I. Introduction

In the modern manufacturing industry, a press brake is an indispensable piece of equipment for processing metal sheets.

Its properties directly affect the precision and quality of the products. In numerous bending technologies, press brake crowning is the key to ensuring the accuracy of the bending.

Crowning is a technology designed to offset the uneven bending caused by machine tool, die, and material elastic deformation.

In brief, it can adjust the shape of the upper punch and bottom die properly during the bending to ensure the bending angle is consistent throughout the bending length, thus improving the precision and quality of the workpiece.

II. Definition and Importance of Crowning

Definition

Press brake crowning is crucial for correcting the bending accuracy of workpieces.

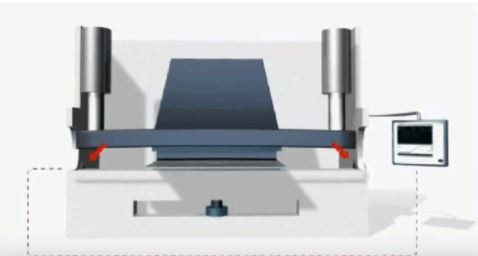

During the bending process, the oil cylinder at both ends of the press brake drives the ram to apply pressure to the workpiece.

The servo valve located above the left and right oil cylinders, as well as the positioning device below the oil cylinders, can control the lifting position of the oil cylinder.

During each bending, the servo-hydraulic system controls the position of the oil cylinder through preset parameters to ensure that the ram reaches the preset position of the controller, resulting in more accurate bending angles.

However, when bending a metal plate, the two ends of the press brake's ram are subjected to the maximum force, and the reaction force generated when the plate is bent deforms the lower surface of the ram.

As a result, both ends of the sheet metal are bent at the correct angle, but the deformation in the middle of the ram is the largest, especially when bending long metal plates.

As shown in the figure, during the bending of a metal plate, the ram of the press brake moves upward while the bed of the machine moves downward.

In order to improve bending accuracy and eliminate bending angle errors caused by ram and workbench deformation, it is necessary to compensate for their deflection.

A compensation or crowning system can be installed to generate an opposite force that balances the deflection of the ram and the workbench.

This crowning system is usually installed for large sheet metal and high-strength bending because the deflection error of large sheet metal bending is relatively large.

Importance

Before the invention of the compensation system, some press brake manufacturers used convex worktables to control crowning, but the compensation was less accurate.

With the improvement of the CNC system, the crowning system is now controlled by the CNC system.

Therefore, the operator only needs to input the length, thickness, bending angle, and other information about the bending.

The crowning system will automatically calculate the compensation values. The system can store this information and directly reuse the data during the next repeated bending procedure.

The crowning system improves the bending accuracy and efficiency of small-batch workpieces. For large tonnage and high-strength bending, the accuracy of the bending angle can be guaranteed.

Crowning includes compensating for natural deformation and bending that occur in the base and ram of the press brake during normal operation due to the bending force applied to the workpiece.

When a press brake bends the workpiece, both the upper and lower crossbeams may suffer deflection and deformation, which may have unwanted effects on the final product.

By effectively mastering press brake compensation, operators can ensure accurate bending, thereby reducing waste in the manufacturing process and improving productivity.

III. Choices of Crowning System

Crowning is typically used for large-tonnage, high-strength press brakes because the tonnage of the machine is directly proportional to the demand for deflection compensation.

However, compensation can also be used for press brakes with lower tonnage. The longer the length of the workbench and the ram of the press brake, the greater the deflection of the machine.

There are two commonly used crowning methods: hydraulic crowning and mechanical crowning. Both of them will produce upward elastic deformation in the middle of the worktable to offset the deformation of the ram and the worktable.

Mechanical crowning can be an optional device for the press brake, while hydraulic crowning is a standard device for the press brake. In modern press brakes, there are two types of crowning: hydraulic crowning and mechanical crowning.

