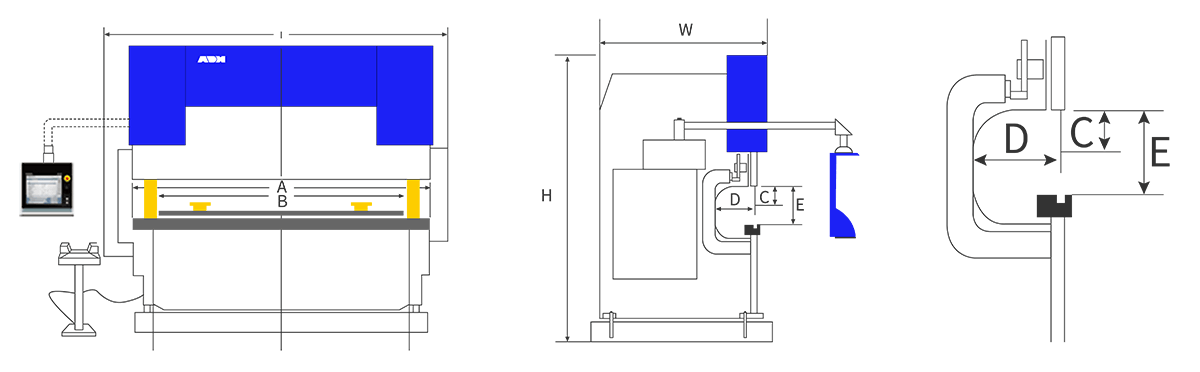

| Modell | Biegekraft | Biegen Länge (A) | Öltank | Vorauseilende Geschwindigkeit | Widder-Geschwindigkeit | Rücklaufgeschwindigkeit | Hub der X-Achse | X-Achse Geschwindigkeit | Hub der R-Achse | R-Achse Geschwindigkeit | Säulenabstand (B) | Kehlentiefe (D) | Schlaganfall (C) | Tageslicht (E) | Schritt/Servomotor | Gewicht | Abmessungen |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Einheit | KN | mm | L | mm/S | mm/S | mm/S | mm | mm/s | mm | mm/s | mm | mm | mm | mm | KW | Ton | L×B×H mm |

| 50T/1300 | 500 | 1300 | 170 | 160 | 13 | 160 | 500 | 350 | 200 | 200 | 1120 | 250 | 150 | 460 | 5.5/6 | 4 | 1800*1500*2300 |

| 50T/2000 | 500 | 2000 | 170 | 160 | 13 | 160 | 500 | 350 | 200 | 200 | 1600 | 250 | 150 | 460 | 5.5/6 | 4.3 | 2600*1500*2300 |

| 70T/1600 | 700 | 1600 | 170 | 220 | 13 | 160 | 500 | 350 | 200 | 200 | 1300 | 300 | 150 | 460 | 5.5/6 | 5.1 | 1800*1600*2500 |

| 70T/2500 | 700 | 2500 | 170 | 220 | 13 | 160 | 500 | 350 | 200 | 200 | 2050 | 300 | 150 | 460 | 5.5/6 | 5.6 | 3100*1600*2500 |

| 70T/3200 | 700 | 3200 | 170 | 220 | 13 | 160 | 500 | 350 | 200 | 200 | 2700 | 300 | 150 | 460 | 5.5/6 | 6.6 | 3700*1600*2500 |

| 80T/2500 | 800 | 2500 | 170 | 220 | 12 | 145 | 500 | 350 | 200 | 200 | 2050 | 300 | 150 | 460 | 7.5/8.7 | 6 | 3100*1600*2600 |

| 110T/2500 | 1100 | 2500 | 170 | 220 | 12 | 160 | 500 | 350 | 200 | 200 | 2050 | 400 | 200 | 480 | 11/10.8 | 7 | 3100*1800*2600 |

