What Is Sheet Metal Bending?

Sheet metal bending involves using machines and tools to form metal into a specific shape.

This can be achieved through the use of a press brake, punching machine, ironworker, or other machinery.

These machines utilize a power system to drive the tooling and apply pressure on the metal sheet, causing it to deform.

To ensure accurate results in sheet metal bending, several parameters must be determined before the process begins.

These parameters include the material thickness, bending radius, bending allowance, bending deduction, K factor, and others.

It is important to keep in mind that different materials have varying properties such as tensile strength and ductility.

Different machines may use different bending methods to produce the same profile from a metal sheet.

Therefore, it's crucial to choose the right machine and approach based on the specific requirements and parameters of the project.

What Are the Methods of Sheet Metal Bending?

The sheet metal bending process results in different bending shapes based on the angle and radius of the bend.

To ensure precision in the bending process, standard bending methods are employed. These methods vary, but they all aim to produce uniform standards in the final profiles.

Let's take a look at some of the main bending methods in sheet metal bending:

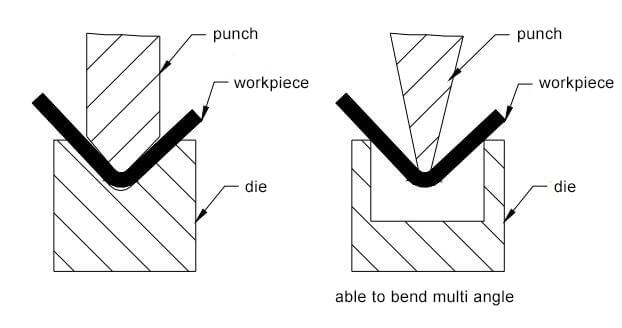

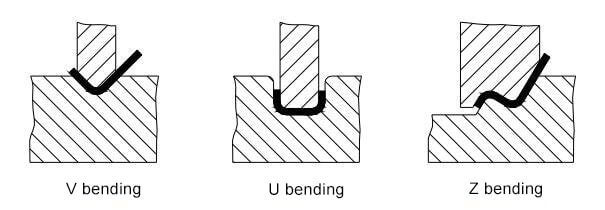

V-Bending - This is the most common bending process and is named so because of the V-shaped punch and die used in the process. The punch presses the metal sheet into the lower die, resulting in a V-shaped workpiece.

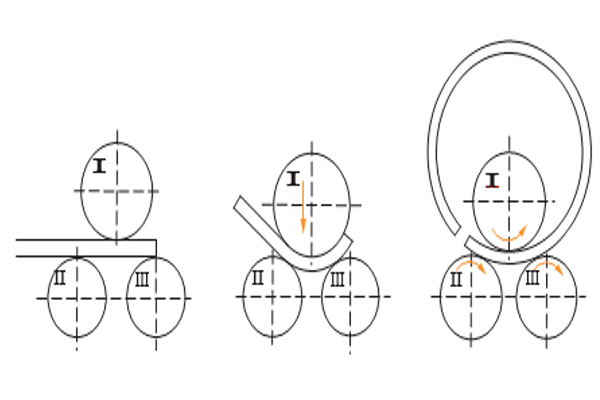

Roll Bending - This process is used for bending workpieces with large curls and involves the use of three rolls driven by a hydraulic system to bend the sheet.

U-Bending - This method involves using a U-shaped die to bend the workpiece. The punch is powered by a system to press the metal sheet into the U-shaped die, resulting in U-shaped profiles.

Rotary Bending - This method can bend the workpiece with a degree of more than 90. The final profile is similar to a V-bend, but the profile surface is smoother.

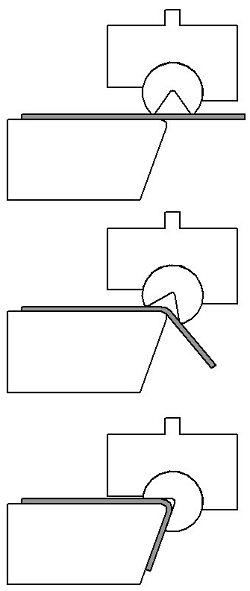

Edge Bending - This method is used in panel bending and involves the use of upper and lower molds that move up and down for bending. It's usually used for shorter metal sheets to reduce sharpness and prevent damage to the bending edge.

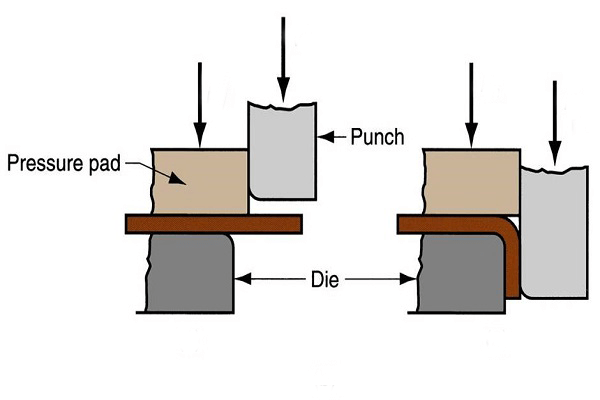

Wipe Bending - This method is similar to edge bending. The metal sheet is placed on the lower die and pressure is applied to the protruding metal by a pressure pad and punch, resulting in bending."

What Materials Are Fit for Sheet Metal Bending?

The choice of material for bending is crucial for achieving desired bending results.

Some materials may not be suitable for bending and could result in fracture or damage to the tooling. Materials with low ductility can be heated to reduce the risk of fracture.

When selecting materials for bending, it's important to consider their characteristics.

