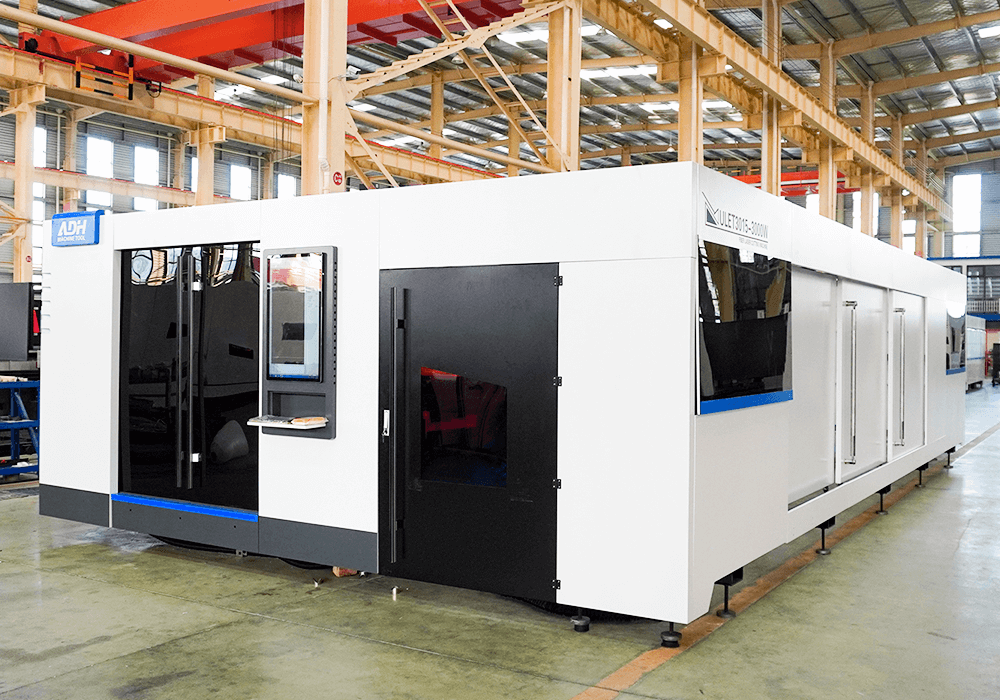

| Model | ULFT/ULET |

|---|---|

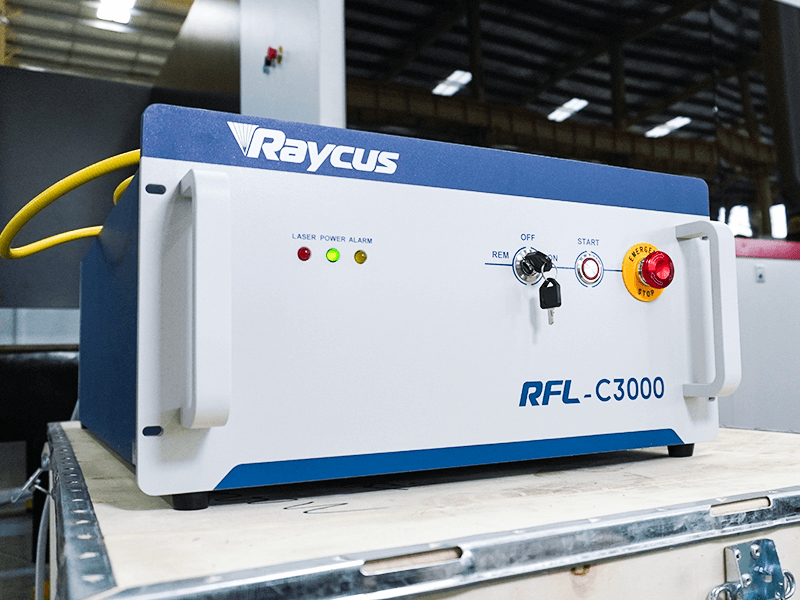

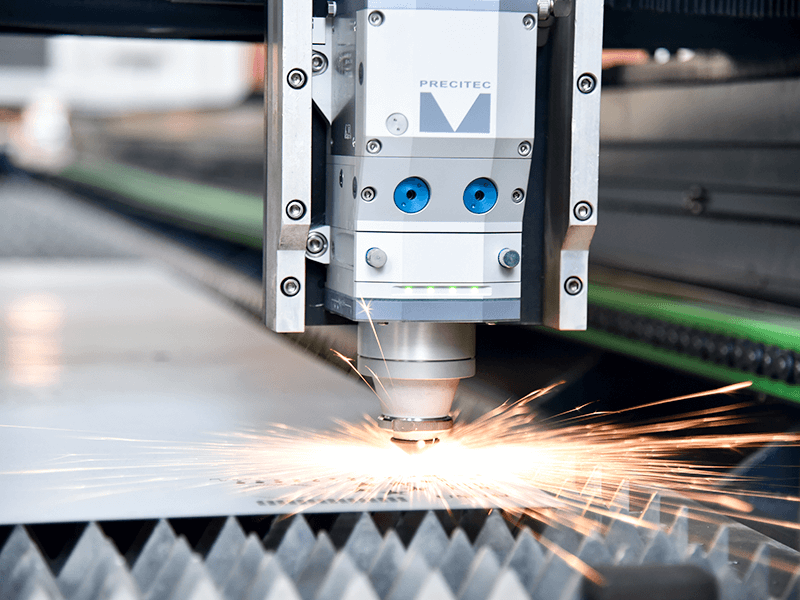

| Laser power | 1500W/3000W/6000W |

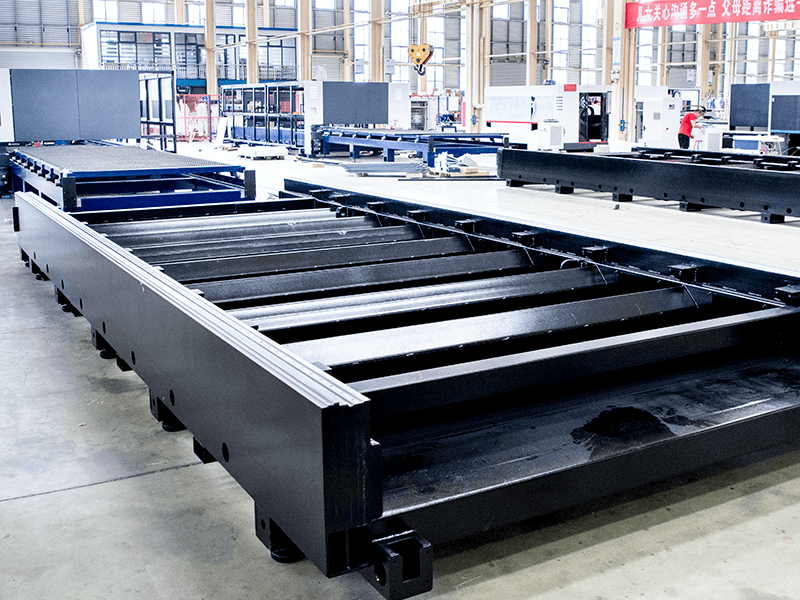