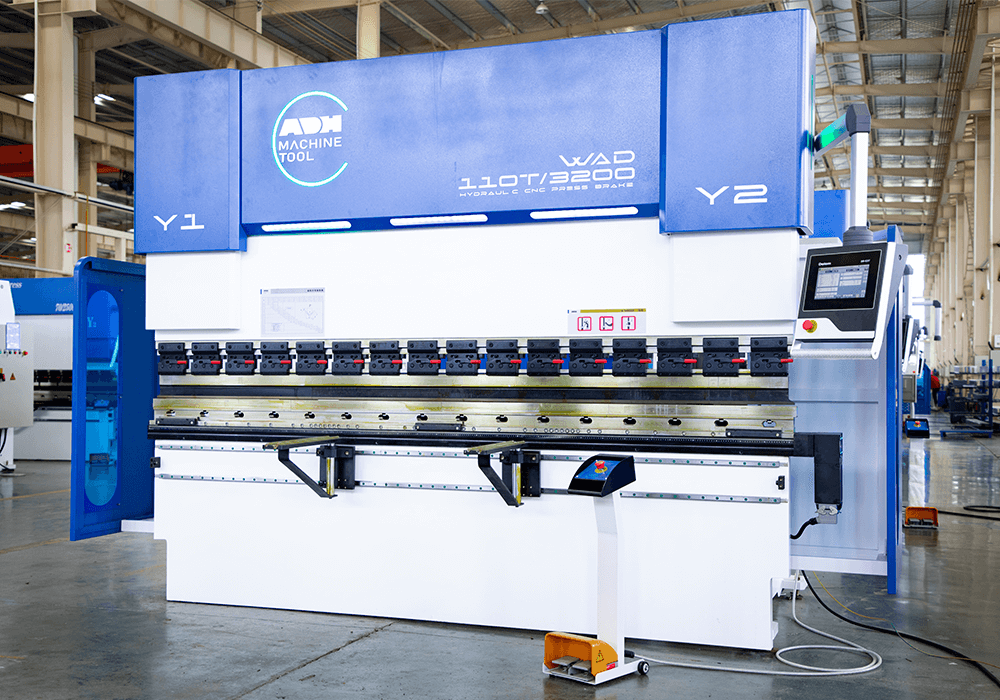

| 110T/3200 | 1100 | 3200 | 170 | 220 | 12 | 160 | 500 | 350 | 200 | 200 | 2700 | 400 | 200 | 480 | 11/10.8 | 7.6 | 3800*1800*2600 |

| 110T/4000 | 1100 | 4000 | 170 | 220 | 12 | 160 | 500 | 350 | 200 | 200 | 3100 | 400 | 200 | 480 | 11/10.8 | 8.8 | 4600*1800*2600 |

| 110T/4100 | 1100 | 4100 | 170 | 220 | 12 | 160 | 500 | 350 | 200 | 200 | 3600 | 400 | 200 | 480 | 11/10.8 | 9 | 4700*1800*2700 |

| 135T/3200 | 1350 | 3200 | 170 | 220 | 10 | 130 | 500 | 350 | 200 | 200 | 2700 | 400 | 200 | 480 | 11/10.8 | 9 | 3800*1800*2700 |

| 135T/4000 | 1350 | 4000 | 170 | 220 | 10 | 130 | 500 | 350 | 200 | 200 | 3100 | 400 | 200 | 480 | 11/10.8 | 9.4 | 4600*1800*2700 |

| 135T/4100 | 1350 | 4100 | 170 | 220 | 10 | 130 | 500 | 350 | 200 | 200 | 3600 | 400 | 200 | 480 | 11/10.8 | 9.6 | 4700*1800*2700 |

| 170T/2500 | 1700 | 2500 | 300 | 160 | 10 | 100 | 500 | 350 | 200 | 200 | 2050 | 450 | 200 | 480 | 15/13.2 | 10.4 | 3100*2000*2800 |

