I. Introduction

Press brake bending is one of the important procedures in the sheet metal processing industry. It involves forming sheet metal into the desired profile by applying force to the workpiece.

This process is generally performed using a press brake - a mechanical processing tool that is mainly used for sheet metal bending and forming.

Bending is a common process used for manufacturing parts and workpieces in various industrious fields. It can deal with small parts as well as large workpieces.

Due to the different thickness, hardness of the sheet metals, and different shapes of anticipated profiles. Therefore, we need press brakes with different tonnage and pressure to bend sheet metals.

Bending stretches and compresses sheet metal. External force only changes the shape of the metal plate.

The length of the outer part of the sheet metal will be elongated, while the inner part will be compressed, and the length will be shortened. However, the length of the neutral axis remains unchanged.

The ductility of sheet metal allows its shape to change while other parameters, such as volume and thickness, remain constant.

In some cases, bending may alter the external characteristics of the sheet metal. Additionally, bending can change the moment of inertia of workpieces.

The tonnage of press brakes is determined by the driving source, which can be mechanical press drive, hydraulic press drive, pneumatic press drive, or servo press drive.

Furthermore, it's also necessary to match punches (upper dies) and dies (lower molds) with different heights, shapes, and V-opening sizes.

Generally, bending dies are made of gray cast iron or low-carbon steel. However, the materials of punches and dies vary from hardwood to carbide according to the workpiece.

The sheet metal is placed properly on the bottom die, and the punch is lowered on the die through the power of the ram. The bending process involves repeating the bending stroke several times to achieve the desired profiles.

The metal plate will rebound slightly after bending. To ensure that the predetermined bending radius and bending angle remain unchanged, the bending radius should be set to a value greater than the predetermined bending radius during operation.

As a result, the final bending angle will become smaller.

II. What is Press Brake Bending

Definition and explanation

Press brake bending is a manufacturing technology that uses a press brake to bend metal sheets into diverse shapes. The press brake exerts pressure on the metal sheets, forcing them to match the shape of the die and form the bend at a predetermined angle.

The bending process involves placing the metal sheet workpiece between the upper tool (punch) and the bottom tool (die). The punch descends the workpiece into the die, forcing the metal to bend and take the shape defined by the punch and die tools.

Basic components of a press brake

Press brake is composed of three main parts:

Frame: supports the whole machine’s structure, and usually a welded C-shaped frame.

Ram or top tool: the moving upper beam that holds the punch tool. It applies the bending force.

Bed or bottom tool: the stationary lower table that supports the die. The workpiece rests on the die.

Other essential parts include hydraulic or electric systems that drive the ram, the back gauge for positioning the workpiece, and the control system (CNC or manual).

Bending process overview

The classic press brake bending process includes the following procedures:

Firstly, the flat sheet metal is positioned on the bottom die. Then, the tool will clamp the workpiece between the top punch and bottom die. After that, the punch will descend and press the metal sheet into the die, making it bend.

The bending angle is determined by the penetrating depth of the top punch. Then, the punch retracts and releases the bent workpiece. The bent part is moved, and the procedures are repeated for the next workpiece.

III. Types of Press Brake Bending

Different types of sheet metal bending methods are based on the relationship between the end tool position and the material thickness. These methods also differ in the method of plastic deformation of the plate.

Although the bending techniques are different, the tooling and configurations are basically the same. The material, size, and thickness of sheet metals also determine bending methods.

The bending dimension, bending radius, bending angle, bending curvature, and bending position in the workpiece are also essential for the bending methods.

V bending is one of the most common types of sheet metal bending methods. It requires a V-shaped punch and die.

During the bending process, the metal plate is placed on the V-shaped die, and the punch presses the metal plate into the V-shaped die under the action of pressure.

The bending angle of the metal plate is determined by the pressure point of the punch. The angles and shapes of the dies include acute angle, obtuse angle, right angle, etc. V-bending can be subdivided into air bending, bottoming, and coining.

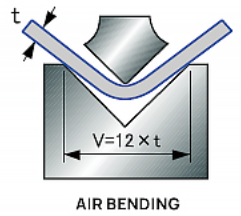

Air Bending

Air bending is also called partial bending because the workpiece is not in full contact with the die. In air bending, the sheet metal is only connected with the shoulder of the die and the tip of the punch.

The punch is pressed onto the plate and passes through the top of the die into the V-shaped die opening but does not contact the surface of the V-shaped opening.

Therefore, the distance between the punch and the sidewall of the die must be greater than the thickness of the metal plate. Air bending is the bending method with the least contact with sheet metal.

The equipment only needs to contact the sheet metal at three points, namely, the punch, punch tip, and die shoulder. Therefore, the relationship between the bending angle and the tooling angle is not very significant.