| Cutting range | 3*1.5(m)/4*1.5(m)/6*1.5(m)/6*2.0(m)/6*2.5(m) |

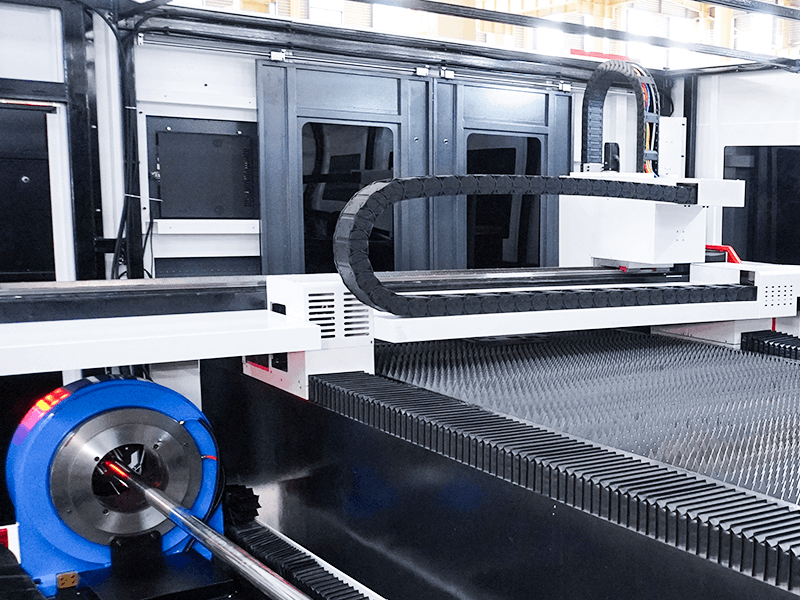

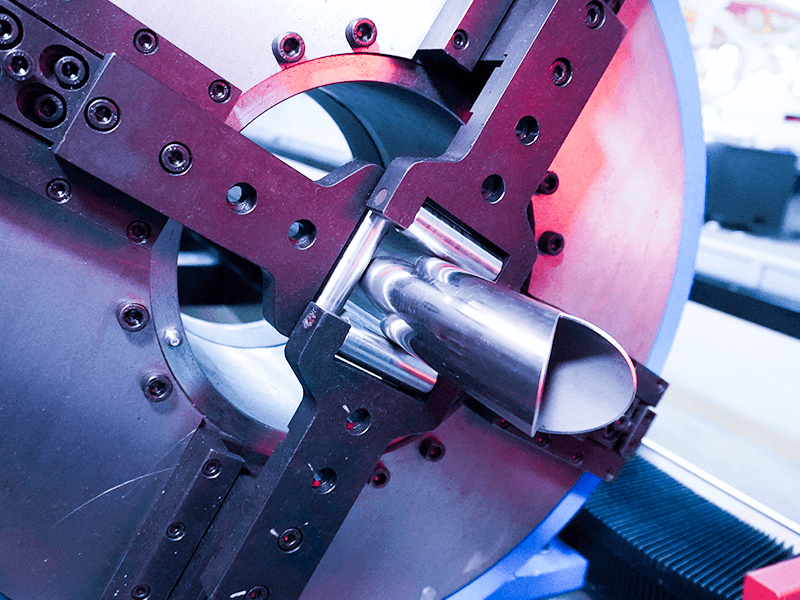

| Maximum size of chuck | 220mm/350mm |

| Plate/tube cutting length | 3000mm/4000mm/6000mm |

| Maximum moving speed | 90m/min |