| 170T/3200 | 1700 | 3200 | 300 | 160 | 10 | 100 | 500 | 350 | 200 | 200 | 2700 | 450 | 200 | 480 | 15/13.2 | 11.3 | 3800*2000*2800 |

| 170T/4000 | 1700 | 4000 | 300 | 160 | 10 | 100 | 500 | 350 | 200 | 200 | 3100 | 450 | 200 | 480 | 15/13.2 | 12.3 | 4600*2000*2800 |

| 170T/4100 | 1700 | 4100 | 300 | 160 | 10 | 100 | 500 | 350 | 200 | 200 | 3600 | 450 | 200 | 480 | 15/13.2 | 12.5 | 4700*2000*2800 |

| 220T/2500 | 2200 | 2500 | 300 | 160 | 9 | 105 | 500 | 350 | 200 | 200 | 2050 | 450 | 200 | 480 | 18.5/16.7 | 12 | 3100*2200*2850 |

| 220T/3200 | 2200 | 3200 | 300 | 160 | 9 | 105 | 500 | 350 | 200 | 200 | 2600 | 450 | 200 | 480 | 18.5/16.7 | 12.8 | 3800*2200*2850 |

| 220T/4000 | 2200 | 4000 | 300 | 160 | 9 | 105 | 500 | 350 | 200 | 200 | 3100 | 450 | 200 | 480 | 18.5/16.7 | 14 | 4600*2200*2850 |

| 220T/5000 | 2200 | 5000 | 300 | 160 | 9 | 105 | 500 | 350 | 200 | 200 | 4000 | 450 | 200 | 480 | 18.5/16.7 | 19 | 4600*2200*2850 |

| 250T/2500 | 2500 | 2500 | 460 | 100 | 8.5 | 100 | 500 | 350 | 200 | 200 | 2000 | 450 | 250 | 540 | 22/16.7 | 15.5 | 3100*2000*2900 |

| 250T/3200 | 2500 | 3200 | 460 | 100 | 8.5 | 100 | 500 | 350 | 200 | 200 | 2600 | 450 | 250 | 540 | 22/16.7 | 16.1 | 3500*2000*2900 |

| 250T/4000 | 2500 | 4000 | 460 | 100 | 8.5 | 100 | 500 | 350 | 200 | 200 | 3100 | 450 | 250 | 540 | 22/16.7 | 17.8 | 4300*2100*3100 |

| 250T/5000 | 2500 | 5000 | 460 | 100 | 8.5 | 100 | 500 | 350 | 200 | 200 | 3800 | 450 | 250 | 540 | 22/16.7 | 23.3 | 5300*2150*3150 |

| 250T/6000 | 2500 | 6000 | 460 | 100 | 8.5 | 100 | 500 | 350 | 200 | 200 | 4800 | 450 | 250 | 540 | 22/16.7 | 25 | 6300*2150*3150 |

| 300T/3200 | 3000 | 3200 | 650 | 80 | 8.5 | 110 | 500 | 350 | 200 | 200 | 2600 | 500 | 250 | 570 | 22 | 18.8 | 3500*2250*3200 |

| 300T/4000 | 3000 | 4000 | 650 | 80 | 8.5 | 110 | 500 | 350 | 200 | 200 | 3100 | 500 | 250 | 570 | 22 | 20.3 | 4300*2500*3400 |

| 300T/5000 | 3000 | 5000 | 650 | 80 | 8.5 | 110 | 500 | 350 | 200 | 200 | 3800 | 500 | 250 | 570 | 22 | 27 | 5300*2500*3400 |

| 300T/6000 | 3000 | 6000 | 650 | 80 | 8.5 | 110 | 500 | 350 | 200 | 200 | 4800 | 500 | 250 | 570 | 22 | 30.4 | 6300*2500*3400 |

| 400T/3200 | 4000 | 3200 | 760 | 80 | 8 | 80 | 980 | 220 | 200 | 40 | 2400 | 500 | 300 | 610 | 30 | 22.8 | 3500*2700*3500 |

