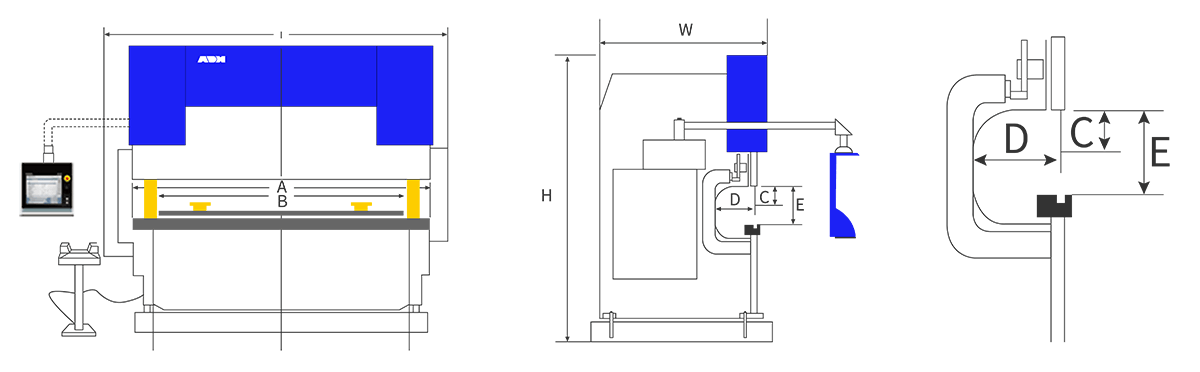

| Model | Bending Force | Bending Length (A) | Aprroaching Speed | Ram Speed | Return Speed | Column Distance (B) | Throat Depth (D) | Stroke (C) | Daylight (E) | Main Motor | Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | KN | mm | mm/s | mm/s | mm/s | mm | mm | mm | mm | KW | Ton | L*W*H mm |

| 50T/1300 | 500 | 1300 | 220 | 15.5 | 200 | 1120 | 300 | 150 | 460 | 6 | 4.5 | 1800*1500*2300 |

| 70T/1600 | 700 | 1600 | 220 | 15.5 | 200 | 1300 | 300 | 150 | 460 | 6 | 5.3 | 2300*1600*2500 |

| 70T/2500 | 700 | 2500 | 220 | 15.5 | 200 | 2050 | 300 | 150 | 460 | 6 | 6 | 3100*1600*2500 |

| 80T/2500 | 800 | 2500 | 220 | 15 | 185 | 2050 | 300 | 150 | 460 | 8.7 | 6.5 | 3100*1600*2600 |

| 110T/2500 | 1100 | 2500 | 220 | 15 | 195 | 2050 | 400 | 200 | 480 | 10.8 | 8.5 | 3100*1800*2600 |

| 110T/3200 | 1100 | 3200 | 220 | 15 | 195 | 2700 | 400 | 200 | 480 | 10.8 | 8.5 | 3800*1800*2600 |

| 110T/4000 | 1100 | 4000 | 220 | 15 | 195 | 3100 | 400 | 200 | 480 | 10.8 | 9.5 | 4600*1800*2600 |

| 110T/4100 | 1100 | 4100 | 220 | 15 | 195 | 3600 | 400 | 200 | 480 | 10.8 | 10.0 | 4700*1800*2700 |

| 135T/3200 | 1350 | 3200 | 220 | 12 | 150 | 2700 | 400 | 200 | 480 | 10.8 | 10 | 3800*1800*2700 |

| 135T/4000 | 1350 | 4000 | 220 | 12 | 150 | 3100 | 400 | 200 | 480 | 10.8 | 11 | 4600*1800*2700 |

| 135T/4100 | 1350 | 4100 | 220 | 12 | 150 | 3600 | 400 | 200 | 480 | 10.8 | 11 | 4700*1800*2700 |

| 170T/3200 | 1700 | 3200 | 160 | 12 | 122 | 2700 | 450 | 200 | 480 | 13.2 | 11.8 | 3800*2000*2800 |

| 170T/4000 | 1700 | 4000 | 160 | 12 | 122 | 3100 | 450 | 200 | 480 | 13.2 | 13 | 4600*2000*2800 |

| 170T/4100 | 1700 | 4100 | 160 | 12 | 122 | 3600 | 450 | 200 | 480 | 13.2 | 13 | 4700*2000*2800 |

| 220T/3200 | 2200 | 3200 | 160 | 11.5 | 135 | 2600 | 450 | 200 | 480 | 16.7 | 13 | 3800*2200*2850 |

| 220T/4000 | 2200 | 4000 | 160 | 11.5 | 135 | 3100 | 450 | 200 | 480 | 16.7 | 15 | 4600*2200*2850 |

| 250T/3200 | 2500 | 3200 | 100 | 10.5 | 130 | 2600 | 450 | 250 | 540 | 16.7 | 16.5 | 3500*2000*2900 |

| 250T/4000 | 2500 | 4000 | 100 | 10.5 | 130 | 3100 | 450 | 250 | 540 | 16.7 | 18.8 | 4300*2100*3100 |

| 250T/5000 | 2500 | 5000 | 100 | 10.5 | 130 | 3800 | 450 | 250 | 540 | 16.7 | 23 | 5300*2150*3150 |

| 250T/6000 | 2500 | 6000 | 100 | 10.5 | 130 | 4800 | 450 | 250 | 540 | 16.7 | 25 | 6300*2150*3150 |