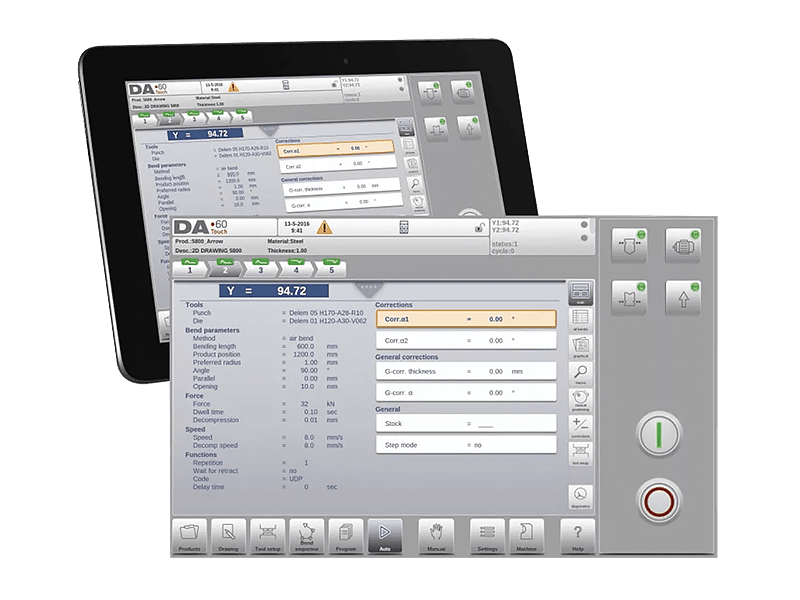

Additional Control Panel (ACP)

With the ACP (Additional Control Panel) option, a supplementary operator panel can be linked to a DA-60Touch control. The ACP can be a Windows PC or tablet, and the linkage between the DA-60Touch control and ACP occurs via Ethernet. The control software has integrated all components necessary to run the ACP client on any Windows tablet or integrated Windows PC. Once the software option (OP-W-ACP) is enabled, the control will synchronize with the ACP and deliver complete control functions.

Get Quote