An Overview of Press Brake

Press brake is used for bending metal plates to produce profiles with different angles and shapes, which can be used for secondary processing in industries such as construction, aviation, automobile, metallurgy, and chemicals.

There are several types of press brakes, including mechanical, hydraulic, pneumatic, and servo-electric.

The ram of the press brake moves the punch to press the workpiece into the lower die, allowing for repeated bending.

In a CNC press brake, the back gauge and controller accurately control the bending angle and stroke.

An Overview of Shearing Machine

Definition of Shearing Machine

Shearing is a metal fabrication process used to cut materials, performed by a shearing machine.

The shearing machine is equipped with blades or rotating discs and can be used to cut metal plates, pipes, bars, and rods, as well as other materials such as paper, fabric, and plastic.

The process starts with fixing the metal plate in place using the squaring arm between the blades and molds.

The upper blade holds the workpiece and moves it downward through the stationary blade for cutting.

Straight blade shearing is typically used to cut rectangular and square sheets and strips.

The upper and lower blades of the shearing machine are not perfectly parallel, with the upper blade angled at a range of 0.5° to 2.5°.

A clearance between the blades is necessary, the size of which is determined based on the thickness of the material being cut.

This clearance affects the smoothness of the cut surface and if the shear stress is excessive, can lead to material fracture.

Types of Shearing Machines

The shearing machine can be categorized into several types based on different classification standards.

These include guillotine shearing machines, bench shearing machines, swing beam shearing machines, hydraulic shearing machines, mechanical shearing machines, and power shears.

The mechanical shearing machine offers high strokes per minute but generates excessive noise.

Furthermore, it lacks the ability to adjust blade clearance and can't handle heavy metal plates, so it is not commonly used.

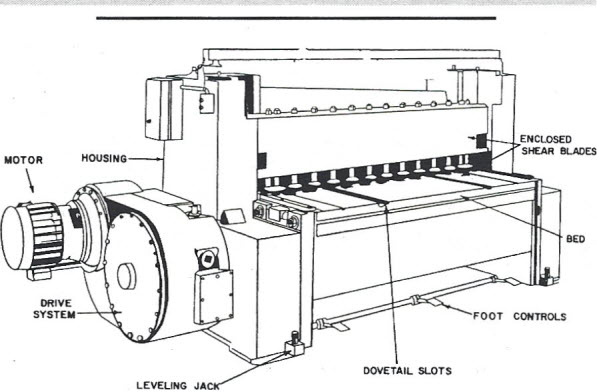

The hydraulic shearing machine operates by using a hydraulic cylinder to drive the ram and upper blade for cutting the plate.

It has a strong load capacity and can perform a long shearing stroke.

The guillotine shearing machine can be either mechanically or hydraulically driven, and it boasts high speed and low cost.

However, it leaves burrs on the cutting surface of the workpiece, making it suitable for mass production.

The bench shearing machine offers multiple functions, including the ability to cut 90-degree angles, round and square steel bars, and T-shaped sections.

It boasts high cutting efficiency and a clean cutting surface without burrs.

Power shears, including electric and pneumatic shears, are ideal for cutting large metal plates with straight lines or large radius curves.

They are flexible, efficient, and precise, and result in a high-quality, burr-free cutting surface.

Advantages and Disadvantages of Press Brake vs Shearing Machine

Advantages of Press Brake

- CNC Press Brakes are designed to improve the efficiency of batch production through repeated bending.

- They are capable of performing complex bending through a range of punches and dies, allowing for the production of precise tools.

- In addition, CNC Press Brakes can be used for edging and the manufacture of various boxes, panels, and other components.

- The angle of the bend can be adjusted, and the final profile can be achieved through multiple bending strokes

Disadvantages of Press Brake

- The process of complex bending in a press brake demands a high level of analytical and decision-making skills from the operator.

- The tonnage capacity of the press brake can be challenging to control, leading to the risk of overloading.

- The transportation of large workpieces can also pose a problem, as it requires specialized transportation equipment.

- Additionally, the center position of the ram and the workbench can cause the workpiece to protrude.

Advantages of Shearing Machine

- The cutting process of shearing is fast, taking only a few seconds to complete.

- t can cut workpieces of different diameters and is ideal for high-efficiency batch production with low cost.

- The straight-cutting process leaves no debris or waste and can be used to cut various metals including stainless steel, iron, copper, and aluminum.

- Shearing does not generate heat, making it ideal for materials that burn or melt easily.

- It's also an efficient method for cutting workpieces with small lengths and simple shapes in large quantities in a short period.

Disadvantages of Shearing Machine

- Shearing may not be suitable for cutting hard metals, such as tungsten, as the workpiece is likely to break and the blades may become damaged.

- Additionally, the process may result in small amounts of burr and end deformation, making it unsuitable for applications that require a clean end face.

- Factors such as the distance between the blades, the gap clearance, and the stability of the workpiece can affect the degree of deformation and burr formation.

- In conclusion, shearing may not be ideal for small-batch production due to these limitations.

