Overview of Shearing Machine

A Sheet Metal Shearing Machine is a specialized tool used in the sheet metal industry for cutting metal plates into various shapes and sizes.

It is composed of several key components such as blades, pulleys, baffles, and an electric control system.

The machine's die, used for cutting metal plates, can be found in different shapes, including straight blades and round blades.

Sheet metal shearing machines are widely used in various industries, such as automotive and aerospace manufacturing, machinery production, household appliance production, and construction.

The effectiveness of a Sheet Metal Shearing Machine is determined by several factors such as its shearing capacity, accuracy, speed, and reliability.

What Are the Types of Shearing Machines?

Depending on the drive mode, common types of shearing machines mainly include manual sheet metal shearing machines, mechanical shearing machines, hydraulic shearing machines, and pneumatic shearing machines.

Manual sheet metal shears are equipment that can perform cutting of plates by manually moving the blade up and down.

These shears are easy to operate and suitable for cutting small plates, but their cutting accuracy is low and cannot meet the requirements of large plates.

The mechanical shearing machine operates using a power device consisting of a motor, flywheel, worm shaft, and clutch.

It has faster cutting speeds and more strokes per minute compared to the hydraulic shearing machine.

The flywheel of the mechanical shearing machine stores energy, allowing for a motor with lower horsepower to be used.

Mechanical shearing machines can be further divided into up-moving and down-moving types based on the operation mode.

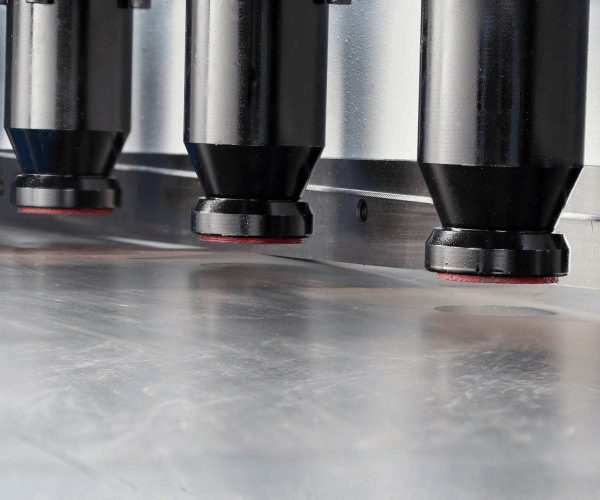

The hydraulic shearing machine is powered by a hydraulic cylinder and motor. The motor drives the hydraulic cylinder to apply hydraulic oil pressure to the piston, providing power to the upper blade's piston.

The hydraulic shearing machine has a longer stroke and can handle different load capacities.

Materials cut using a hydraulic shearing machine have a smooth surface with minimal markings.

These machines are known for their large shearing force, stable operation, and good controllability.

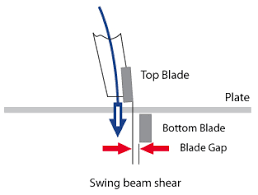

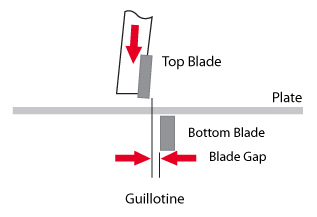

The hydraulic shearing machine can be categorized into two types: the swing beam shearing machine and the guillotine shearing machine.

The swing beam shearing machine performs the shearing movement by swinging the tool rest, resulting in high speed, high shearing accuracy, and high efficiency.

The guillotine shearing machine can be powered either by hydraulic or mechanical means.

It consists of a working table, upper and lower blades, a hydraulic piston, a clamping tool, and a blank holder.

This machine can cut plates of varying thicknesses and lengths. The movable blade of the guillotine shearing machine can be straight or angled to reduce the cutting force.

With fast cutting speed, the guillotine shearing machine can handle large cutting thicknesses and lengths, making it ideal for mass production.

However, the cut edges produced are rough and unattractive.

The pneumatic shearing machine refers to the equipment that uses a pneumatic system to control the up-and-down movement of the blade for plate cutting.

The pneumatic plate shearing machine offers high shearing speed and accuracy, as its blade movement can be adjusted through air pressure.

