¿Qué es una plegadora?

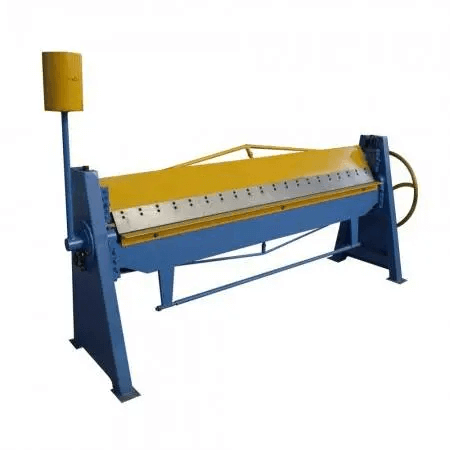

Prensa plegable es una máquina utilizada para doblar y conformar metales.

Acciona punzones y matrices a través de diferentes fuentes accionadas para doblar chapa metálica repetidamente y formar perfiles.

Los materiales de diferentes espesores y longitudes requieren diferentes fuerzas de flexión.

La fuerza de plegado, medida en tonelaje, es la fuerza ejercida por la plegadora. Los distintos tipos de plegadoras producen tonelaje de formas diferentes.

La prensa plegadora hidráulica es adecuada para el plegado con gran tonelaje, mientras que las fuentes accionadas se dividen generalmente en tipos mecánicos, hidráulicos, eléctricos y neumáticos.

El nombre de la prensa plegadora viene determinado por el método de accionamiento.

Por ejemplo, la plegadora neumática acciona el cilindro mediante presión de aire, mientras que la servoeléctrica acciona el cilindro mediante un servomotor.

La plegadora servoeléctrica ofrece una precisión y velocidad muy elevadas.

¿Cómo funciona una plegadora?

Las prensas plegadoras modernas pueden dividirse principalmente en prensas plegadoras mecánicas e hidráulicas.

En la actualidad, la prensa plegadora se ha convertido en la avanzada prensa plegadora hidráulica CNC, que puede manejar todo tipo de tareas de formación de piezas de trabajo complejas y masivas.

La prensa mecánica impulsa el volante de inercia a través del motor.

El operador acciona el embrague para controlar el volante, y la manivela impulsa el movimiento de otras piezas.

El funcionamiento de la prensa plegadora mecánica es relativamente sencillo, y puede manejar grandes tonelajes de plegado.

La prensa hidráulica es impulsado por el movimiento sincrónico del cilindro hidráulico.

Hay un cilindro hidráulico a cada lado de los montantes, y el cilindro hidráulico está conectado al ariete a través del vástago del pistón.

El movimiento del cilindro hidráulico impulsa el ariete hacia arriba y hacia abajo.

Los modos de movimiento de la prensa hidráulica se dividen en movimiento ascendente y movimiento descendente.

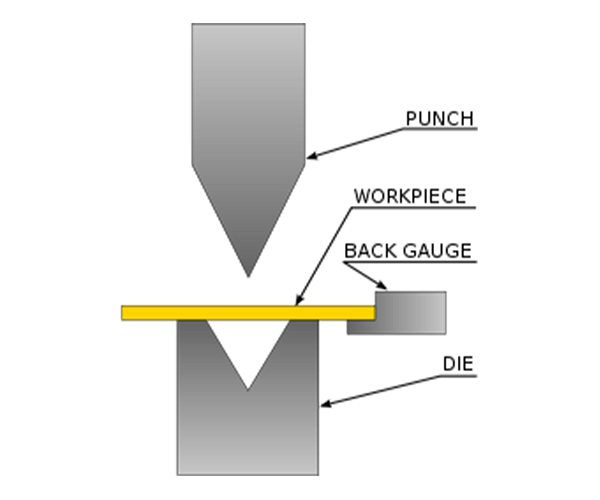

Los calibradores traseros posicionan con precisión la pieza mediante el movimiento de diferentes ejes. La prensa hidráulica tiene las ventajas de la alta velocidad y la alta precisión.