| 400T/4000 | 4000 | 4000 | 760 | 80 | 8 | 80 | 980 | 200 | 200 | 40 | 3100 | 500 | 300 | 610 | 30 | 28.3 | 4300*2700*3500 |

| 400T/5000 | 4000 | 5000 | 760 | 80 | 8 | 80 | 980 | 200 | 200 | 40 | 3800 | 500 | 300 | 610 | 30 | 31.2 | 5300*2700*3500 |

| 400T/6000 | 4000 | 6000 | 760 | 80 | 8 | 80 | 980 | 200 | 200 | 40 | 4800 | 500 | 300 | 610 | 30 | 37.4 | 6300*2700*3500 |

| 400T/8000 | 4000 | 6000 | 760 | 80 | 8 | 80 | 980 | 200 | 200 | 40 | 6400 | 500 | 300 | 610 | 30 | 52.8 | 6300*2700*3500 |

| 500T/4000 | 5000 | 4000 | 760 | 80 | 8.5 | 90 | 980 | 220 | 200 | 40 | 3100 | 500 | 300 | 610 | 37 | 35 | 4300*2700*3500 |

| 500T/5000 | 5000 | 5000 | 760 | 80 | 8.5 | 90 | 980 | 200 | 200 | 40 | 3800 | 500 | 300 | 610 | 37 | 39.8 | 5300*2700*3500 |

| 500T/6000 | 5000 | 6000 | 760 | 80 | 8.5 | 90 | 980 | 200 | 200 | 40 | 4800 | 500 | 300 | 610 | 37 | 45.8 | 6300*2700*3600 |

| 600T/3200 | 6000 | 3200 | 1050 | 80 | 8.5 | 85 | 980 | 200 | 200 | 40 | 2300 | 600 | 320 | 650 | 45 | 45 | 4300*3300*3900 |

| 600T/4000 | 6000 | 4000 | 1050 | 80 | 8.5 | 85 | 980 | 200 | 200 | 40 | 3100 | 600 | 320 | 650 | 45 | 45.8 | 4300*3300*3900 |

| 600T/5000 | 6000 | 5000 | 1050 | 80 | 8.5 | 85 | 980 | 220 | 200 | 40 | 3800 | 600 | 320 | 650 | 45 | 50.3 | 5300*3300*3900 |

| 600T/6000 | 6000 | 6000 | 1050 | 80 | 8.5 | 85 | 980 | 200 | 200 | 40 | 4800 | 600 | 320 | 650 | 45 | 56.8 | 6300*3300*3900 |

| 600T/7000 | 6000 | 7000 | 1050 | 80 | 8.5 | 85 | 980 | 200 | 200 | 40 | 5600 | 600 | 320 | 650 | 45 | 66.8 | 7300*3300*3900 |

| 700T/6000 | 7000 | 6000 | 1050 | 80 | 8.5 | 85 | 980 | 200 | 200 | 40 | 4900 | 600 | 320 | 700 | 55 | 66.8 | 6300*3500*4000 |

| 800T/6000 | 8000 | 6000 | 1800 | 80 | 8 | 90 | 980 | 220 | 200 | 40 | 4600 | 600 | 320 | 800 | 30*2 | 76.8 | 6300*3500*4000 |

| 800T/7000 | 8000 | 7000 | 1800 | 80 | 8 | 90 | 980 | 200 | 200 | 40 | 5600 | 600 | 320 | 800 | 30*2 | 7300*3500*4200 | |

| 800T/8000 | 8000 | 8000 | 1800 | 80 | 8 | 90 | 980 | 200 | 200 | 40 | 6600 | 600 | 320 | 800 | 30*2 | 8300*3600*4500 | |

| 800T/10000 | 8000 | 10000 | 1800 | 80 | 8 | 90 | 980 | 200 | 200 | 40 | 7800 | 600 | 320 | 800 | 30*2 | 10300*3600*4900 |