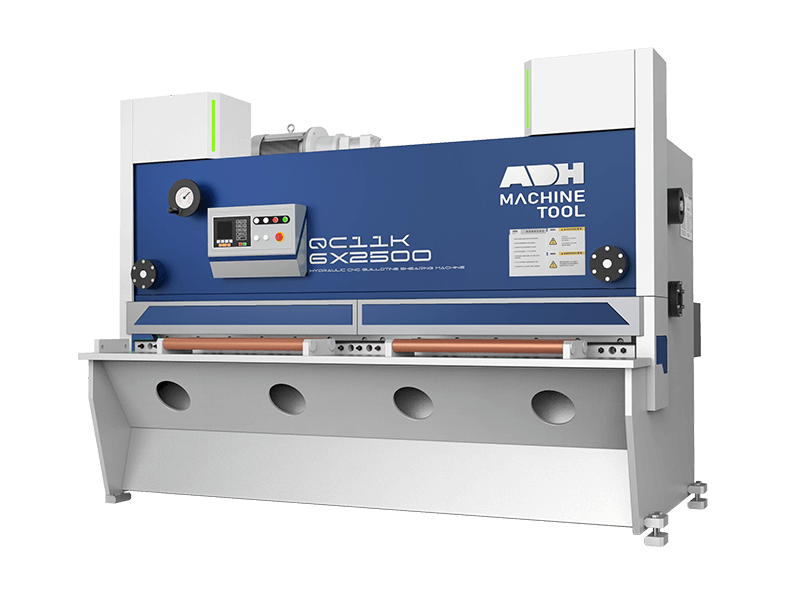

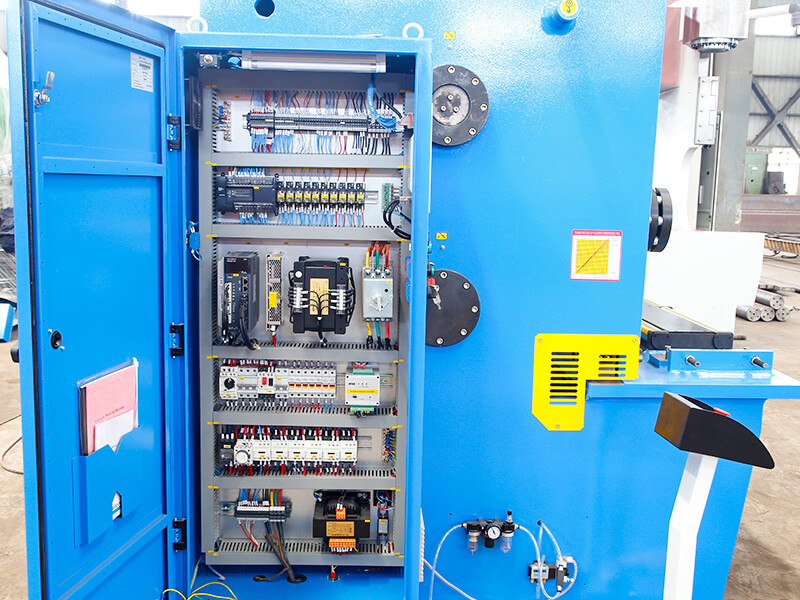

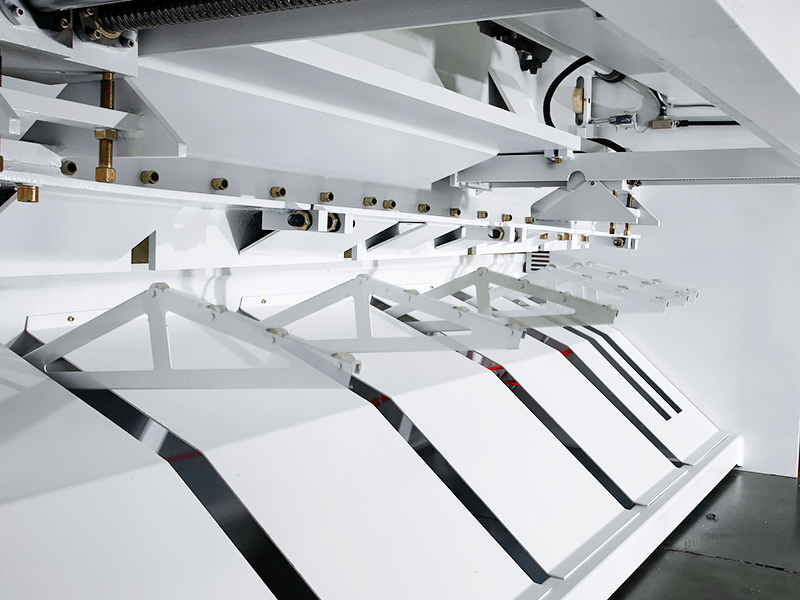

Standard Machine Tools Tradex Pvt. Ltd. has carved a niche for itself as an Innovative Importer, Authorized Distributor for the gamut of high quality engineering & sheet metal machineries. It is a wonderful experience and journey working with ADH, one of the Top World class manufacturers of

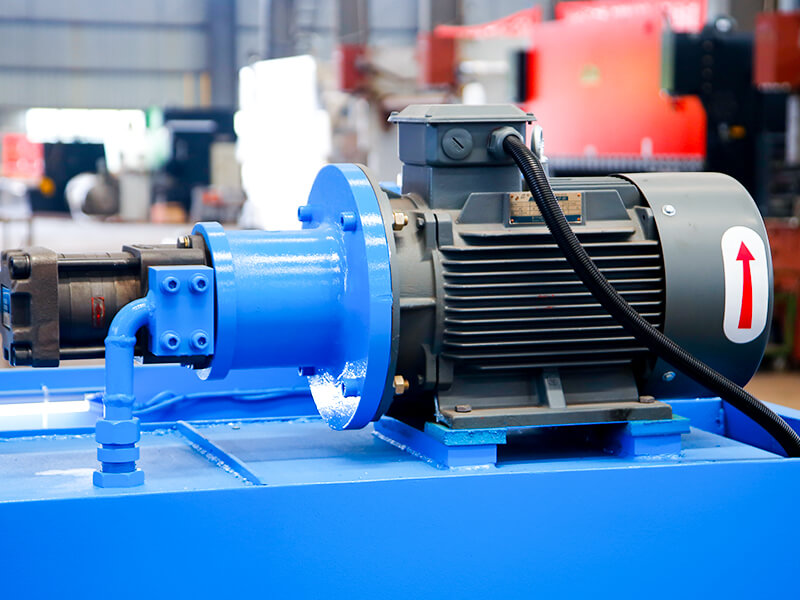

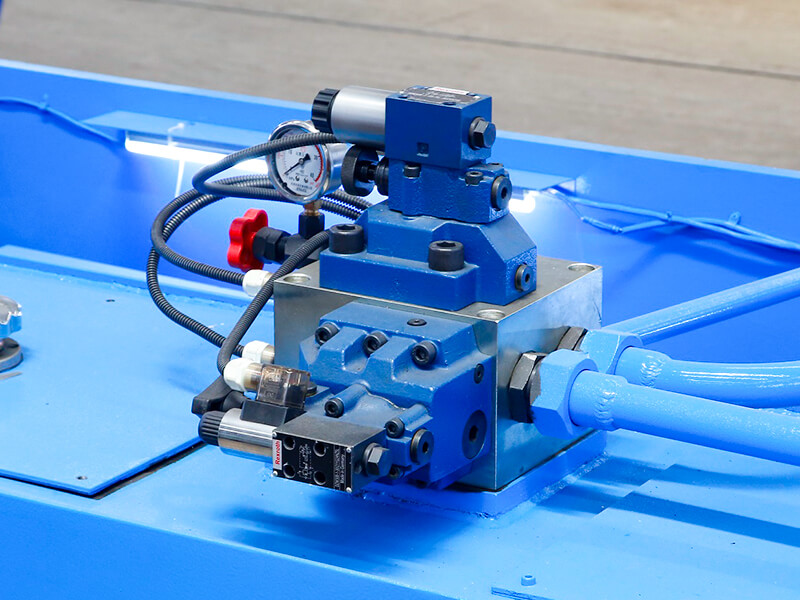

CNC Press Brake, Fibre Laser, Shearing and Turret Punch Press machines. ADH machines are Robust in Design, Stringent in Quality and Spectacular in Looks. Most satisfactory part is the Performance of the machines appreciated by all customers. Due to the Prompt response and strong support of ADH in Marketing, On-time delivery commitments, Quick after Sales Service; we have sold more than 35 machines in past two years in Western region of India. Associating with ADH with a futuristic outlook has always enabled us gain an edge over the competition in Indian Market.