What Is Metal Manufacturing?

Metal manufacturing involves the transformation of metal into parts using a series of machines and tools. The process involves cutting, bending, and welding the metal.

Once the parts are designed, they are processed using various machines such as a laser cutting machine, CNC press brake, turret press, and welding machine.

These machines are suitable for small-batch parts manufacturing.

In the manufacturing industry, metal forming methods mainly include stamping, roll forming, and press braking.

This article aims to introduce the differences, advantages, and disadvantages of these metal-forming processes.

It will also highlight the factors to consider when selecting metal-forming methods.

The metal manufacturing process selected will vary depending on the type of products needed.

The following is a detailed introduction to different metal manufacturing methods.

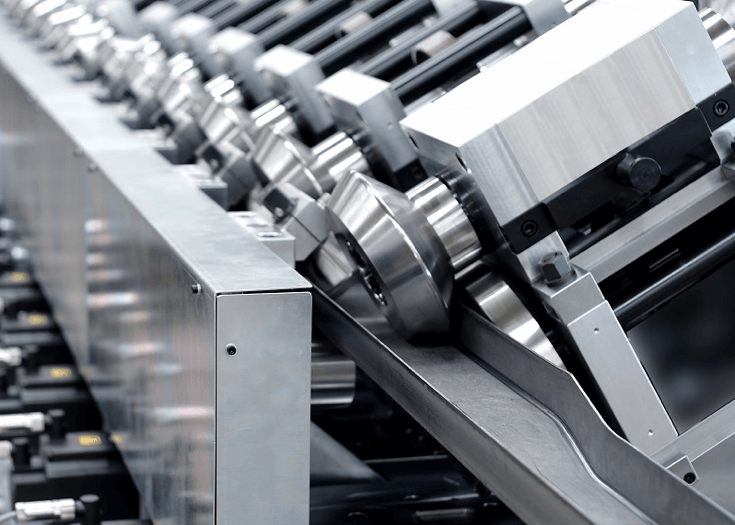

What Is Roll Forming?

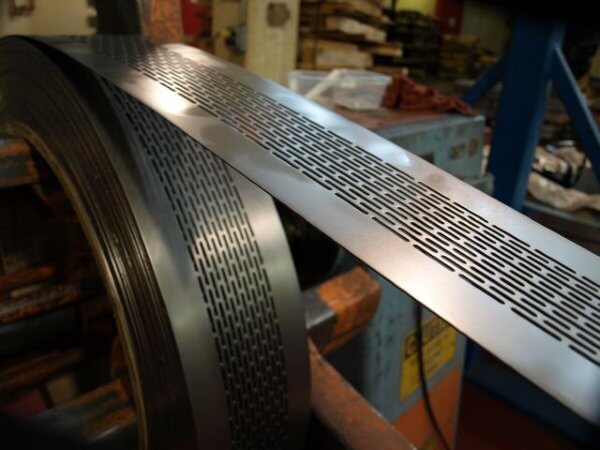

Roll forming is a metal forming process where metal sheets or rolls are bent into longitudinal and uniform profiles with the assistance of specialized tools.

The raw materials used for roll forming are metal flat plates or metal rolls.

Unlike other metal forming processes, roll forming is a cold forming process that doesn't require high-temperature equipment to heat the metal.

The bending radius in roll forming is determined by the material characteristics of the metal plate and can complete 180-degree bending.

This process provides strict tolerances for complex profiles and can integrate welding, laser cutting, and other secondary processing into a production line.

The roll forming machine is available in two types: a single task roll forming machine that gradually bends each specific section by connecting the profile with the spindle, and a standard roll forming machine that is easy to operate, with the operator being able to remove the spindle easily.

Besides these two types, there are parallel machines that can be equipped with a variety of rolling tools.

Advantages of Roll Forming

Roll forming technology is ideal for mass manufacturing and complex parts manufacturing due to its gradual bending process, which can produce strict tolerances.

Even complex profiles produced through roll forming will be highly standard and accurate.

Roll forming is suitable for mass production, as the length of the material is not limited by the machine.

The strength of the material can be improved after spring back by coiling the metal plates and feeding them into the machine.

Roll forming machines can produce complex cross-sections and bends, with strict and repeatable tolerances.

The size of the produced parts is very accurate, with uniform and glossy surfaces.

Roll forming is capable of handling high-strength metals without breaking.

There is no limit to the length of parts formed by roll forming, and the maintenance cost of rolling machine tools is low.

Roll forming produces less waste and uses fewer materials to produce stronger parts.

Disadvantages of Roll Forming

Roll forming is more suited for the mass production of complex parts, and the cost of small-batch production using roll forming can be high.

The tooling used in roll forming is complex and expensive, and changing the tooling can add to the cost.

Roll forming may cause the port of the part to expand outward, which can be a disadvantage in certain applications.