The depth of the punch pressing into the V-shaped opening is the important factor that affects the bending angle. The greater the pressing depth of the punch, the sharper the bending angle.

The bottom die and punch used in air bending do not need to have the same radius, as the bending radius is determined by the elasticity of the sheet metal.

Advantages

Because the punch tip does not need to be pushed past the metal's surface, it requires less bending force or tonnage. Moreover, it does not require too many tools, and the operation is simple and flexible.

Minimal contact between sheet and tooling results in less surface marking. It is able to bend a range of material types and thicknesses.

Disadvantages

It will result in a certain degree of spring back after bending. Overbending is often needed to compensate for springback.

Therefore, the actual bending angle should be sharper than the preset bending angle during bending to achieve the final bending angle.

In addition, in air bending, because the metal plate and die are not in full contact, ensuring bending accuracy is difficult. Also, it is challenging to maintain a highly accurate stroke depth.

Not well suited for parts requiring very tight angular tolerances. Inconsistencies in material thickness and properties can lead to angle variations.

Bottoming

Bottoming is also known as bottom pressing, bottom bending, or bottom striking. Like air bending, bottom bending also requires a punch and die. The geometry of the punch and die is matched to the desired final bend angle, typically 90°.

In bottom bending, the punch presses the metal plate to the bottom of the die, so the angle of the die determines the final bending angle of the metal plate.

The release of the punch will cause the sheet metal to spring back and contact the die. Excessive bending helps to reduce spring back. Using more force will also reduce the spring back effect and provide better accuracy.

The difference between air bending and bottom bending is in the radius. The radius of the die determines the inner radius of the bending sheet metal.

The width of the "V" shaped opening is usually 6 to 18 times the thickness of the sheet plate.

Advantages

In bottom bending, because the angle of the die is fixed, the bending accuracy is higher, and the spring back is smaller. Its bending angle is more precise and consistent than air bending, usually within ±0.5°.

It can achieve a smaller bending radius than air bending, and its bending line and corners are acute and outlined.

Disadvantages

The die cost is high due to the precision ground dies required for each bending angle and material. High contact forces between the punch, material, and die increase the tool's abrasiveness.

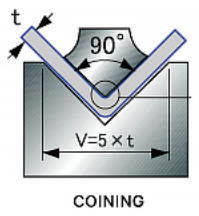

Coining

Coining is also a widely used bending method. The word “coining” comes from coin making. In the United States, in order to print Lincoln's profile on a coin, a large tonnage machine is used to compress the coin to obtain the same image as that on the mold.

In coining, its punch and metal plate are at the bottom of the die. The force produced by the punch is 5 to 8 times that of air bending. In this way, the sheet metal will hardly spring back.

Advantages

The material is utterly matched with the shape of the die and has high precision and good repeatability.

The spring back is the smallest because it overcomes the material's elastic limit. There is no need to over-bend. The bending accuracy of coining is extremely high, and the bending radius is small.

Disadvantages

Its manufacturing cost is also very high. It is not suitable for small batch sizes or varying bend angles. In this bending process, friction easily damages the press brake and tooling.

Moreover, more toolings need to be equipped. Basically, each plate thickness needs different punches and dies. Also, consider the angle, radius, and die opening.

Comparison between the above three types of bending

| Characteristic | Coining | Bottom Bending | Air Bending |

| Principle | Use high tonnage to compress the metal sheet between the precisely matched punch and die, ensuring that the material fully conforms to the shape of the tool. | The punch forces the metal sheet completely into the bottom of the V-shaped die, matching the required final bending angle. | A common metal sheet forming process carried out on a punch press, where the metal sheet is placed on a V-shaped die and the punch presses the material into the die without touching the bottom. |

| Required pressure | Very high, 5-30 times that of air bending | High, usually 3-5 times that of air bending | Relatively low |

| Angle accuracy | Use high tonnage to compress the metal sheet between the precisely matched punch and die, ensuring that the material fully conforms to the tool's shape. | High, usually within ± 0.5 ° | Lower, usually around ± 0.5 °, requiring over bending compensation for spring back |

| Springback amount | Minimum, exceeding the material's elastic limit | When high angle accuracy is required, and the output is large | Larger, usually requiring super bending |

| Die requirements | Special dies that require precision machining | Strong versatility: the same die can be used for different angles | Highest, the material completely fits the die |

| Production efficiency | Low, requiring a longer holding time for pressure | Lower, the punch needs to be pressed to the bottom of the die | High, short cycle time |

| Surface quality | There are obvious indentations and thinning at the bending point | There are certain die contact marks at the bending point | Minimum surface traces |