It is commonly used for cutting special plates, such as those with high hardness and strength.

Thanks to its high cutting speed and accuracy, the pneumatic shearing machine is ideal for high-speed and high-precision cutting.

There are two main types of shearing machines for cutting plates: linear and circular.

The linear shearing machine is powered by hydraulic devices and can handle thicker metal plates.

The circular plate shearing machine is powered by a motor and can cut circular metal plates.

Each type of shearing machine has its own advantages and is suitable for different cutting needs.

Users can select the most suitable type of shearing machine based on their needs and the properties of the material.

For instance, manual shearing machines are ideal for cutting small plates, while large plates may require a guillotine shearing machine or a pneumatic shearing machine.

What Are the Main Components of the Shearing Machine?

The main components of a shearing machine are the working table, upper and lower shearing blades, clamping tools, baffles, and electrical elements.

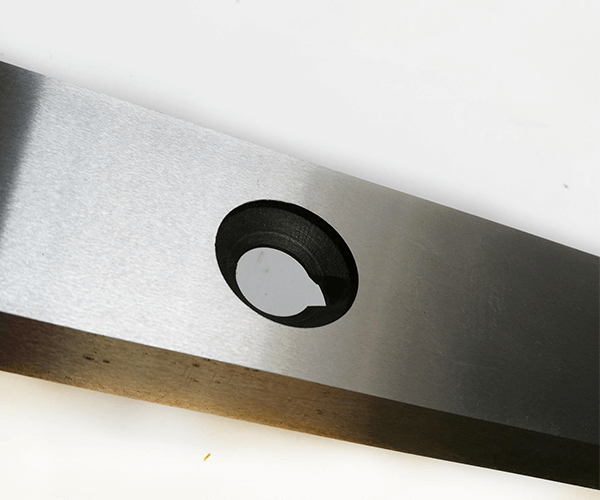

The blades, typically made from high-strength steel with good hardness and wear resistance, are the primary working component of the machine.

They can be moved up and down to perform the cutting of the sheet metal. The clamp is used to secure the metal sheet in place for accurate cutting.

The baffle serves as a protective measure for the plate shearing machine. Made from high-strength metal materials, it guards against external forces impacting the plate.

The baffle is typically installed near the blade edge of the machine for maximum safety of the workers.

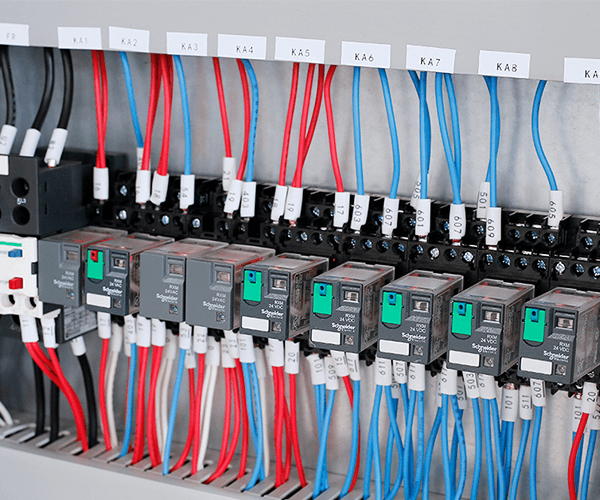

The electrical elements control the operation of the shearing machine and consist of a circuit board, motor, and controller.

These elements monitor and control the machine's running state to ensure safe operation.

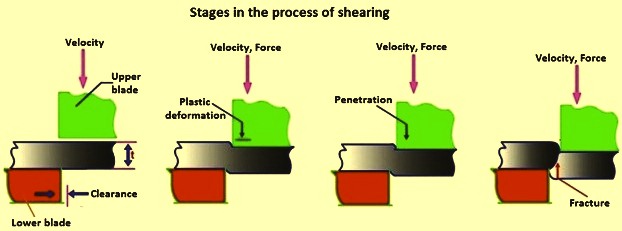

What Is the Working Principle of the Shearing Machine?

The working principle of a shearing machine is to cut sheet metal into the desired size and shape by moving its blade up and down.