| Maximum acceleration | 1.2g |

| Positioning accuracy | ±0.05mm |

| Repeated positioning accuracy | ±0.02mm |

| Operating voltage | 380V/50Hz |

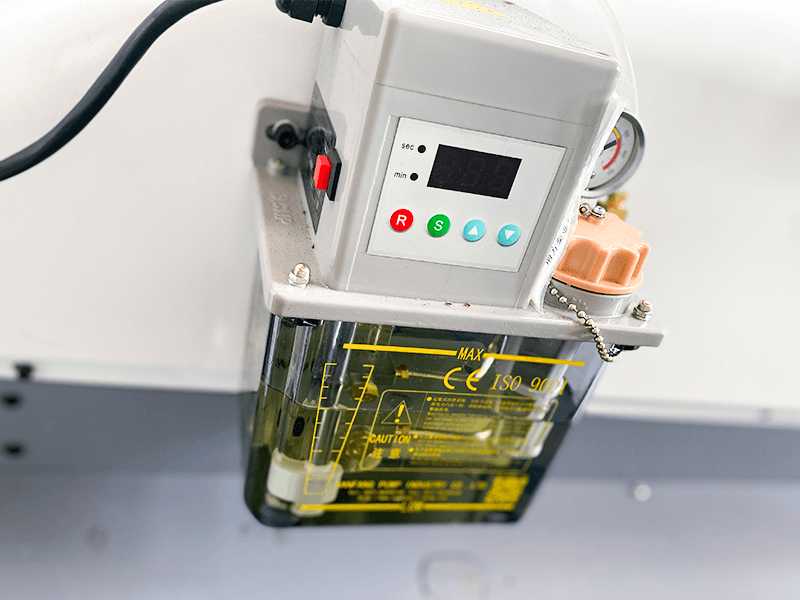

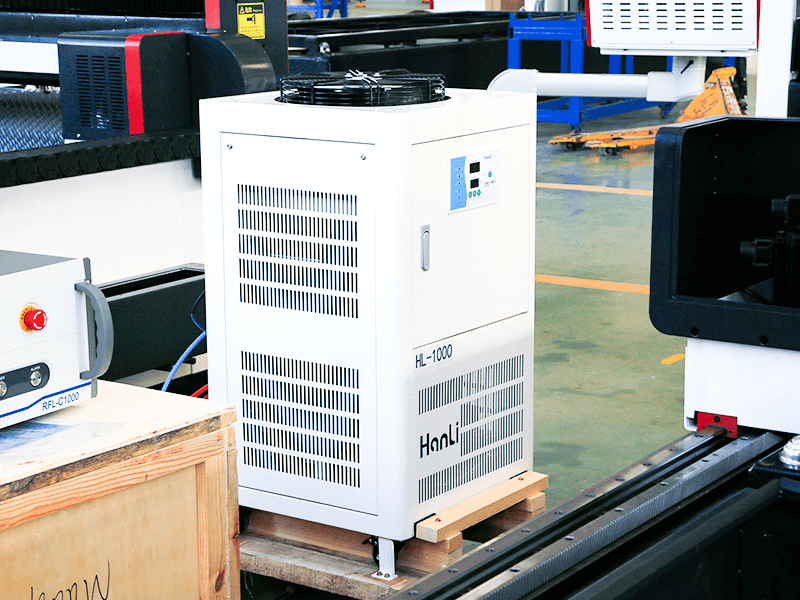

| Cooling method | water-cooled |