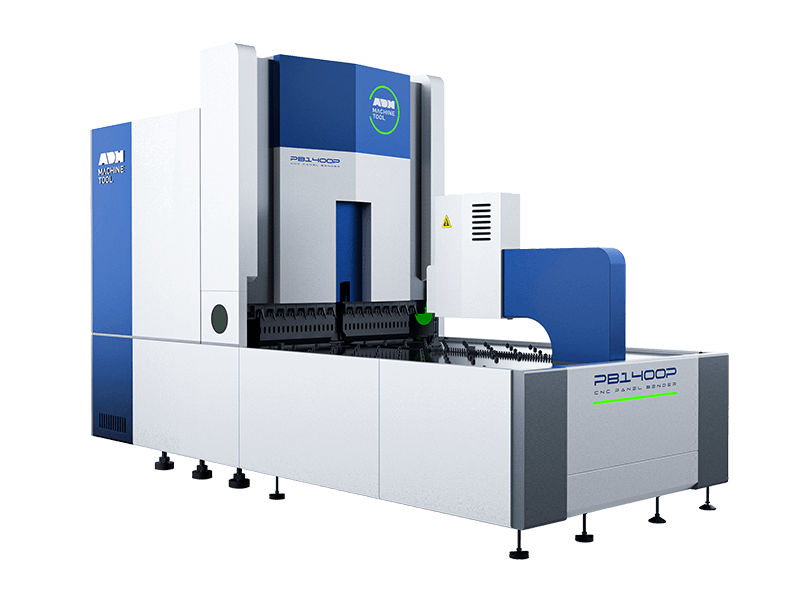

Our specialized manufacturing capabilities are powered by over 200 state-of-the-art key processing equipment, including CNC five axis linkage machining centers, CNC gantry machining centers, a 16-meter heat treatment furnace, shot blasting machines, and super-sized CNC boring and milling machines.