Press Brake vs Shear: What Are Their Differences?

Application

The shearing machine and press brake are used for metal processing in the sheet metal industry.

The profiles produced by shears and press brakes can be used in construction, machinery, aviation, shipbuilding, automobile, electric power and other industries.

Only the press brake can make profiles of various angles and shapes by bending.

The plate shears are mainly used to cut metal plates, rods, bars, etc. The processed profiles are mainly simple profiles such as sheets and strips.

Structure

The structure of the press brake mainly includes a frame, a workbench, ram, a power device and upper and lower dies.

The structure of the shearing machine mainly includes the frame, shear table, squaring arm, power device and upper and lower blades.

The upper die of the press brake generally has a right angle, acute angle and obtuse angle punches, as well as gooseneck punches.

The lower die generally has V-shaped and U-shaped, single die and double die, while the die of the shear is not a knife, but a square blade.

Working Principle

Working principle of the press brake

The process of bending begins by placing the workpiece between the upper and lower die.

The press brake then uses a power device to drive the ram and the upper die, pressing the workpiece into the lower die.

There are several types of press brakes, including mechanical, hydraulic, pneumatic, and servo-electric.

Working principle of shearing

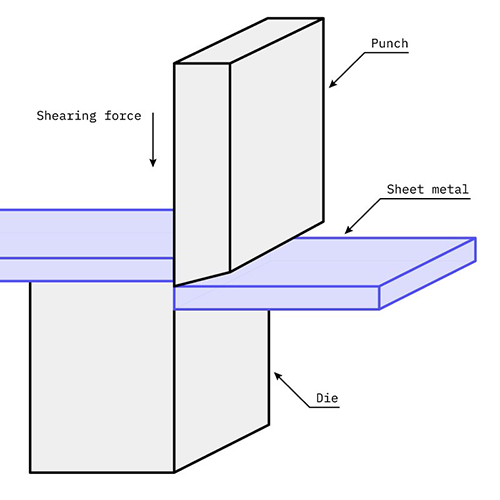

Shearing is the process of separating metal plates by using a strong linear cutting force.

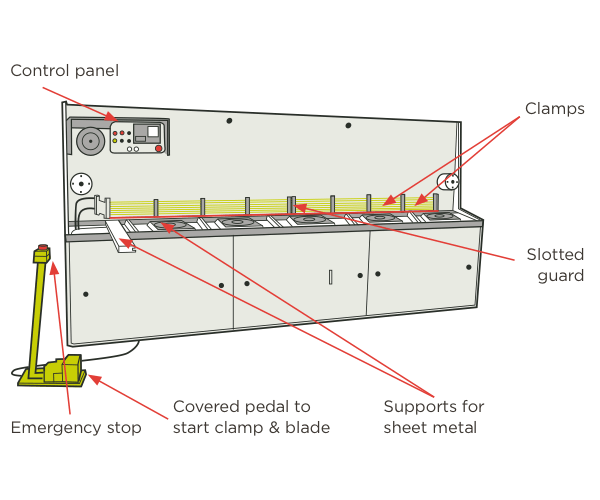

The shearing machine typically includes a shear table with squaring arms, upper and lower blades, stoppers, guide rails, and back gauges that help fix the plates.

To perform the shearing process, a gap is required between the upper and lower blades, with the workpiece placed between them.

The upper blade then moves downward, quickly cutting the metal plate.

The lower blade remains stationary during the process.

Typically, the upper and lower blades have a deviation from the plate thickness of around 5%.

The upper blade cuts from one end to the other, reducing the shearing force.

It's important to note that the shearing blade is not a knife, but a square die.

Low-alloy steel blades are used for low-yield materials, while high-alloy steel blades are used for high-yield materials.

FAQs

Which is better? press brake or shearing machine

Both the press brake and the shearing machine are commonly used in the sheet metal industry, but they serve different purposes.

While shearing machines are used for cutting sheets, press brakes are used for bending metal sheets and creating complex parts.

It is difficult to determine which machine is better, as it ultimately depends on your production demand and budget.

Press brakes have more complex functions, but shearing machines are more suitable for mass-producing simple parts.

Can you shear with a press brake?

No, a press brake is designed for metal bending, not metal shearing.

Other metal cutting machines include shearing machines, presses, flame-cutting, fiber laser cutting, plasma cutting, and high-pressure water cutting.

Some press brakes may have a limited stamping capacity after changing the punches, but they are not designed for shearing.

Conclusion

If your production requires strips and sheets, then a press brake is the right choice.

On the other hand, if you are producing boxes, pans, lids, and similar items, then a shearing machine is the ideal option.

Remember, the shearing machine is used for cutting, and the press brake is used for bending.

You can select the appropriate machine based on your production and maintenance needs.

Our press brakes and shearing machines have high-cost performance, multi-functionality, and low maintenance costs.

If you need assistance in choosing the right machine, our product experts are available to compare the advantages, disadvantages, and features of different machines.