To begin, the plate must be placed on the blade, ensuring it makes contact with the blade.

The machine is then activated by controlling the electrical elements to start the motor, causing the blade to move up and down.

The driving system then powers the blade to shear the sheet.

Throughout the process, a protective device is in place to ensure safety and prevent the plate from being affected by external forces.

The speed of the blade is also adjusted by the shearing machine, based on the type and size of the material being worked on, to ensure accurate shearing of the plate.

Features of the Shearing Machine

The shearing machine precisely cuts metal plates to the desired size through a moving blade that moves up and down.

The speed of the blade can be controlled via electrical elements, ensuring accurate cuts.

This machine is capable of cutting various materials, including stainless steel, aluminum, copper, and other types of plates.

It is user-friendly and safe, requiring only a basic understanding of its operation for successful use.

The shearing machine also features safety components that protect both the plates and workers from external forces.

What Is the Shearing Machine Mainly Used for?

The shearing machine provides efficient support for industrial production with its high-precision and high-speed cutting capabilities.

These machines are widely used in industries such as machinery manufacturing, aerospace, and automobile manufacturing.

In the aerospace industry, for instance, the shearing machine can be utilized to cut high-strength steel plates to produce aircraft parts.

The machine can also be utilized in the production of automobile components, such as bodies and doors, by cutting both steel and aluminum plates.

In addition to industrial applications, shearing machines are also used in various other fields, including household appliances, electronics, and building decoration.

For example, in the household appliance industry, the shearing machine can be used to cut stainless steel plates for products such as refrigerators and air conditioners.

In the electronics industry, it can be used to cut aluminum plates for the production of computer and mobile phone shells.

What Are the Blade Materials of Shearing Machine?

The blades of the shearing machine are mainly composed of high-speed steel, carbon steel, and other materials.

High-speed steel is a commonly used blade material that is characterized by its high wear resistance and rigidity.

Thanks to its high stiffness, high-speed steel blades can significantly enhance the cutting efficiency of the shearing machine.

After undergoing fine processing, they can also improve the machine's shearing accuracy.

Carbon steel, on the other hand, is an economical blade material with high toughness.

The high toughness of carbon steel blades makes them resistant to vibrations and deformations during shearing.

Additionally, after undergoing heat treatment, they can also improve the shearing accuracy of the machine.

In conclusion, the blade materials of the shearing machine can include high-speed steel, hard alloy, carbon steel, and others.

The choice of blade material depends on the specific working conditions and budget of the machine.

Future Development Trends of the Shearing Machine

The future direction of the shearing machine's development may be impacted by various factors, including economic growth, market demand, and technological advancements.

With the rise of intelligent technology, the shearing machine is expected to become more advanced, featuring additional intelligent functions such as automatic blade position adjustment and automatic plate type and thickness identification.

The implementation of digital technology can lead to more efficient production management and quality control, making the shearing machine even more efficient.

In addition, the integration of the shearing machine with other equipment is expected to improve production efficiency and quality by achieving seamless connections.

Finally, the shearing machine will strive to reduce its environmental impact by reducing energy consumption and the emission of pollutants.

Conclusion

This article provides an overview of the main types, components, working principles, features, applications, and blade materials of shearing machines.

Plate shearing machines are widely used in the manufacturing industry and are a highly versatile piece of equipment.

When purchasing a shearing machine, it is important to consider its functions, price, warranty, and other factors in detail.

ADH is a reputable sheet metal processing machine manufacturer with 20 years of experience.

The quality and performance of their press brake, plate shearing machine, laser cutting machine, and other machines are guaranteed.

FAQs

What Are the Famous Manufacturers of the Shearing Machine?

Plate shearing machines are widely produced and sold by many manufacturers, including well-known brands such as Adira, Amada, JMT USA, Cincinnati, Baykal, LVD, Safan Darley, and ADH.

These manufacturers offer high-quality and high-performance shearing machines that are widely appreciated by customers.

Price of the Shearing Machine

The price of a shearing machine is influenced by various factors, including the manufacturer, quality, functions, and performance.

Additionally, market demand and supply also impact the price of these machines.

For more detailed information, it is advisable to reach out to the manufacturer for consultation.