Our company's latest development, the highly flexible all-round

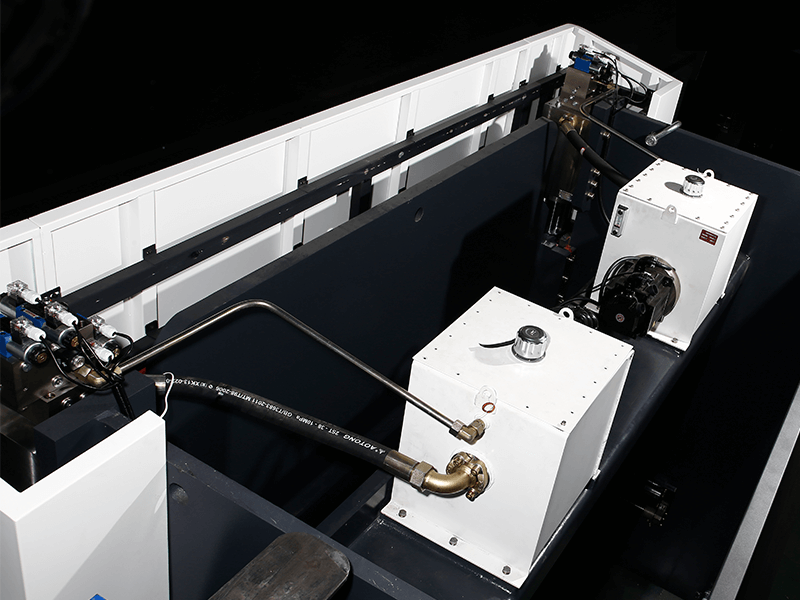

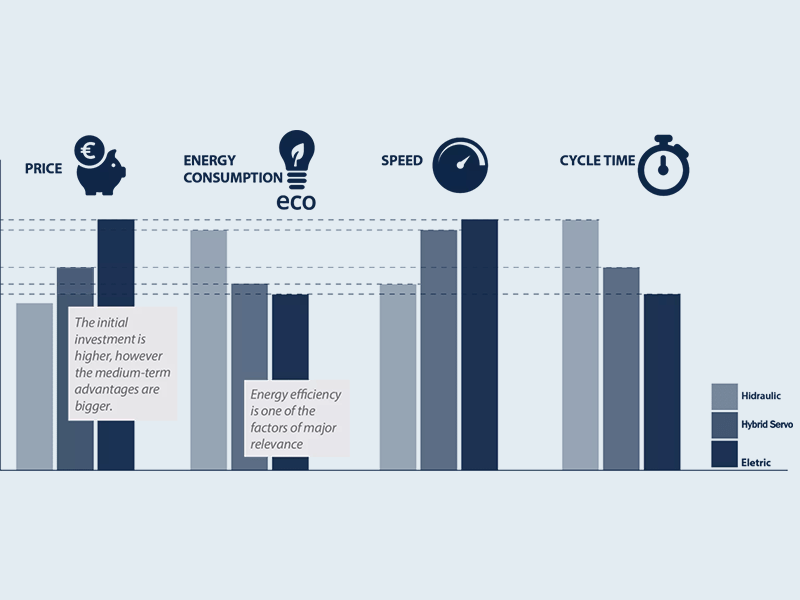

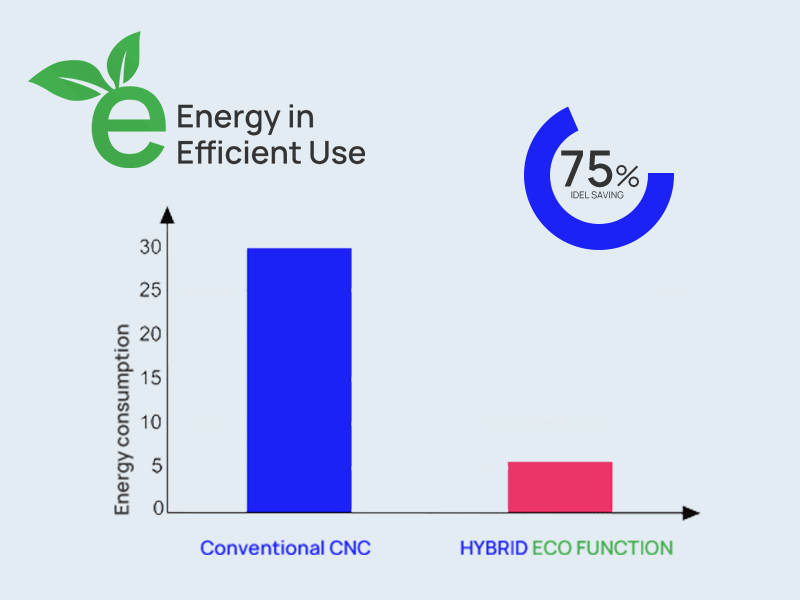

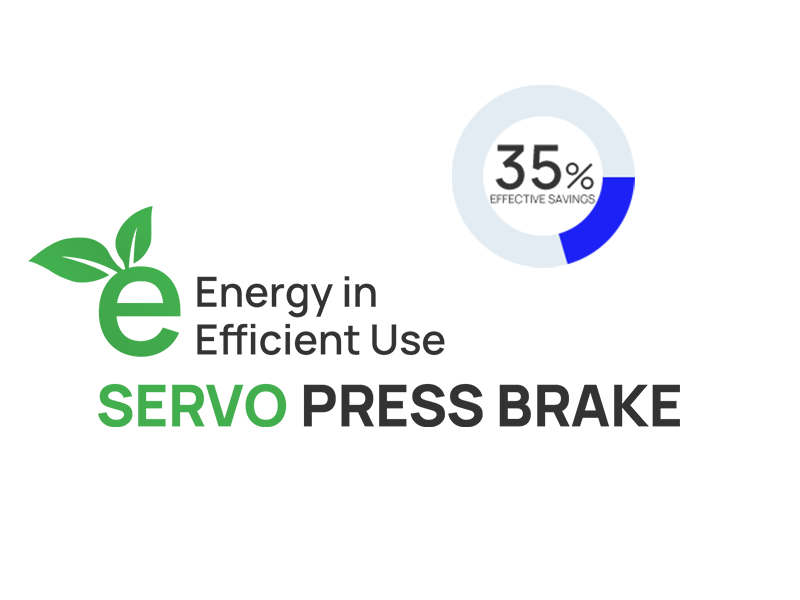

CNC press brake, combines new technical innovations with proven technology and expertise gained through years of experience and passion at ADH. Among its outstanding features are a highly dynamic hybrid-servo drive system and a user-friendly control interface.

