Press machines are a series of machines utilized in the sheet metal processing industry, with diverse types and functions.

The press machine is primarily employed to alter the form and size of metal plates through pressure, resulting in the final workpiece.

Two common machines used for sheet metal manufacturing are the press brake and punch press.

While they both have similar functions and can carry out various processing processes to produce final profiles, each machine has its own set of advantages and disadvantages and operates differently.

In this blog post, we will compare and contrast the differences, advantages, and disadvantages of these two sheet metal manufacturing processes to provide a better understanding.

What Is Press Brake?

Press brake is a widely used machine in the sheet metal processing industry.

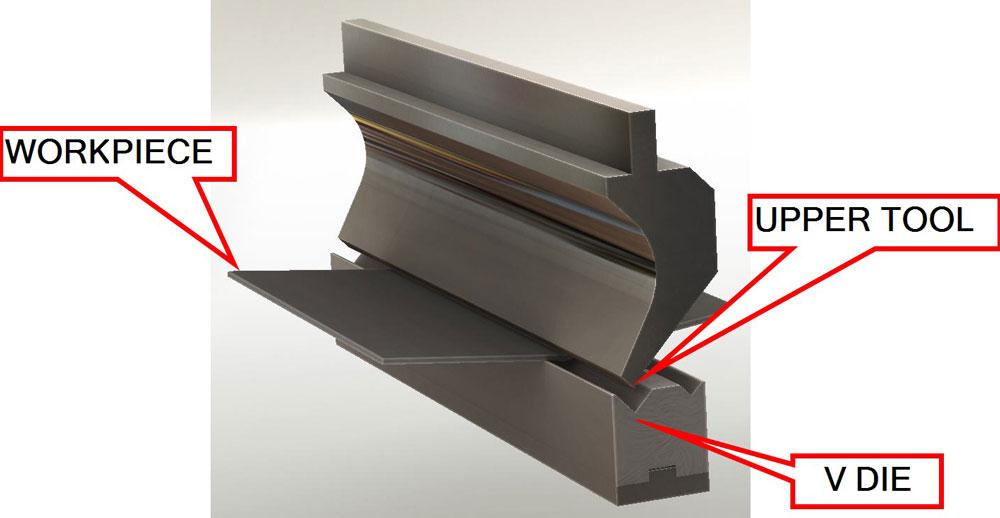

The standard configuration of a press brake typically includes a driving device, ram, workbench, punch, and die.

The ram drives the upper die to press down on the metal plate, thereby completing the bending process.

The press brake can be adjusted for multiple bends and angle changes, achieved by altering the punch and lower die.

There are various types of press brakes, which can be classified into four categories based on the driving mechanism of the machine: mechanical, pneumatic, hydraulic, and servo-electric.

The mechanical press brake, a commonly used type in the past, transforms circular motion into linear motion through the use of a flywheel.

The pneumatic press brake is powered by air pressure, while the hydraulic press brake converts hydraulic oil and pump force into driving force via a hydraulic device.

The servo-electric press brake, on the other hand, uses the kinetic energy generated by a servo motor to drive the ram.

Pressure applied on the metal plate is measured in tonnage units, with the required tonnage increasing as the thickness of the plate increases.

Pros

The press brake is equipped with a range of punches and dies, allowing it to be used for processing a variety of workpieces and sheet metals.

The press brake excels in producing different types of workpieces in small quantities, such as S-shaped, U-shaped, polygonal, and other shaped products.

Using a press brake tooling storage box can prolong the life of the toolings and lower the cost of production as the toolings are durable and not prone to excessive wear.

Additionally, the press brake has a crowning function and can automatically compensate for any discrepancies in the machine.

When dealing with long workpieces, the press brake can also maintain a consistent angle to keep the bend in a straight line, ensuring the accuracy of the final product.

Cons

The press brake has a limited tonnage range and can only bend plates within a certain thickness.

Plates that are too thick cannot be bent, with a typical maximum plate thickness of 50mm.

After cutting the plate, there may be an oxide layer present, which can cause cracks or fractures during bending.

If the bent plate does not match the tooling, creases may form during the bending process, requiring rework or resulting in waste.

If the press brake operates at a stroke speed that is too fast, the operator may not be able to position the plate correctly, leading to defects in the final product or even scrap.

It is worth noting that the press brake is limited to bending and cannot perform punching or other processes, serving as a preliminary step in the manufacturing process.

The press brake also requires at least one operator and has a relatively slow bending process, leading to increased time and labor costs in the long run.

Additionally, the tolerance for the press brake is not as strict, leading to lower precision in the final product compared to other metal manufacturing machines.

What Is Punch Press?

Punching is a metal forming process, and the punch press is a machine that processes metal plates using the punching process.

