What Are CNC Press Brake and NC Press Brake?

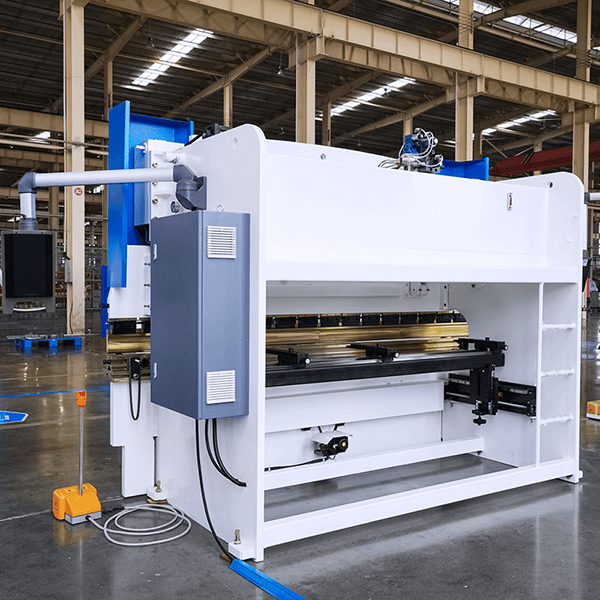

An NC press brake or CNC press brake is a type of press brake that uses a CNC system to control the bending process.

With the CNC system, the operator can program various bending parameters of the workpiece through the controller.

The controller can then set all parameters, allowing for repeated bending to be performed accurately and efficiently.

The main difference between the NC press brake and the CNC press brake is that the latter has a more advanced controller.

This allows for complex programming to be carried out, leading to higher accuracy and automation levels.

The CNC press brake is better suited for complex workpieces and mass production.

Advantages and Disadvantages of NC press brake

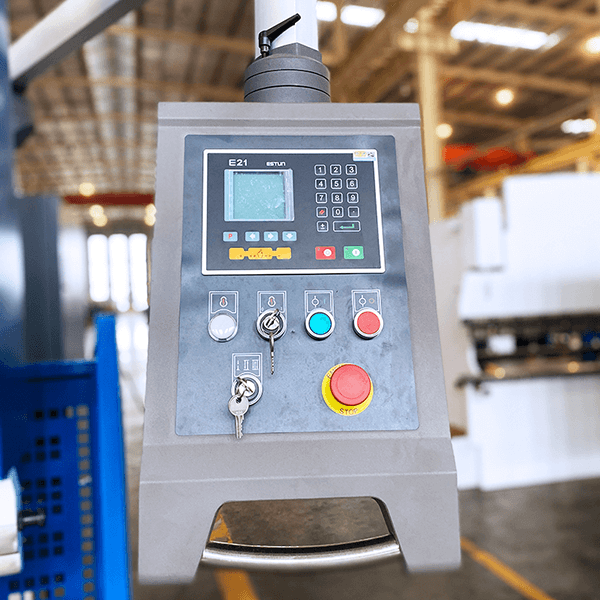

The NC press brake uses an NC system to control the up-and-down movement of the punch and bend the metal sheet.

It has several advantages over manual press brakes, including improved consistency in bending speed and accuracy, and reduced reliance on skilled operators.

In comparison to manual press brakes, NC press brakes significantly increase bending speed and precision.

The NC system is used to control various aspects of the bending process, such as stroke speed and the number of bends.

This allows for repeated bending to be performed consistently, with a focus on both speed and precision.

The NC press brake can enhance the production efficiency of parts and ensure the quality of the final products.

Furthermore, the NC press brake reduces the skill requirements for operators in comparison to manual press brakes.

Manual press brakes require the operator to manually set up the machine and adjust the die, whereas with NC press brakes, most bending programs can be completed by programming the controller or setting parameters.

The operator's role is mostly limited to loading and unloading sheet metal.

Once the NC system is programmed, the NC press brake can also perform automatic bending, following the set procedures and steps to improve production efficiency.

While the NC press brake has higher initial costs for machine purchase and personnel training, it is not as efficient as a skilled operator in handling emergencies or complex bending.

It is important to note that although the NC press brake has greater automation capabilities, it still requires a certain level of skill and knowledge to operate effectively.

Advantages and Disadvantages of CNC Press Brake

The CNC press brake, or computer numerical control press brake, is used for bending metal sheets.

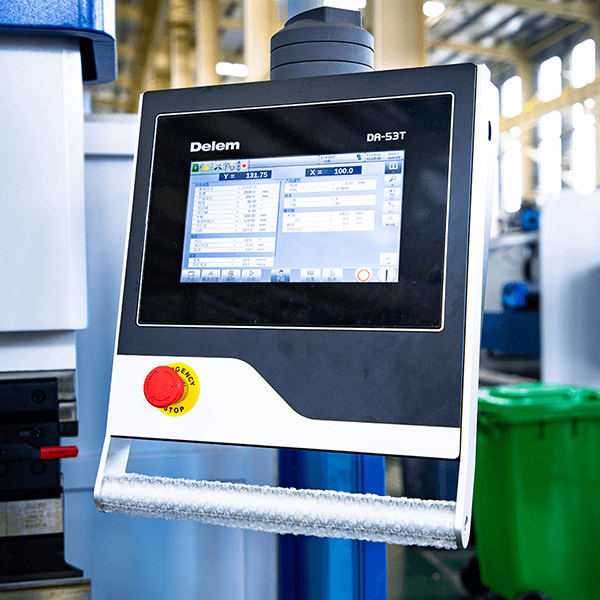

Compared to the NC press brake, the CNC press brake has a more advanced CNC system that results in higher bending speed, precision, and automation.

