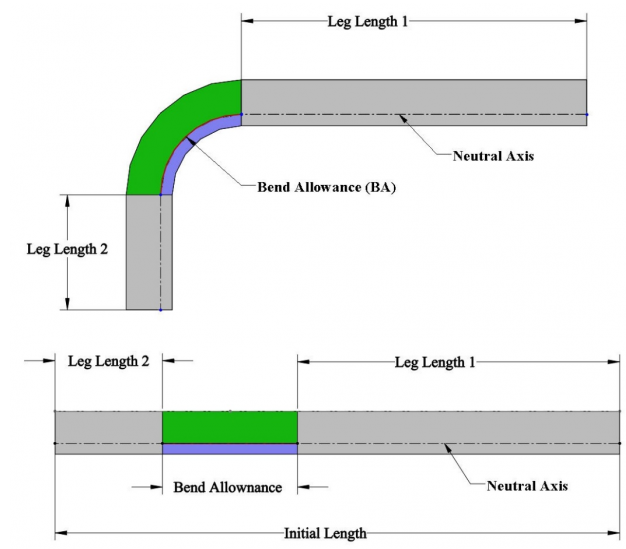

Die Biegezugabe (BA) ist die Bogenlänge der Biegung, die entlang der neutralen Achse des Blechs gemessen wird, da sich die Länge der neutralen Achse nach dem Biegen nicht ändert.

Sobald die Biegezugabe berechnet ist, sollte sie zur flachen Länge addiert werden, um die erforderliche Blechlänge zu bestimmen, die zum Formen des gewünschten Werkstücks benötigt wird.

Dies ist in der folgenden Abbildung dargestellt:

Die folgende Formel wird zur Berechnung der flachen Länge verwendet:

Blechplattenlänge=Beinlänge 1 +BA + Beinlänge 2

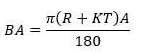

Formel zur Berechnung der Biegezulage:

Wo:

A - Biegewinkel

R - Innenradius

K - K-Faktor

T - Materialstärke

IV. Was ist der Beugeabzug?

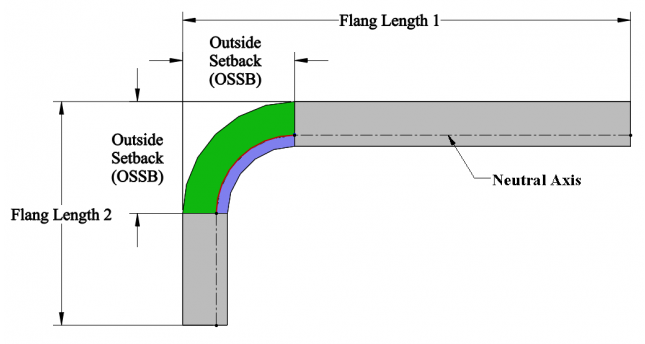

Nach dem Biegen ist die Flanschlänge (d. h. die Gesamtlänge) größer als die Länge des flachen Blechmusters.

Der Biegeabzug ist die Länge des Materials, die wir von der Gesamtlänge der Platte abziehen müssen, um das richtige flache Muster zu erhalten.

Gemäß der obigen Abbildung ist der Biegeabzug die Differenz zwischen der Biegezugabe und dem doppelten Außenabschlag.

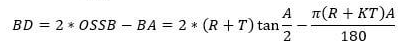

Formel für die Berechnung des Biegeabzugs:

Wo:

OSSB - Der Außenrücksprung (die Länge des Teils, die über den Biegewinkel hinausgeht).

R - Biegeradius

K - K-Faktor (bestimmt durch Materialeigenschaften und Dicke)

T - Materialstärke

A - Gewünschter Biegewinkel in Grad

Nehmen wir an, wir wollen ein 2 mm dickes Edelstahlblech zu einem 90°-Winkel mit einem inneren Biegeradius von 3 mm biegen. Der K-Faktor für dieses Material ist bekanntlich 0,44. Berechnen wir die Biegeabzugskraft Schritt für Schritt:

1. Berechnen Sie die Biegezulage (BA):

BA = π * (R + K * T) * (A / 180)

Dabei ist R der innere Biegeradius, K ist der K-Faktor, T ist die Blechdicke und A ist der Biegewinkel.

Einstecken der Werte:

BA = π * (3 + 0,44 * 2) * (90 / 180) = 4,39 mm

2. Berechnen Sie den Außenabstand (OSSB):

OSSB = R + T = 3 + 2 = 5 mm

3. Berechnen Sie den Biegeabzug (BD):

BD = 2 * OSSB - BA

Einstecken der Werte:

BD = 2 * 5 - 4,39 = 5,61 mm

Um eine 90°-Biegung mit einem inneren Biegeradius von 3 mm an diesem 2 mm dicken Edelstahlblech zu erreichen, müssen wir daher den Biegeabzug während des Biegevorgangs auf 5,61 mm einstellen.

Das bedeutet, dass wir das Blech um 5,61 mm überbiegen müssen, um die Rückfederung nach dem Biegen zu kompensieren und letztendlich den gewünschten 90°-Biegewinkel zu erreichen.

Die Berechnung des Biegeabzugs kann helfen, die Abmessungen des Teils vor dem Biegen zu bestimmen, was eine bessere Produktionsplanung und weniger Materialabfall ermöglicht.

V. Schlussfolgerung

Durch eine eingehende Untersuchung des K-Faktors, der Biegezugabe und des Biegeabzugs können wir die Rolle, die diese Schlüsselparameter im Biegeprozess spielen, besser verstehen.

Der K-Faktor bestimmt den Grad der Materialdehnung während des Biegens, die Biegezugabe definiert die tatsächlichen Abmessungen des Werkstücks nach dem Biegen, und der Biegeabzug hilft bei der Berechnung der Abmessungen des Werkstücks vor dem Biegen.

Die genaue Berechnung dieser Parameter ist entscheidend, um eine präzise Biegung zu erreichen und den Materialabfall zu reduzieren.

Der K-Faktor, die Biegezugabe und der Biegeabzug müssen jedoch durch wiederholte Versuche in der realen Produktion ermittelt werden, und theoretische Berechnungen können nur als erste Referenz verwendet werden.

Wenn Sie auf der Suche nach einem professionellen Abkantpressenhersteller sind, empfehle ich Ihnen ADH Machine Tool.

Als Branchenführer mit über 40 Jahren Erfahrung bietet ADH seinen Kunden durch seine außergewöhnliche Produktleistung und seinen hochwertigen Kundendienst umfassende Biegelösungen.

Sie können Durchsuchen Sie die Produktseite meines Unternehmens um sich über die neuesten Produktaktualisierungen und technischen Spezifikationen zu informieren, und ich bin sicher, dass Sie eine Abkantpresse finden werden, die Ihren Anforderungen entspricht.