Here are some common materials used in sheet metal bending and their properties:

- Carbon steel: This material is strong and flexible with good ductility, and is an environmentally friendly option that can be recycled.

- Mild steel: Mild steel has excellent ductility, which allows it to bend smoothly without heating.

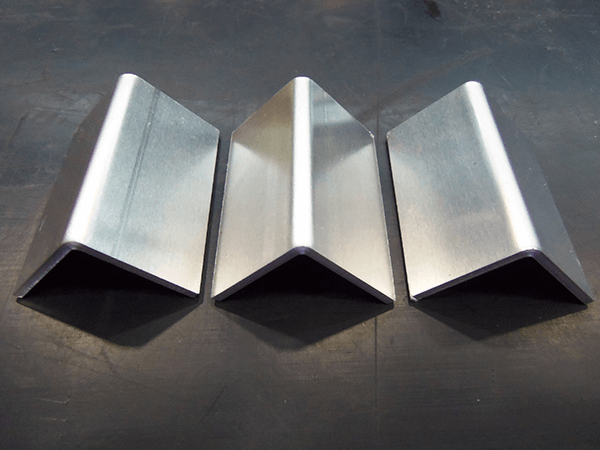

- Stainless steel: This material is strong, corrosion-resistant, and has high tensile and yield strength, making it a popular choice for bending.

- Titanium: Titanium has a high tensile strength but can be prone to damage the tooling if not used properly. When bending titanium, it is necessary to increase the internal bending radius to prevent cracking and to overbend the material to achieve the desired shape.

- Aluminum: Aluminum is prone to cracking when bent, so it's important to anneal it to prevent cracking. When bending aluminum, it's important to avoid over-bending to reduce the risk of cracking.

- Copper: Copper has high ductility, making it a great choice for bending, and is cost-effective. It is widely used in the sheet metal processing industry.

Stainless Steel Sheet Bending

Features of Stainless Steel

Steel is a combination of materials, including small amounts of carbon, manganese, silicon, copper, phosphorus, sulfur, and oxygen.

It is classified based on the carbon content as high, medium, low, and ultra-low carbon steel.

Steel can be bent easily as the tools used for bending steel plates are also made of steel.

However, bending stainless steel requires a relatively larger force due to its high yield strength, hardness, and poor ductility.

Additionally, the springback of stainless steel after bending is significant, hence requiring a larger bending radius to avoid cracking the workpiece.

Considerations for Bending Stainless Steel Sheet

Plate Thickness and Bending Tonnage Before bending stainless steel, it is essential to determine the thickness of the plate. Thicker plates require a larger bending machine.

Bending Angle and Bending Radius

The bending angle and radius are crucial to consider.

A larger bending radius may result in excessive springback, while a smaller radius may cause cracking.

Generally, the bending radius is around 0.2. For materials like high-carbon steel, a larger inner radius is necessary to prevent cracking.

Stainless steel has high resilience, and the bending angle and radius cannot be too small.

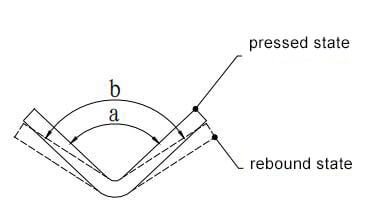

Bending Springback

The springback of a metal plate is proportional to the material's yield strength and inversely proportional to its elastic modulus.

Low-carbon steel has less springback and is ideal for high-precision workpieces, while high-carbon steel and stainless steel have significant springback.

The larger the bending radius, the greater the springback.

Smaller bending radii result in higher accuracy.

Calculating the Bending Allowance

The bending allowance, which is the expansion of the outer side of the sheet, can be calculated with the knowledge of the sheet thickness, bending angle, and inner radius.

This calculation determines the required length of the sheet for bending.

The formula for calculating the bending allowance is: BA=(π/180) x B x (IR+K x MT), or use a bending allowance gauge.

Bending with Machines

Finally, a machine like a press brake can be used for bending processing.

If the metal sheet is prone to cracking, it can be hot-formed or annealed.

Annealing improves the ductility of metals by softening them, and hot bending involves heating the metal to a red state and then bending it.

Conclusion

This blog post provides an overview of the basics of sheet metal bending, with a focus on important considerations for bending stainless steel.

Metal bending can be achieved using various machines, including press brakes. For simple bending tasks, a vise can also be used.

ADH is a manufacturer of sheet metal processing machines with 20 years of experience in the industry.

If you are in need of press brakes or other such machinery, you can reach out to one of our sales representatives for more information on the products and their prices.

FAQ

How to Bend Stainless Steel Sheet Without a Brake?

First, gather the necessary materials including stainless steel plates, hammers, vises, rulers, protractors, and markers.

Use the ruler to measure the plate's thickness, calculate the K factor and inner radius, and then determine the bend allowance using the formula BA=(π/180) x B x (IR+K x MT).

Use the protractor and marker to mark the bending line and radius on the plate.

Cut the stainless steel plate to the appropriate size, and use the vise to bend the plate to the desired angle.

Ensure an even bend by striking the metal with a wooden hammer.

Check the bend angle and bend allowance for accuracy. If necessary, you can assist the bend by heating the metal.

How to Calculate Bend Allowance?

Remember that bending the metal under pressure will result in internal compression and external stretching.

When calculating the bend dimension, be sure to take into account the bend allowance which is dependent on the sheet thickness, inner radius, K factor, and bending angle.

The formula to calculate the bend allowance is BA=(π/180) x B x (IR+K x MT), where K is the K factor, B is the bending angle, IR is the internal radius, and MT is the plate thickness.