What Is A Punch Press?

Punching is one of the many forming processes used in sheet metal manufacturing.

The process involves pressing a workpiece through a die to change its shape and size, which is determined by the tooling used.

Punching is mainly used for sheet metal processing and can perform actions such as punching, perforating, piercing, and slotting.

Small punches can be operated manually, while larger punches are typically controlled by CNC.

Small punches are suitable for batch production of small, uniform parts.

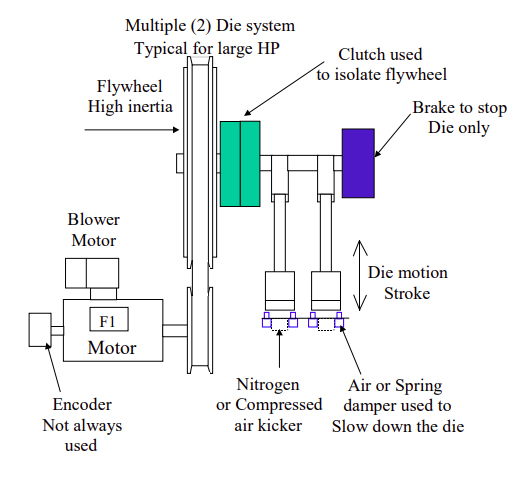

The die size of larger punches is larger and more complex and often has a multi-station turret.

The ram moves the punch up and down, pressing it into the die to perform the punching, perforating, and slotting.

Materials that can be processed by a punch press include cold-rolled steel, aluminum, and bronze.

There are two main types of frames for a punch press: the C-frame, also known as a "door" frame, and the gantry frame.

In a C-frame punch, the hydraulic cylinder is located on the beam and connected to the ram, driving it. The bottom plate of the C-frame uses T-bolts to lock the mold support.

The top and bottom of the punch are connected by a supporting strut and bushing assembly.

In a gantry frame, the oil cylinder is installed in the center of the machine to prevent deflection and deformation.

Parts of Punch Press

Frame and worktable

The frame of the punch press is the external structure that supports the entire machine.

It houses the control and drives systems of the punch press.

The worktable, located below the frame, provides a base for holding the die and workpiece in place.

The size of the worktable determines the maximum size of workpiece that can be processed.

The beam, located at the upper part of the frame, houses the driving device, such as the hydraulic system.

Ram

The ram is the component of the punch press that drives the punch to process the workpiece under pressure.

It is connected to the power system and its up-and-down movement is limited to a fixed stroke and strength.

The stroke, refers to the up and down movement of the ram, and the speed can be adjusted as needed.

Connecting rod

The connecting rod is the part that connects the ram to the crankshaft. It plays a crucial role in transmitting the power from the ram to the punch.

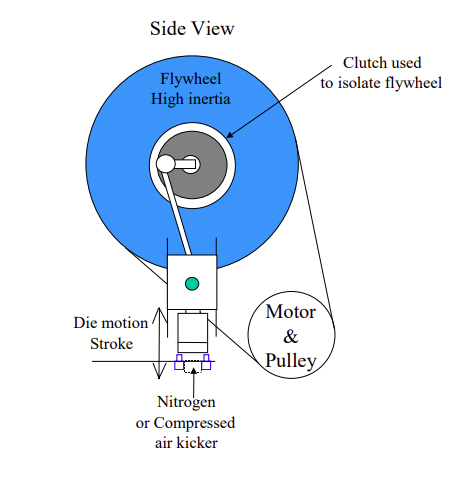

Flywheel

The flywheel is a high-inertia rotating body that is utilized to store energy provided by the drive motor.

It stores energy to maintain the steady speed of the ram.

The flywheel prevents rapid or sudden changes in speed during the punching cycle.

During the non-working part of the punching cycle, the motor recharges the energy released during punching back into the flywheel.

Drive and control mechanism

The crankshaft and eccentric mechanism are powered by the motor to drive the ram.

A control mechanism is utilized to regulate the length and power of the ram's stroke.

Today, with the advancement in automatic control technology, the stroke of the ram can be controlled with greater accuracy.

Punch and die

The punch is a crucial component of the punch press, and it primarily processes the workpiece through the die.

The die is mainly utilized for cutting, punching, piercing, and forming workpieces.

A complete set of tool combinations includes both the upper die and the lower die.

The workpiece is placed on the lower die, and the punch is then pressed into it to create a hole in the workpiece.

Brakes

The brake system of the press machine is crucial for its safe operation.

It disconnects the drive shaft from the flywheel, effectively stopping the machine.

There is also an emergency brake located at the base of the machine that can quickly cut off power.

Features of Punch Press

The components of the press machine, including the crankshaft, gear, and transmission shaft, are hardened and heat-treated after grinding, resulting in high resistance to wear.

This enhances the stability of the machine's performance and the accuracy of its operation.

The frame of the machine is welded using a steel plate and has high rigidity and accuracy.

After undergoing heat treatment, the frame is stable, with uniform load distribution across each component and balanced rigidity.

The press brake is highly sensitive and features a double electromagnetic control valve and an overload protection device.

This ensures that the ram and punch can move and stop accurately and safely.

The automatic feeding system allows for fully automated production, increasing efficiency and reducing cost.

It includes error detection, pre-cutting, and pre-breaking devices and enables quick and safe manual and electrical adjustments to the ram with high accuracy and convenience.

How does A Punch Press work?

The punch press is powered by a motor and its operation is driven by the main motor that drives the flywheel.

The connecting rod and clutch are attached to the crankshaft and the flywheel's motion drives the crankshaft.

This results in the entire drive system causing the ram to move up and down and converting rotary motion into linear motion.

Punches are attached to the ram and the die is installed on the base.

During operation, the punch moves vertically downwards, punching a hole into the material and entering the lower die.

The resulting blank is then used for further processing of the workpiece.

CNC punch presses are controlled by a computer and primarily used to control the punching process.

Conclusion

In this article, we have discussed the definition, composition, characteristics, and working principle of a punch press.

By now, you should have a good understanding of the punch press and its various components.

If you require any additional information about the punch press or other machines, don't hesitate to reach out to us.

FAQs

Application of punch press

A punch press can improve efficiency, save energy, and reduce costs, and doesn't require highly skilled operators.

The punch press can process a variety of workpieces through a range of tooling and techniques, including blanking, stamping, deep drawing, trimming, fine blanking, riveting, and extrusion.

The workpieces produced using a punch press are used in a range of products such as aircraft, ships, computer cases, cabinets, sockets, and more.

What is a mechanical punch press?

Mechanical punch presses are classified into two types: full rotary and partial rotary, based on their braking and clutch systems.

Full rotary punch presses have a crankshaft that rotates fully, which makes it dangerous as it can stop the machine at any moment.

In contrast, partial rotary punch presses are equipped with rotary clutches and brakes, making it possible to safely stop the machine.

What is a hydraulic punch press?

A hydraulic punch press operates by utilizing the force generated by a hydraulic cylinder, which exerts immense pressure on the metal.

The stroke of the hydraulic punch press is regulated by a feedback valve, leading to an increase in the accuracy of the ram movement and improved punching precision.