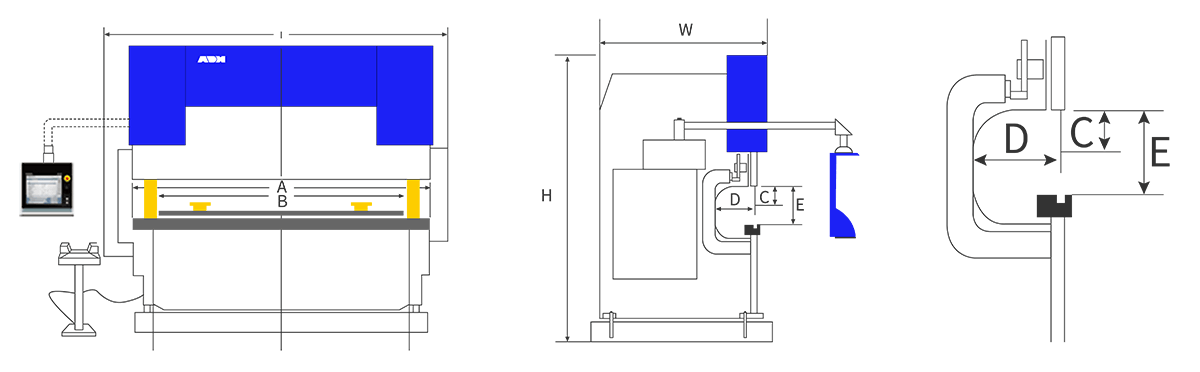

| Model | Bending Force | Bending Length (A) | Approaching Speed | Ram Speed | Return Speed | Column Distance (B) | Throat Depth (D) | Stroke (C) | Open Height (E) | Main Motor | Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | KN | mm | mm/s | mm/s | mm/s | mm | mm | mm | mm | KW | Ton | L×W×H mm |

| 400T/3200 | 4000 | 3200 | 80 | 8 | 80 | 2600 | 500 | 300 | 610 | 30 | 23 | 3800*2700*3500 |

| 400T/4000 | 4000 | 4000 | 80 | 8 | 80 | 3100 | 500 | 300 | 610 | 30 | 30 | 4600*2700*3500 |

| 400T/5000 | 4000 | 5000 | 80 | 8 | 80 | 3800 | 500 | 300 | 610 | 30 | 32 | 5600*2700*3500 |

| 400T/6000 | 4000 | 6000 | 80 | 8 | 80 | 4800 | 500 | 300 | 610 | 30 | 38 | 6600*2700*3500 |

| 500T/4000 | 5000 | 4000 | 80 | 8.5 | 90 | 3100 | 500 | 300 | 610 | 37 | 37 | 4600*2700*3500 |

| 500T/5000 | 5000 | 5000 | 80 | 8.5 | 90 | 3800 | 500 | 300 | 610 | 37 | 42 | 5600*2700*3500 |

| 500T/6000 | 5000 | 6000 | 80 | 8.5 | 90 | 4800 | 500 | 300 | 610 | 37 | 48 | 6600*2700*3600 |

| 600T/4000 | 6000 | 4000 | 80 | 8.5 | 85 | 3100 | 600 | 320 | 650 | 45 | 48 | 4600*3300*3900 |

| 600T/5000 | 6000 | 5000 | 80 | 8.5 | 85 | 3800 | 600 | 320 | 650 | 45 | 52 | 5600*3300*3900 |

| 600T/6000 | 6000 | 6000 | 80 | 8.5 | 85 | 4800 | 600 | 320 | 650 | 45 | 58 | 6600*3300*3900 |

| 600T/7000 | 6000 | 7000 | 80 | 8.5 | 85 | 5600 | 600 | 320 | 650 | 45 | 68 | 7600*3300*3900 |

| 700T/6000 | 7000 | 6000 | 80 | 8.5 | 85 | 4900 | 600 | 320 | 700 | 55 | 78 | 6600*3500*4000 |

| 800T/6000 | 8000 | 6000 | 80 | 8 | 90 | 4600 | 600 | 320 | 800 | 30*2 | 79 | 6600*3500*4000 |

| 800T/7000 | 8000 | 7000 | 80 | 8 | 90 | 5600 | 600 | 320 | 800 | 30*2 | 7600*3500*4200 | |

| 800T/8000 | 8000 | 8000 | 80 | 8 | 90 | 6600 | 600 | 320 | 800 | 30*2 | 8600*3600*4500 | |

| 800T/10000 | 8000 | 10000 | 80 | 8 | 90 | 7800 | 600 | 320 | 800 | 30*2 | 10600*3600*4900 |