Sin embargo, el tonelaje de curvado es limitado, lo que supone una desventaja.

El CNC prensa plegable es una plegadora hidráulica equipada con un sistema de control CNC que controla el movimiento de cada pieza con funciones de programación modular y alta precisión.

El operario puede ajustar los parámetros a través del sistema de control. Por ejemplo, el ángulo de plegado, el grosor de la placa, la longitud de la brida, el tiempo de ciclo, la tensión, etc.

Además, el Plegadora CNC también está equipada con un sistema de alimentación automático que controla con precisión la posición de la pieza mediante el movimiento del cilindro y el tope trasero.

Movimiento sincrónico de los ejes de accionamiento del motor del tope trasero y de los husillos de bolas. El calibrador trasero puede medir con precisión la longitud de la brida que se está formando.

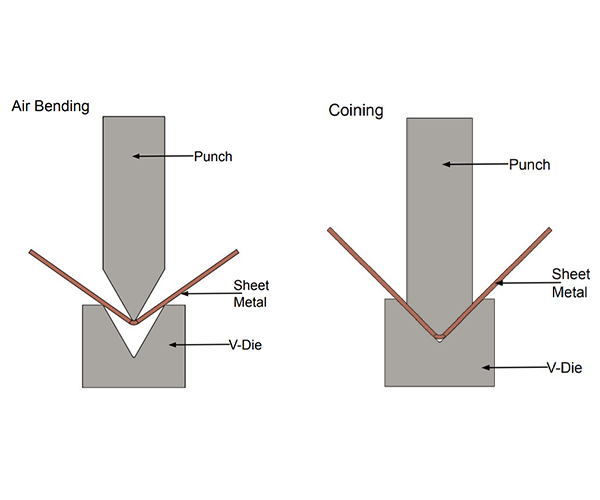

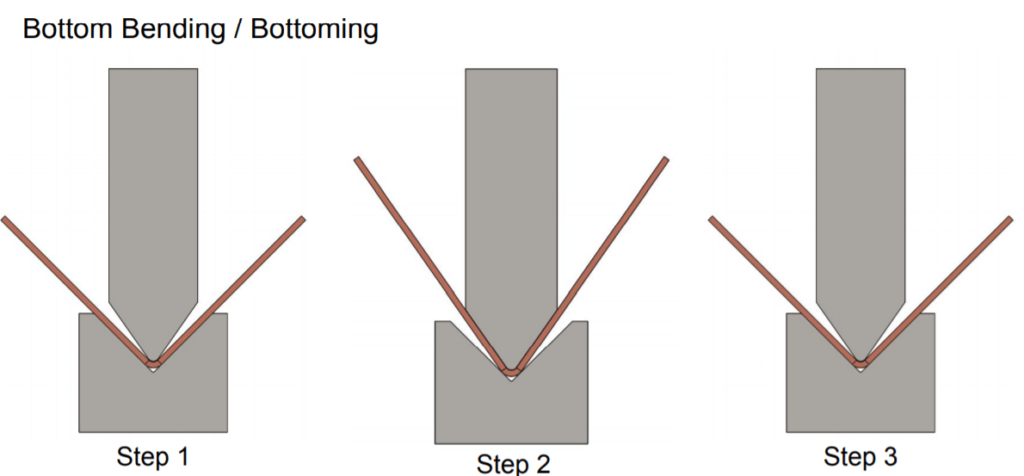

Ajuste el ángulo de curvatura ajustando el movimiento del pistón a través del sistema de control. Hay básicamente tres métodos de flexión: curvado por aire, curvado de fondo y curvado en relieve.

La elección del método de doblado tiene una gran relación con el espesor de la placa.

El plegado por aire es el método de plegado más utilizado, en el que la pieza no está en pleno contacto con la matriz inferior. Puede realizarse con un tonelaje relativamente pequeño.

En caso necesario, también se pueden utilizar métodos de doblado y acuñado del fondo.