We will introduce the working principle, advantages, and disadvantages of these two methods.

Hydraulic Crowning

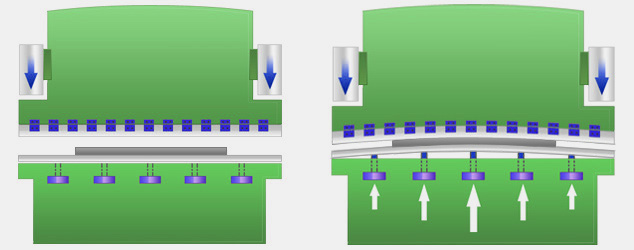

Hydraulic crowning requires a set of oil cylinders to be installed under the workbench of the press brake.

The position and size of each crowning cylinder are designed according to the deflection crowning curve obtained from finite element analysis of the ram and workbench.

Hydraulic crowning is used to achieve the crowning of the neutral plate through relative displacement between the front, middle, and rear vertical plates.

Its principle is to achieve bulging through the elastic deformation of the steel plate itself, and its crowning can be adjusted within the elastic range of the workbench.

When the ram and the workbench deform during bending, the hydraulic crowning system transmits pressure to the compensation cylinder through hydraulic pressure.

Then, the ram and the workbench produce compensating deformation, thereby reducing the influence of machine deformation on the plate.

However, this hydraulic crowning system cannot compensate for the whole workbench. Local compensation depends on the position of the compensation cylinder.

Some hydraulic crowning systems only set one compensation cylinder in the center of the workbench, although there are also multi-cylinder systems.

Numerical control hydraulic crowning sets parameters according to the length, thickness, and other data of the bending workpiece in the numerical control system.

Then calculate the required compensation values through the machine computer system and transmit the command to the compensation amplifier.

The hydraulic crowning proportional valve receives the signal sent by the compensation amplifier to control the oil cylinders under the workbench.

Compensation is carried out to reduce the deflection deformation of the plate during bending.

The hydraulic crowning system is complex, and problems such as oil leakage, loose sealing rings, and other issues may arise.

These issues can affect the amount of hydraulic compensation each time, resulting in inconsistent plate processing.

The advantage of hydraulic crowning is that with the increase in service time, the machine will not have wear problems. While mechanical crowning will have wear problems.

Compared to mechanical crowning systems, hydraulic crowning systems can provide precise control and timely adjustment of tonnage.

Mechanical Crowning

Mechanical crowning uses a wedge to compensate for the worktable. Wedge blocks can be divided into single wedge blocks and multiple groups of wedge blocks.

The mechanical crowning system composed of multiple groups of wedge blocks has more compensation points than the three compensation points of ordinary hydraulic crowning, and there is no compensation blind area.

The mechanical crowning system can realize compensation along the whole workbench. Deflection can be compensated by convex operation at any position on the length of the entire worktable.

The CNC system calculates the required crowning force according to the load force when the workpiece is bent. This force will cause deflection deformation of the ram and the vertical plate of the workbench.

The system will automatically control the relative movement of the wedge blocks to effectively compensate for the deflection deformation caused by the ram and the vertical plate of the workbench.

The folded workpiece will have high precision and a small difference in plate processing each time, making it suitable for mass production.

Compared to the hydraulic crowning system, the mechanical crowning system has some advantages such as being free of oil leakage, having a low failure rate, and being environmentally friendly.

Mechanical crowning uses a linear scale to measure the position of the feedback signal. Digital control makes the crowning value more accurate. However, with the passage of time, the wedge may wear, which can affect the compensation effect.

The mechanical crowning operation has high requirements. If the same workpiece needs to be bent several times, the worker needs to make real-time adjustments.

Even if the workers have sufficient experience, unpredictable errors can occur. Therefore, high requirements for mechanical compensation operations are needed.

If the workpiece does not need to be bent many times and the worker is skilled, mechanical crowning can be considered for its workpiece accuracy.

