| Configuration Parameter | PB1400P | PB2000P | PB2500P |

|---|---|---|---|

| Fastest bend speed | 0.2 sec/bend | 0.2 sec/bend | 0.2s/bend |

| Maximum bend width | 1400mm | 2000mm | 2500mm |

| Bend height | 170mm | 170mm | 170mm |

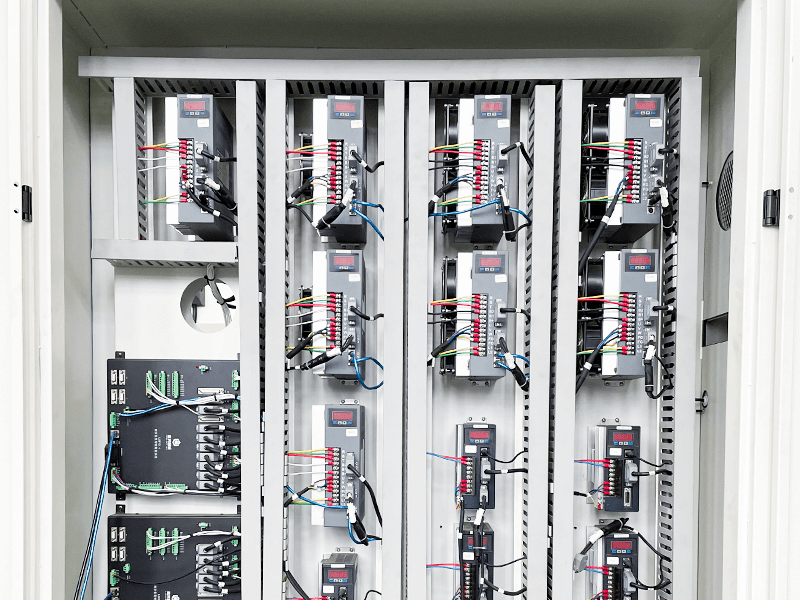

| Rated voltage | 380V | 380V | 380V |

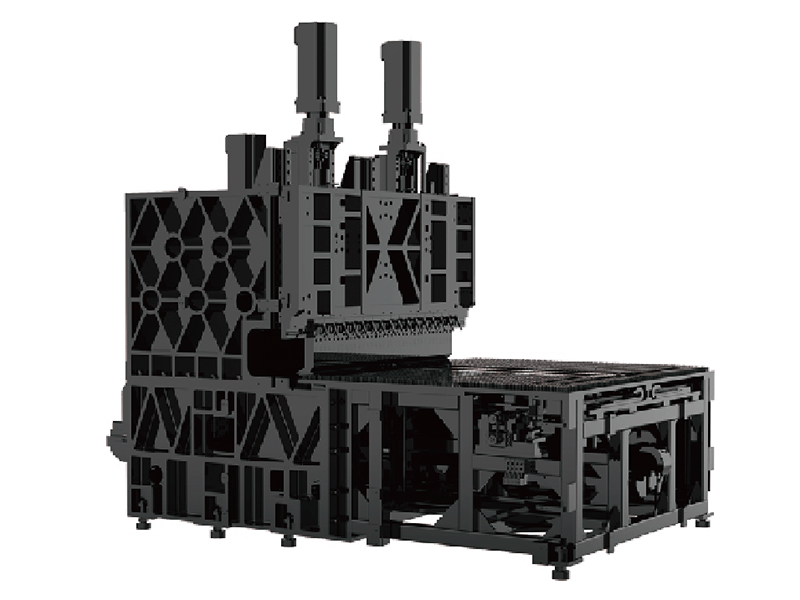

| Total motor power | 38KW | 77KW | 77KW |

| Average power | About 1.8Kw | About 2.5Kw | About 2.8Kw |

| Noise | About 50dB | About 50dB | About 50dB |

| Overall dimensions | 440*190*290cm | 510*265*330cm | 565*300*340cm |

| Total weight | About 12t | About 16t | About 19t |

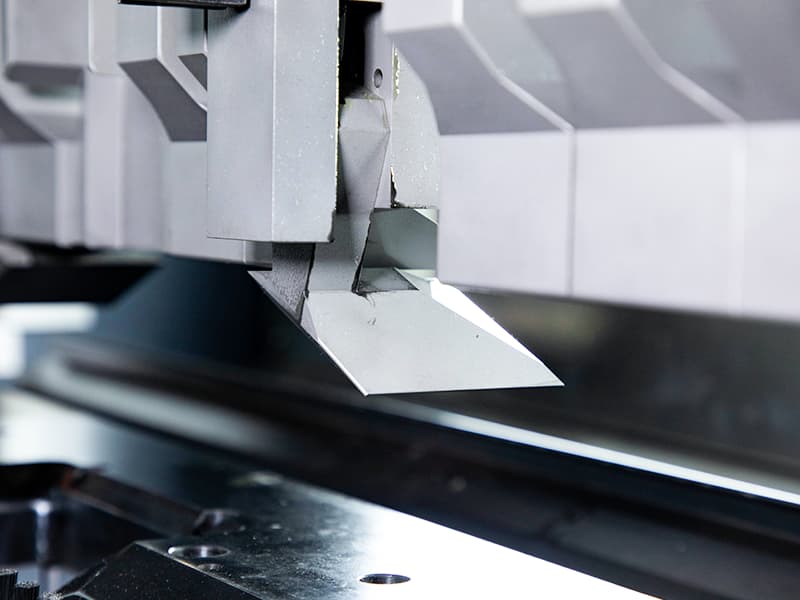

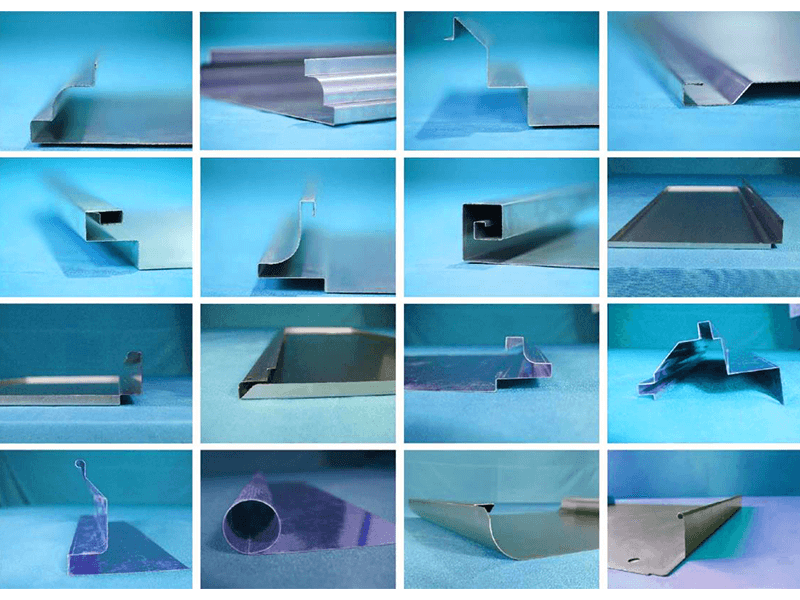