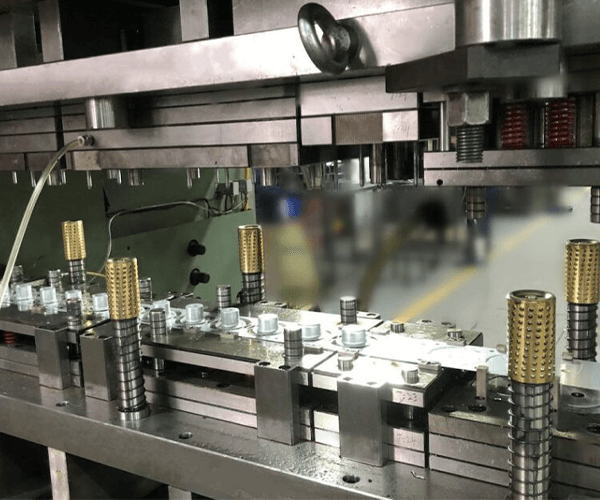

What Is Metal Stamping?

Metal stamping is the forming process of metal using a large tonnage stamping machine.

The process involves stamping, bending, punching, flanging, and pressing.

Custom tools and machines are used to shape the workpiece into the desired pattern.

Stamping is suitable for mass production of parts, with simple parts requiring only one stroke, while complex parts may require multiple strokes.

Advantages of Stamping

Stamping operations are simple, easy to use, and cost-effective.

The stamping process is fast, and the requirements for operators are not high.

Disadvantages of Stamping

If the workpiece produced by the stamping machine is long, it may leave tool scratches.

After stamping, the workpiece may sustain some damage.

Stamping only deforms the metal through the tools, which can be a disadvantage for certain applications.

When a workpiece requires different lengths, it needs different stamping dies, which can increase production costs.

Therefore, stamping is more suitable for small batch production.

What Is Press Braking?

Pressure braking completes metal forming by bending the metal sheet with upper and lower dies.

The process of pressure braking is the process of repeatedly driving the mold bending through the driving system.

The upper die of press braking has different angles, and the lower die is generally V-shaped and U-shaped.

There are many factors that affect bending, such as tensile strength of materials, precision, and strength of toolings, tonnage, bending radius, stroke, back gauge distance, speed, etc.

These factors will affect the spring back of the sheet metal and the accuracy of the final profile.

Advantages of Press Braking

The efficiency of press braking is very high, but generally, it can only deal with small and short workpieces.

The operation and setting of the press brake are more convenient.

It only needs to replace the top dies or lower dies for different bending shapes and angles.

Compared with roll forming and stamping, press braking has lower costs and higher efficiency.

Disadvantages of Press Braking

The tolerance of press braking is not as strict as that of roll forming, so the accuracy of the final profile may not be high enough.

The appearance and accuracy of the profile rely more on the accuracy and manufacturing method of the material used.

Press braking is suitable for small workpiece manufacturing in small batches.

The length of the press brake is limited, and the press brake cannot bend the metal beyond its body.

In addition, press braking requires repeated adjustments, involving more steps than roll forming.

Press braking is only the first step in manufacturing parts and cannot create products with complex functions.

The operation process of press braking also has higher requirements for operators.

The operation process involves different bending methods, such as air bending, bottom bending, and coining.

How to Choose the Appropriate Manufacturing Method?

When choosing different manufacturing methods, the following factors can be considered:

Size of Workpieces

Workpieces of different sizes and volumes require different manufacturing costs.

The manufacturing cost of small workpieces is lower than that of large workpieces.

In the manufacturing process of workpieces, different manufacturing technologies can be used.

Shearing machines and laser cutting machines can be used to cut sheet metals, which can then be processed with a stamping machine or bent with a press brake.

Material Types

Different manufacturing processes are suitable for different materials.

The ductility and tensile strength of materials vary, which influences the suitable manufacturing process.

Press braking and roll forming are suitable for materials with low strength.

High-strength materials have poor ductility, making it difficult to bend and roll form.

Using unsuitable materials will generate a significant amount of waste and damage the tooling.

Workpiece Design

Certain workpiece designs, such as holes and embossing, are more suitable for stamping.

The cutting edge of laser cutting will be smoother, whereas the edge of stamping will have many cracks.

The shape and complexity of the workpiece also affect the choice of the metal forming method.

Roll forming can form complex linear shapes in a single pass, while bending requires multiple passes.

Cost

Ultimately, all choices aim to reduce costs while maintaining quality.

The labor cost of stamping automation is lower than that of manual bending.

There is little difference in tooling cost between roll forming and press braking.

Roll forming can save costs for the mass production of large workpieces.

Press braking is more suitable for small workpieces and small-batch manufacturing.

Conclusion

Press braking, stamping, and roll forming are all effective metal processing processes in the sheet metal industry, each with its own set of advantages and disadvantages.

Stamping machines, roll forming machines, and press brakes are commonly used in the sheet metal industry.

ADH is a professional manufacturer of press brakes, laser cutting machines, and shearing machines, with years of experience in the industry.

Our range of press brakes includes CNC press brakes, NC press brakes, and tandem press brakes.

For detailed information about our press brake products, please visit our website or contact our sales team.