Comparison Between Hydraulic Crowning and Mechanical Crowning

| Project | Hydraulic Crowning | Mechanical Crowning |

| Advantage | 1. With increasing usage time, there will be no issues of wear and tear. 2. Compared to mechanical crowning, it can provide precise control and timely tonnage adjustment. | 1. It is possible to compensate the entire workbench, and deviation compensation can be achieved at any position along the length of the workbench through convex operation. 2. Folding the workpiece will have high precision and minimal differences in each sheet processing, suitable for mass production. 3. Compared with hydraulic crowning systems, it is oil-free, with low failure rates and environmentally friendly. |

| Disadvantage | 1. Compensation cannot cover the entire workbench; partial compensation depends on the position of the compensating cylinder. 2. The system is complex and may experience issues such as oil leakage and loosening of seals, affecting the amount of hydraulic compensation each time and leading to inconsistent sheet metal processing. | 1. As time passes, the wedges may wear out, affecting the compensation effect. 2. There is a high requirement for operation. If the same workpiece needs to be bent multiple times, workers need to adjust in real-time. Even with extensive experience, unpredictable errors may occur, hence the high demand for precision in mechanical compensation operations. |

IV. Calculating and Setting Bending Compensation for Different Workpieces

Understanding the Need for Compensation

The elastic modulus of materials: different materials have different elastic moduli, which affect the degree of elastic deformation of materials under stress.

Workpiece thickness: the larger the thickness, the higher its rigidity during bending, requiring more compensation.

Workpiece length: the longer the length, the greater the deformation of the machine tool and mold during the bending process, thus requiring more compensation.

Calculate Compensation Amount

Compensation amount calculation usually depends on empirical formulas, finite element analysis (FEA), or the machine tool’s compensation algorithm. The following is a simplified calculation procedure:

Step 1: Ensure the basic parameters

Ensure the material type, thickness, and length. Acquire or calculate the elastic modulus and yield strength of a material.

Step 2: Use empirical formulas or software

As for simple applications, you can utilize empirical formulas to estimate compensation. These formulas are usually based on material type, thickness, and length.

For more complex or accurate applications, you can use finite element analysis software (such as ANSYS or SolidWorks Simulation) to perform simulations and accurately calculate the amount of compensation required.

Many modern press brakes have installed built-in compensation algorithms, which allow operators to input the basic parameters of the workpiece, and the machine will calculate the required compensation amount.

Step 3: Set the compensation value

According to the calculation and simulation results, the compensation value will be input via the machine tool's control system.

For hydraulic or mechanical systems, ensure that the compensation setting matches the machine tool's actual performance and limitations.

Actual Application and Adjustment

Trial bending is needed before bending to verify the accuracy of the compensation setting. The compensation amount needs to be adjusted based on the bending results to achieve the required bending angle and precision.

Record the required compensation setting for workpieces with different materials and specifications, which is convenient to refer to in the future.

Continuous Monitoring and Optimizing

Check and maintain the crowning system regularly to ensure accuracy and reliability. Collect and analyze the production data and optimize the compensation setting to improve production efficiency and product quality.

V. Conclusion

In a nutshell, press brake crowning plays a pivotal role in press brake manufacturing. By setting reasonable bending compensation parameters, the spring back of the bending workpiece can be effectively reduced, improving the bending accuracy while ensuring product quality.

With the rapid development of technology, technologies like advanced sensors, data analysis, and machine learning will be applied to press brake crowning, achieving instant, dynamic, and adaptable crowning control and further enhancing press brake processing accuracy and efficiency.

In this era of rapid technological development, it is important to choose an experienced and advanced press brake manufacturer.

ADH Machine Tool, a professional press brake manufacturer for over 40 years, not only offers high-quality and high-accuracy press brakes but is also dedicated to innovation and research to meet the changing requirements of the market.

We sincerely invite you to browse our press brake page and learn more about our products' details and technique advantages.