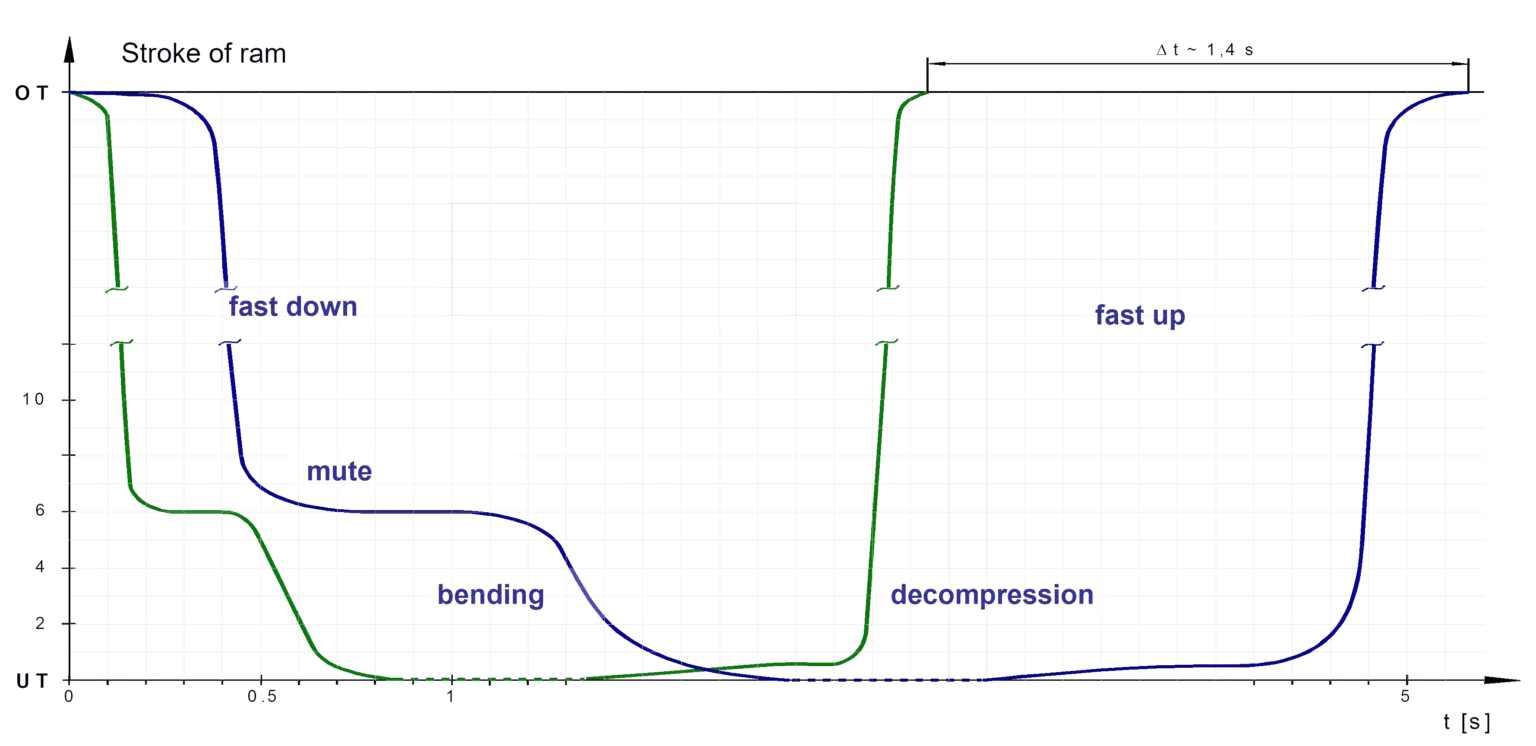

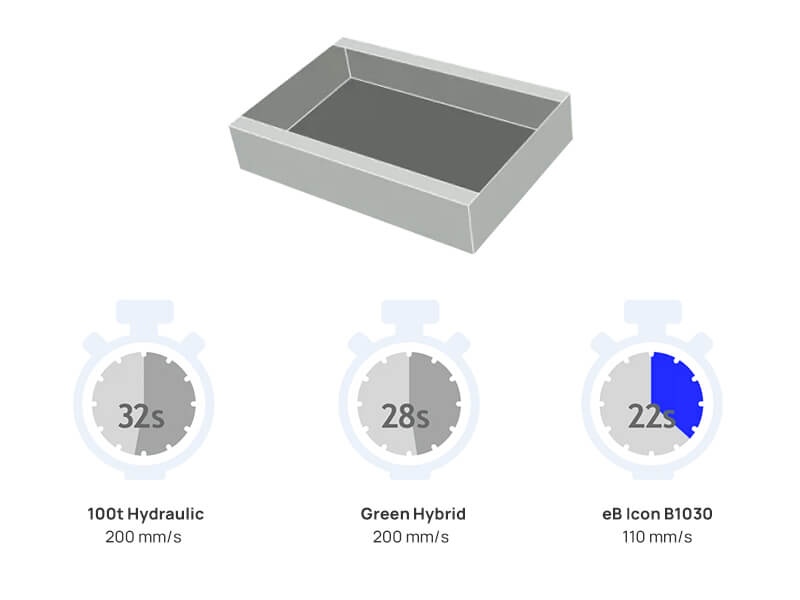

The hybrid press brake's hybrid servo drive system delivers high acceleration, deceleration, and fast response times, resulting in significant gains in productivity when compared to conventional press brakes. Real-world cycle time reductions of up to 30% or more are achievable with this technology.