| Applicable occasions | When there is a high demand for angle accuracy and a large output | - High tonnage requirements - Increased risk of tool wear and breakage - Cycle time slower than air bending - Higher tooling costs - Limitations on bending geometries and angles - Metal thinning and surface marking at bend lines - Not cost-effective for small batches or varying bend angles | Low requirement for angle accuracy, small batch production, and variable materials and angles |

| Advantage | When high angle accuracy is required, and the output is large | - More precise and consistent bending angles than air bending. - Minimal springback. - Sharp, well-defined bending lines and corners. - Suitable for bending high-strength materials. - Capable of achieving smaller inside bend radii than air bending. | - High flexibility - Requires less pressure compared to bottom bending or stamping - Less contact between metal sheet and tool, resulting in fewer surface marks - Faster cycle time compared to bottom bending - Capable of bending various types and thicknesses of materials |

| Shortcoming | - Higher bending force and tonnage than air bending - Slower cycle times due to the need for full bottoming of the punch - Increased tooling costs - Tool wear due to higher contact forces - Greater risk of tool damage or overload - Marks or scratches on the metal surface where the tool contacts - Limited formability compared to air-bending | - Higher bending force and tonnage than air bending - Slower cycle times due to the need for full bottoming of the punch - Increased tooling costs - Tool wear due to higher contact forces - Greater risk of tool damage or overload - Marks or scratches on the metal surface where the tool contacts - Limited formability compared to air bending | - The angular precision is lower towards the bottom bend. - Not suitable for components requiring very tight angular tolerances. - Inconsistencies in material thickness and properties may lead to angular variations. - Older, less rigid punch presses may struggle to achieve consistent angles. |

IV. What Needs To Be Considered When Bending a Metal Using a Press Brake?

Types of the Bending Materials

Before sheet metal bending, we must first make sure which materials are good for bending.

Some metal materials have good ductility, and these kinds of metals are more suitable for bending, while some metals are less malleable or brittle and are easy to be damaged or broken during bending.

Steel

- Cold-rolled steel is widely used, especially in gauges 16 to 10.

- Specific grades like A36, A1011, A1008 are popular choices. A36 is used for plates 1/4" and thicker, while A1008 is used for sheets up to 3/16" thick.

- Stainless steels like 304 (general-purpose), 316 (caustic environments), and 430 (magnetic applications) are frequently bent.

Aluminum

- 5052 and 3003 aluminium alloys are used interchangeably and are easy to form and weld. 5052 provides better strength and corrosion resistance.

- 5083 aluminium, the strongest non-heat treatable alloy, is used in marine applications requiring weldability, formability and corrosion resistance.

- 6061 aluminium is used for plates 3/16" and thicker, extruded shapes, and machined parts. It can be heat-treated for strength but is more brittle.

Bending Springback

In the bending process, the sheet metal inner surface will be compressed and the outer surface will be stretched.

Because the metal plate has a good bendability, the compressed surface will produce a certain springback after the load is relieved.

The amount of spring back is determined by materials’ properties, such as yield strength, elastic modulus, and ductility. Harder, high-intensity metal will show a larger spring back.

To compensate for spring back, the metal needs to be overbent to some extent so that it will spring back to the required final angle.

The bending radius affects the spring back of the plate. The larger the bending radius, the greater the spring back.

Using a sharp punch can reduce spring back. Because the sharp punch has a small inner radius.

Bend Allowance

Bend allowance is a critical factor to consider when calculating the length of material required for a bending operation.

It refers to the length of the neutral axis between the two bend lines, and it can vary depending on the thickness, material, and bending angle of the workpiece.

To calculate the bend allowance, you need to take into account the material's tensile strength, elongation, and thickness, as well as the bend radius and angle.

Once you have determined the bend allowance, you add it to the total flat length of the material to obtain the required material length for the desired workpiece.

It's essential to ensure that the bend allowance is accurate because even a slight miscalculation can lead to errors in the final workpiece's dimensions and shape.

By taking into account the bend allowance, you can achieve more precise and consistent results in your bending operations.

V. Conclusion

Through my passage, you can see that press brake bending is a common metal sheet forming and processing method.

It utilizes the punch to compress pressure on the metal sheet, causing its plastic deformation to bend. Air bending, bottoming, and coining are the common and effective bending methods.

If you are interested in press brake technology or are considering purchasing the equipment, you may wish to consider the ADH Machine Tool.

As a professional press brake manufacturer with over 40 years of experience, ADH can offer multiple high-quality, high-pressure press brake products that satisfy requirements from different industries and occasions. Welcome to browse our product pages and learn more about a series of press brakes.