Durante el plegado, los cilindros hidráulicos accionan el movimiento del cilindro, que a su vez acciona la matriz superior para ejercer presión sobre la matriz inferior situada en el banco de trabajo.

La chapa del centro se forma en un ángulo específico mediante la extrusión de la matriz y, tras doblarla repetidamente, se obtiene el perfil final.

El ángulo y la forma de la placa metálica vienen determinados por la forma de los punzones y las matrices, así como por el movimiento del cilindro.

La plegadora CNC ofrece un control numérico flexible y funciones de programación que facilitan su manejo.

¿Cómo se monta una prensa plegadora?

En primer lugar, es fundamental comprender el dibujo de la pieza a doblar.

Determine el material, la longitud y el grosor de la pieza, así como el ángulo de flexión, el radio de flexión, la dimensión de la brida y la tolerancia de la pieza.

En segundo lugar, hay que elegir el método de plegado y la matriz adecuados.

Seleccione el método de curvado adecuado en función de la relación entre el radio de curvado y el grosor del metal, como el curvado por aire, el curvado de fondo o el acuñado.

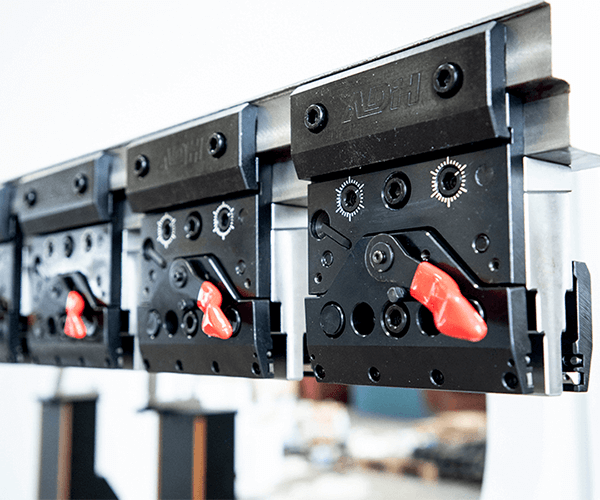

Elija punzones y matrices que coincidan con el material de la pieza de trabajo de plegado.

En tercer lugar, determine el tonelaje según la tabla de tonelaje.

Consulte la estimación de tonelaje correspondiente facilitada por el fabricante.

Si se trata de un doblado por aire, puede consultar la tabla de tonelaje para determinar el tonelaje.

El tonelaje de curvado inferior es de cuatro a seis veces superior al de curvado al aire, y el tonelaje de acuñado es de ocho a diez veces superior al de curvado al aire.

Instalar y ajustar los utillajes, incluida la comprobación del grosor y la proporción de las matrices superior e inferior, el ajuste de la carrera del cilindro, el ajuste del punto límite superior de los utillajes para reservar la posición de permanencia del cilindro y el ajuste de una separación adecuada entre las matrices superior e inferior.

Realice el procedimiento de programación de la plegadora, familiarizándose con las funciones del controlador CNC, programando fuera de línea y utilizando placas de desecho para una prueba de plegado.

Si hay algún problema con la pieza doblada, compruebe y corrija el programa, y haga funcionar la plegadora en consecuencia. Estos pasos pueden ahorrar costes y mejorar la eficiencia.

Conclusión

Hay muchos tipos de plegadoras, como las plegadoras mecánicas, las plegadoras CNC, las plegadoras hidráulicas, etc.

Independientemente de lo avanzada que sea la tecnología de la prensa plegadora, su principio básico de funcionamiento es similar.

La moderna prensa plegadora CNC es más avanzada que la tecnología de la prensa plegadora anterior, y la precisión y la eficiencia del plegado se han mejorado mucho.

ADH produce varias plegadoras CNC, plegadoras NC y plegadoras de gran tamaño. Puede consulte a nuestros expertos en productos para saber más sobre nuestra prensa plegadora u otras máquinas.