What Is A Bending Machine?

A bending machine is a machine used to bend and shape workpieces.

There are many types and functions of bending machines, which can either serve as a press or a bending machine.

Some bending machines can process sheet metal directly without the need for clamping tools, while others require clamping tools to assist with bending.

The metal sheet is secured by the clamping device and remains in place throughout the entire processing process.

The bending machine uses the bending tool to shape the metal plate and create the desired profile.

The body and tools of the bending machine must be made of special materials to ensure that they can withstand the pressure applied during processing without being damaged.

Types of Bending Machine

There are several types of bending machines, including pipe bending machine, sheet metal bending machine, sheet folding machine, hydraulic bending machine, mechanical bending machine, electric servo bending machine, electric pipe bending machine, and cutting and punching machine, among others.

Pipe bending machine

What Is A Pipe Bender

Pipe bender is a machine that is used for bending metal pipes and profiles into various shapes.

The profiles are usually square or rectangular in shape and are made of thick metal.

Bending is a stretching process that generates friction between the pipes and the bending tools.

To extend the life of the tools and the pipe bender, drawing oil can be used to reduce the resistance between the pipe and the tools.

Pipe bending and manufacturing equipment are utilized for performing various operations such as bending, swaging, flaring, and crimping.

The pipe bender can bend various metal materials such as stainless steel, iron, copper, aluminum, titanium, and carbon steel.

These materials have a high degree of ductility and small elastic deformation, which makes them suitable for supporting the structure of the bent section.

The pipes processed by the pipe bender have a smooth and uniform curve, with no external collapses or internal folds.

The pipe is a hollow container that is widely used for transporting gas, solids, and fluids in various industrial, medical, and other equipment.

The pipe bender is mainly used for laying pipes in construction projects, such as in buildings, highways, railways, bridges, and more.

Structure of Pipe Bending Machine

The pipe bending machine consists of the clamp die, bend die, pressure die, wiper die, and mandrel.

The dies of the pipe bender are typically made of hardened steel to withstand the bending process and prevent damage.

However, tools like wiper dies are made of softer materials such as aluminum or brass to prevent damage to the pipes being bent.

Bend die

The bend dies, also known as the radius die, is a crucial part of the rotary drawing process.

It holds the pipe in place and bends it during the drawing process.

The shape of the bend die determines the inner radius of the bent pipe.

Clamp Die

The clamp die is used in conjunction with the bend die to hold the pipe in place and prevent it from slipping during the bending process.

Wiper die

The wiper die smoothens the surface of the bent pipe and prevents the inner radius from collapsing and the outer surface from being damaged.

Made of softer materials such as aluminum or brass, the wiper die helps prevent damage to the pipes.

Pressure die

The pressure die is used to apply pressure to the pipe during the bending process, ensuring a consistent and accurate curved profile.

Mandrel

Mandrels are used to support the bending of small-radius pipes, thin tubes, and hard materials.

They work with the wiper die to prevent the pipes from wrinkling on the inside and collapsing on the outside during the bending process.

How Does A Pipe Bending Machine Work?

A pipe-bending machine works by applying pressure to bend pipes. The source of this pressure can be hydraulic, electric servo, pneumatic, or manual.

The pipe is first clamped in place by the clamping block and forming tools and adjusted to the shape of the die.

Then, as one end of the pipe rotates and rolls around the die, it is fixed in place.

There are also other methods of processing pipes through rollers to form profiles.

When bending pipes, a mandrel is often inserted inside to prevent the inside of the pipe from collapsing and wrinkling.

The scraping die of the pipe bender helps maintain tension on the pipe and prevent damage when force is applied.

The wiper dies, typically made of aluminum or brass, help prevent scratches on the raw material.

There are several methods of bending pipes with a pipe bending machine, including press bending, rotary draw bending, compression bending, roll bending, mandrel tube bending, wiper die bending, heat induction bending, sand packing and hot slab forming, and ram bending.

Metal Sheet Bending Machine

A sheet metal bending machine is used for shaping sheet metal into specific profiles.

The metal sheet is positioned on the lower die of the workbench and then pressed by punches to complete the bending process.

The movement of the slider, which is driven by the power system, results in the downward movement of the punch.

This type of machine can bend metal sheets or pipes to any angle. If the machine is specifically designed for bending pipes, it is referred to as a pipe-bending machine.

The sheet metal bending machine is suitable for processing larger workpieces that cannot be handled by other machines.

The workpiece is securely held in place by the clamping shaft, which is driven by the power system.

After the workpiece is fixed, the folding arm of the swing beam swings in an arc, bending the flange to the desired angle.

Plate Rolling Machine

A pyramid-type mechanical plate bending machine is utilized for bending and forming metal plates.

The bottom roller is powered by a motor and gear and can rotate.

The upper roller's required bending radius can be adjusted manually up and down.

The steel plate bending machine features a double-sided pre-clamping device, with a unique structure that enables the two bottom rollers to pre-clamp the workpiece.

The upper roller is fixed and pre-clamped by the two lower rollers through hydraulic cylinders.

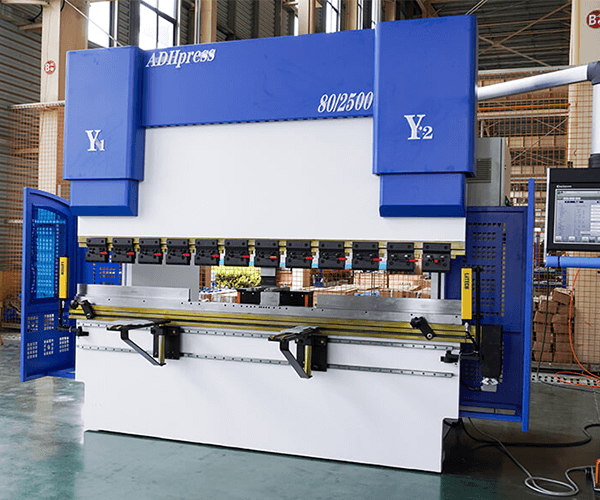

Press Brake

Press brake is a type of bending machine that is used for bending metal plates.

There are various types of press brakes that are powered by different systems.

The press brake has at least three shafts on the rear gauge, which allows for control over the accuracy, speed, and stroke of the machine.

It is easy to operate and can process workpieces in bulk.

Conclusion

There are several types of bending machines available, including pipe bending machines, metal plate bending machines, and plate rolling machines. Each type of machine has its own advantages and disadvantages, and the best machine for the job can be chosen based on the production requirements.

Factors such as the required production process, output, and budget should be considered when selecting a bending machine.

Our company offers a comprehensive range of metal processing solutions, including shearing machines, laser cutting machines, press brakes, slotting machines, etc.

If you need help selecting the right metal processing solution, please do not hesitate to contact us, and one of our sales representatives will be happy to assist you.