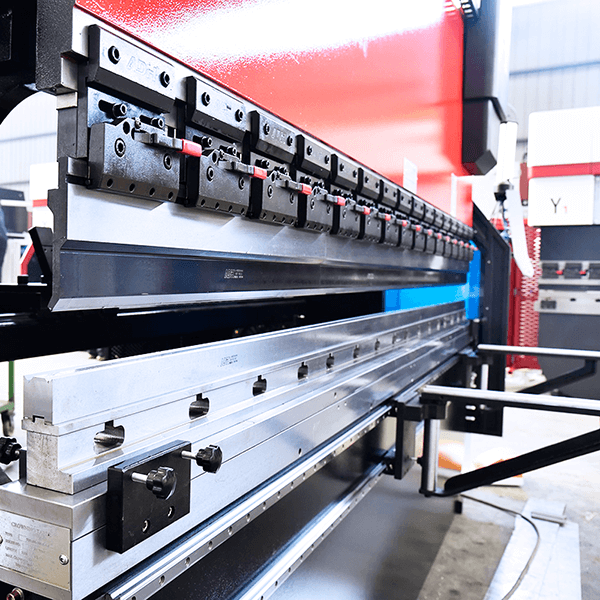

The CNC press brake's more advanced controller allows for more accurate bending, with the ability to achieve precise bending speed, angle, and a final accurate workpiece.

This improved accuracy and quality of the workpiece help to reduce production costs.

The CNC press brake is also capable of producing workpieces with more complex shapes, thanks to its advanced CNC controller that can be programmed through complex algorithms.

This allows for greater control of the bending accuracy of the die, which is useful when processing workpieces with complex shapes and angles.

The CNC press brake has a higher degree of automation than the NC press brake.

With the ability to program complex workpieces, the CNC press brake can bend according to the pre-determined program.

A more advanced version of the CNC press brake is a bending center equipped with a robotic arm.

The CNC press brake is ideal for complex bending, increasing output and efficiency.

However, the CNC press brake also has a higher cost, with higher purchase and training expenses compared to NC press brakes.

The operation of a CNC press brake is more complex, requiring higher skills from the operators.

CNC press brakes are best suited for complex workpiece bending or factories with high-volume production requirements.

Due to its high accuracy, the processed workpiece often requires minimal rework.

Comparison of NC Press Brake and CNC Press Brake

One of the differences between CNC press brake and NC press brake lies in the functionality and accuracy of their control systems.

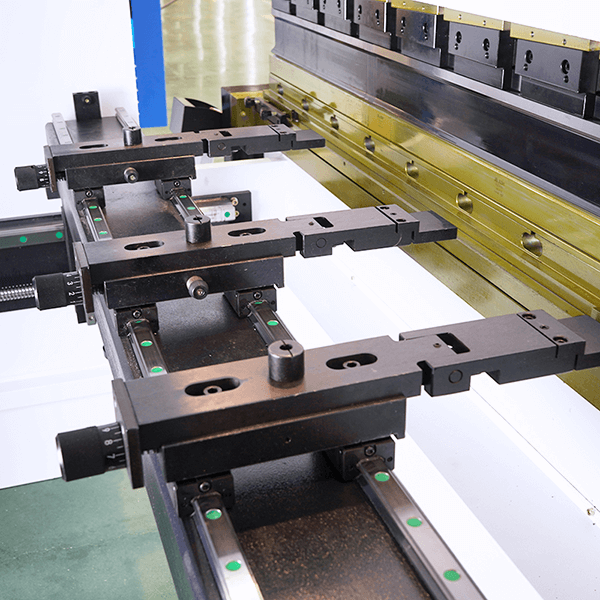

NC press brake primarily controls the bending process through its NC system, while the controller of the CNC press brake is managed by a computer control system, allowing for the programming of complex algorithms and precise control of the dies, back gauge, and other components.

Another difference between the two is the level of automation; the CNC press brake has a higher degree of automation with features such as a robotic arm, requiring the operator to only feed and unload material.

Although NC press brake is more affordable, it is suitable for the majority of metal sheet bending.

On the other hand, while CNC press brake may be more expensive, it offers a high level of automation and bending accuracy, capable of processing large quantities of complex workpieces.

Conclusion

"This blog post explores the advantages, disadvantages, and differences between CNC press brakes and NC press brakes.

In general, CNC press brakes are more advanced than NC press brakes and offer greater accuracy and higher quality products.

However, NC press brakes have a high cost-performance ratio and are more affordable than CNC press brakes, yet still possess complete functions and high bending accuracy.

If you are interested in purchasing a CNC press brake or an NC press brake, you can contact the product experts.

ADH is a professional manufacturer of sheet metal processing machines and offers cost-effective products and high-quality services.

FAQs

What Are the World's Famous Press Brake Manufacturers?

The global demand for sheet metal processing continues to grow, and as a result, the press brake market is also growing.

With so many press brake manufacturers to choose from, it can be difficult to select the right brand.

Famous brands such as Amada, Trumpf, Accurpress, Bystronic, Durma, Salvagnini, LVD, and Prima are among the world-renowned press brake manufacturers.

These brands offer a guarantee of quality and after-sales service but come at a higher cost.

Alternatively, you can opt for a less well-known brand that offers cost-effective options and meets your specific needs.

What Is A Hydraulic Press Brake?

Hydraulic press brakes are a type of press brake that use hydraulic devices for power.

The main components of hydraulic press brakes include the hydraulic device, ram, punch and die, controller, etc.

The hydraulic press brake has two hydraulic cylinders that are driven by the motor to provide the driving force.

Hydraulic press brakes have high speeds, low resistance, high bearing capacity, and large pressure.

They come in various types with different motors and tonnages to handle materials with different characteristics.