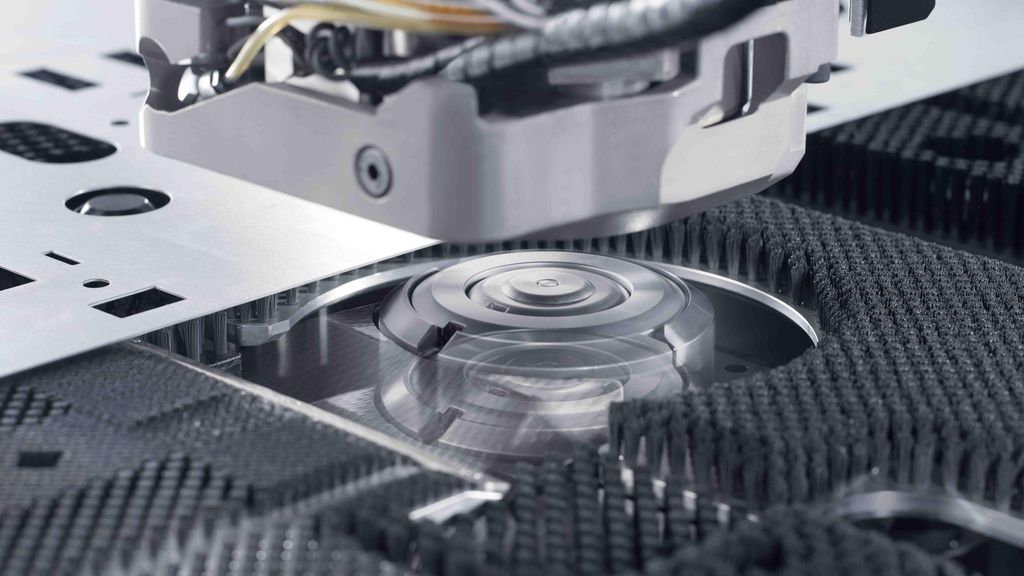

The important parts of the punch press include a frame, which can be C-shaped or door-shaped, a turret, toolings, and a hydraulic cylinder.

The punch press is utilized to punch or cut holes in the workpiece by driving the punch, with manual and automatic punches being the most common types.

When punching, the upper and lower dies are driven by the ram to cut and punch the metal plate, with the shape and size of the die influencing the shape and size of the workpiece.

Materials that can be processed by the punch press include cold-rolled steel, aluminum, copper, and spring steel.

There are different types of punch presses, including CNC punch press, pneumatic punch press, hydraulic punch press, and mechanical punch press.

The workpieces produced using a punch press are usually used for electrical appliances, sockets, kitchen supplies, and other products.

Pros

- The punch press can create precise round or square holes by adjusting the die or stroke.

- In addition to punching, the punch press can also be used for cutting, which makes it a good alternative to laser cutting machines.

- The machine is stable and accurate, and is equipped with emergency brakes and light curtain equipment for added safety.

- The punch press is durable, as its components including the punch and gear are made of high-strength alloy.

- It eliminates the need for a secondary forming operation as it completes the forming in a sequential manner during punching.

Cons

- The punch press generates loud noise during operation, which can be harmful to the operator.

- The punch press is expensive, consumes a lot of energy, and is time-consuming, and cannot process thick plates.

- Customized toolings are costly, as the punch press typically comes with standard size and shape toolings.

- The toolings wear over time and need to be replaced regularly.

- The punch press leaves a significant gap between parts during punching, leading to waste of space.

What’s the Difference Between Press Brake and Punch Press?

What’s the Difference Between Press Brake and Punch Press?

The punch press is primarily used for metal punching, marking, cutting, slitting, rolling, deburring, forming, tapping, and countersinking operations.

Its versatility arises from the various types of punching tooling that it can accommodate.

A punch press has the capability to carry out overall shearing and punching, and some models even come equipped with laser cutting and material feeding devices.

The shape of the workpiece is determined by the shape of the punch tooling, some of which can rotate.

After the metal sheet is processed by the punch press, there will be no burr and the shape of the workpiece will remain intact.

However, the punch press is not suitable for turning the workpiece, which makes it not ideal for working on pieces with positive and negative bending.

The maximum bending angle of the punch press is typically around 90 degrees, and its tonnage range is relatively small, allowing for the processing of only thin plates.

Additionally, the punch press requires a certain clearance during processing, limiting the length of the workpiece that can be processed.

The press brake, on the other hand, is mainly used for bending metal plates, and its function is relatively singular.

The press brake consists of two groups of matching toolings, with the upper die pressing the plate into the lower die under pressure.

The toolings of the press brake can be disassembled, but they cannot be moved during the bending process.

The backgauge of the press brake has multiple axes, which enables accurate positioning of the plate.

The bending angle of the press brake is dependent on the toolings and backgauge, and its bending angle range is much larger than that of the punch press.

The tonnage range of the press brake is substantial, ranging from 40T to 1000T, allowing for the processing of thick plates.

The length of the sheet that can be processed by the press brake is limited by the length of the workbench.

Conclusion

Different sheet metal manufacturing machines are appropriate for producing different parts.

By understanding the features and differences between press brakes and punch presses, you can make an informed decision.

Consider factors such as efficiency, cost, ease of operation, and maintenance when selecting a machine.

Before making a choice, it is important to familiarize yourself with a company's offerings and services.

ADH offers a wide range of machines for sheet metal manufacturing, including press brakes, shearing machines, and laser cutting machines.

Explore our product pages for press brakes, panel benders, and other products, or contact our sales manager for further information.

FAQs About Press Brake and Punch Press

Which one is better the press brake or the punch press?

While both the press brake and punch press are essential machines in the sheet metal industry, they serve different purposes.

The choice between the two will depend on your processing requirements.

If you need to produce a workpiece with numerous holes, a punch press would be the ideal choice.

For bending plates or making shapes such as boxes or pipes, a press brake would be more suitable.

While the punch press is a more versatile machine, the press brake is still an indispensable tool for metal processing.

What is the difference between punching and stamping?

There is often confusion between metal punching and metal stamping. Punch press uses a punch and a die to punch or shear metal plates.

The punch passes through the metal plate while the die protects the metal from damage.

Stamping involves processing the metal plate to achieve the desired profile and requires coordination with other processes.

If you need to produce a specific shape on the workpiece, punching would be the preferred process.

For full workpiece processing, stamping would be the better option.

Punching is ideal for producing prototypes while stamping is better suited for mass production.