| Maximum bend thickness (customized) | UST 515N/mm² 304 Stainless Steel 1.2mm UST 410N/mm² Cold Plate 1.5mm UST 515N/mm² Aluminum Plate 2.0mm | UST 515N/mm² 304 Stainless Steel 1.2mm UST 410N/mm² Cold Plate 1.5mm UST 515N/mm² Aluminum Plate 2.0mm | UST 515N/mm² 304 Stainless Steel 1.2mm UST 410N/mm² Cold Plate 1.5mm UST 515N/mm² Aluminum Plate 2.0mm |

| Minimum material thickness | 0.35mm | 0.35mm | 0.35mm |

| Minimum internal dimension of four-sided forming | 140*190mm | 140*190mm | 140*190mm |

| Minimum internal dimension of four-sided forming | 140mm | 140mm | 140mm |

| Maximum bend size | 1400*1000mm | 2000*1250mm | 2500*1250mm |

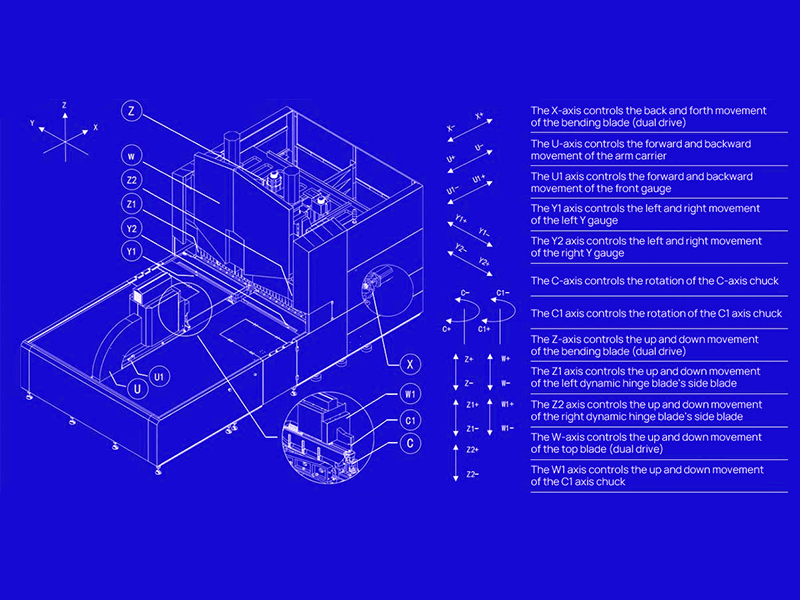

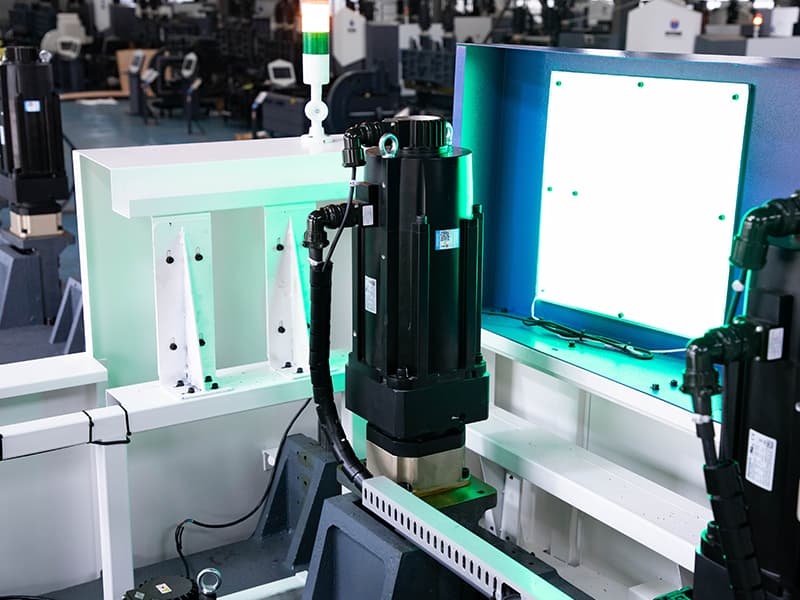

| Number of axes | Standard 13-axis concurrent linkage | Standard 13-axis concurrent linkage | Standard 13-axis concurrent linkage |

| Power hinge knife | Optional | Optional | Optional |