Operating the press brake requires mastering different skills, and the requirements for the press brake operator are also very high.

They should not only be able to use machines but also understand mathematics, read design drawings and learn machine programming, and more.

This article will detail the work content, work requirements, and work prospects of the press brake operator.

What Does a Press Brake Operator Do?

A Press Brake is a machine used for bending sheet metal and is widely used in the manufacturing industry.

It can be said that the press brake is the machine that makes the machine.

The work of a press brake operator is mainly to operate the machine to bend, shape, and cut various metal materials.

They may also need to use the shearing machine and laser cutting machine to cut sheet metal.

Press brake operators need to check the workpiece design drawing and then use the controller to set the parameters for bending.

During the process of forming the metal plate, they must adjust the sheet metal as required.

Finally, the press brake operator needs to check whether the profile is defective.

After the work is completed, they need to clean the work area.

At the same time, press brake operators also need to regularly check the machine parts and eliminate any faults in the machine.

Regular quality inspection can ensure the normal operation of the press brake.

Operating a press brake requires mastering different skills, and the requirements for the press brake operator are also very high.

They should not only be able to use the machine but also understand mathematics, read design drawings, and learn machine programming, among other things.

This article detailed the work content, work requirements, and work prospects of the press brake operator.

Duties and Responsibilities

- Operate the press brake to bend the metal plate according to the workpiece blueprint and parameters.

- Prepare raw materials according to the production or order plan to ensure that the materials are free from defects and sufficient in quantity.

- Pay attention to the selection of the most suitable sheet metal type and size to avoid material waste and reduce cost.

- Prepare the equipment according to the product specifications to ensure the stable performance of the press brake.

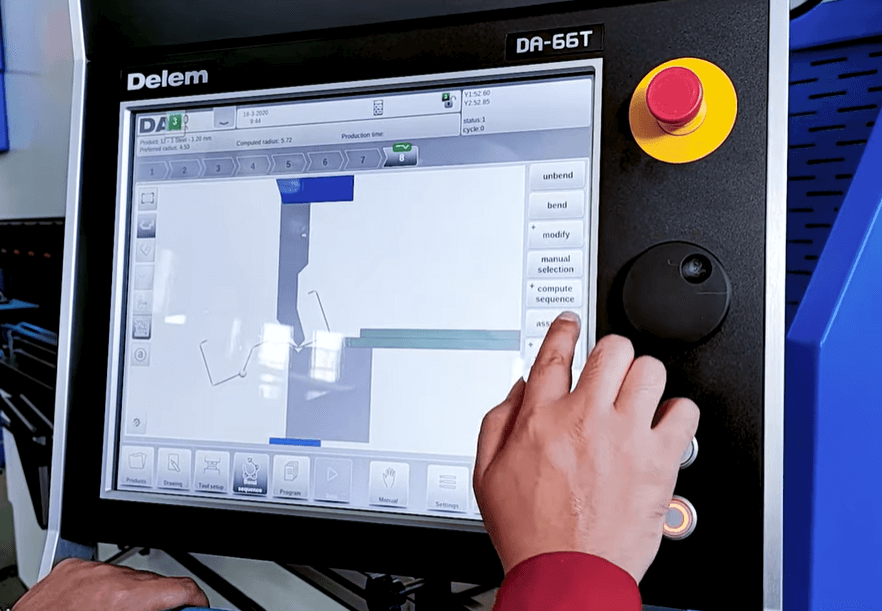

- Operate the CNC controller of the bending machine, set parameters according to the drawing, and be familiar with the programming function of the controller.

- Be able to change toolings, and place or unload metal plates according to the program.

- Operate other equipment, adjust speed, pressure, back gauge, etc.

- After the operation, check whether the profile meets the standard according to the quality inspection standard.

- Clean the working area, check and maintain the equipment, report the equipment failure, repair the machine and ensure the normal operation of the equipment.

- Have a teamwork spirit to ensure the order quantity and quality are completed on time.

Skills and Qualifications

Understanding Tooling and Machines

Press brake operators need to understand the various tools used for the machine, as there are many kinds of press brake toolings.

Choosing the wrong tooling will lead to different bending results.

Press brake operators also need to know different bending methods, such as air bending, bottom bending, and coining.

At the same time, the press brake operator should also know the tonnage limit of the bending machine.

Exceeding the range of bending force will cause damage to the machine.

Press brake operators need to know the type, structure, and working principle of press brake machines very well.

There are different types of bending machines, such as mechanical press brake, hydraulic press brake, electric servo press brake, etc.

Press brake operators should be familiar with the differences, advantages, and disadvantages of different types of press brakes.

Using different press brakes to process different metal plates can improve production efficiency and reduce production costs.

The press brake operator should be able to understand the workpiece drawing and work according to the tolerance of metal materials.

The use of CAD drawings can not only ensure the accuracy of bending workpieces but also improve bending efficiency.

The computer skills of the press brake operator are very important, and it is necessary to proficiently master the computer program editing ability.

Must have certain mathematical calculation abilities, including measuring and calculating dimensions.

To ensure the accuracy of the workpiece, it is necessary to learn to use a caliper in order to perform contour measurements.

Job Qualifications

Most press brake operators are not highly educated, and usually, a high school diploma is enough.

However, this does not mean that the work of the press brake operator is simple. It still requires a high sense of responsibility and attention to detail.

Press brake operators need to have a computer and mathematical knowledge to demonstrate their hands-on ability and analytical skills.

Additionally, they should be able to stand for long periods and have enough physical strength to handle materials.

Generally, press brake operators work in a noisy environment, but they must be able to focus on details.

They need to pay close attention to the operation process and subtle changes in metal plates.

Safety and Training

The press brake operator needs to strictly follow various safety measures to prevent safety accidents from occurring.

At the same time, you also need to participate in some safety training, machine operation training, etc.

The use of safety devices can also reduce risks, including light curtain protection, two-hand control devices, retraction devices, restraint devices, etc.

Salary Expectations

The income of press brake operators is determined by many factors, including relevant experience and technology, working time, company size, and more.

Wages gradually increase from junior press brake workers to skilled workers.

The Future of Press Brake Operators

If press brake operators want to develop in the industry for a long time, they need to keep up-to-date with the latest industry developments at all times.

This way, they can improve their understanding of the industry, enhance their technology skills, and increase their industry knowledge.

Automation is increasingly being used in the sheet metal industry.

To improve production efficiency, enterprises will purchase automated equipment.

Press brake operators should be able to use automation systems, including machine programming and other functions.

Press brake operators should not only have enough skilled experience but also obtain certification from some authoritative institutions.

This way, they will have more competitive advantages in the job hunting process.

How to Become A Press Brake Operator

Firstly, if you want to be an excellent press brake operator, you need to have some basic knowledge, such as mathematics, machinery, computer and other related areas.

You should also understand different metal materials and their characteristics, and learn how to read and understand CAD drawings.

It's important to understand the structure and working principle of the press brake as well.

Once you have acquired this knowledge, the company will provide training to the operators on the operation of the machine.

Press brake operators also need to learn how to make complex workpieces through machine programming.

In short, it's important to constantly learn new technologies and take additional training courses to improve your competitiveness in the industry.