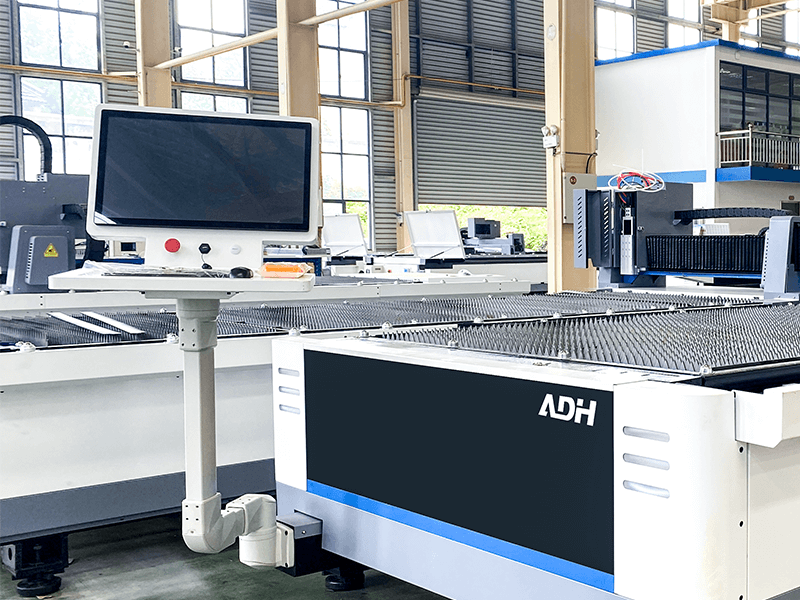

| Modell | ULFT/ULET |

|---|---|

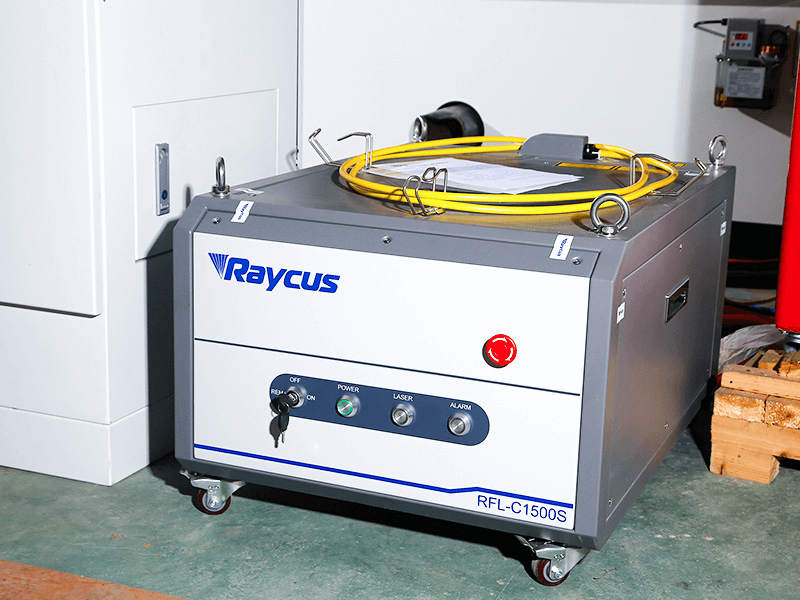

| Laserleistung | 1500W/3000W/6000W |

| Schnittbereich | 3*1.5(m)/4*1.5(m)/6*1.5(m)/6*2.0(m)/6*2.5(m) |

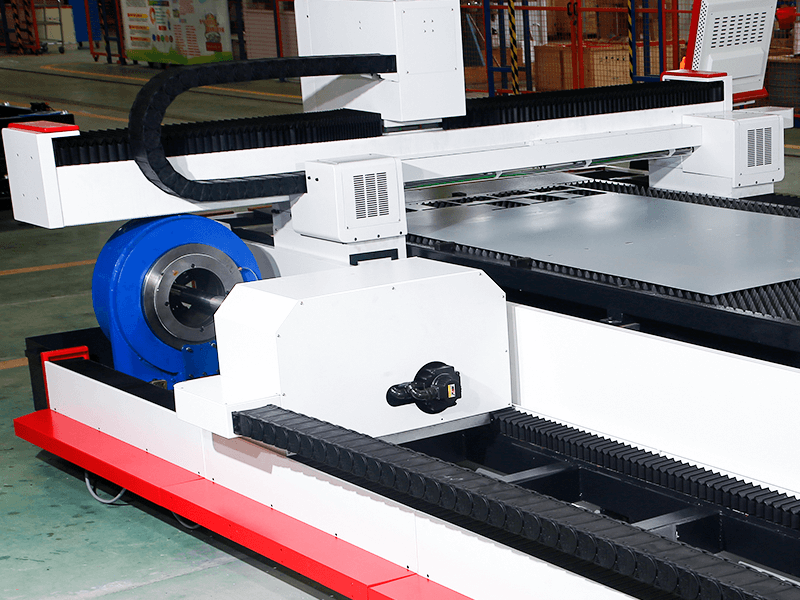

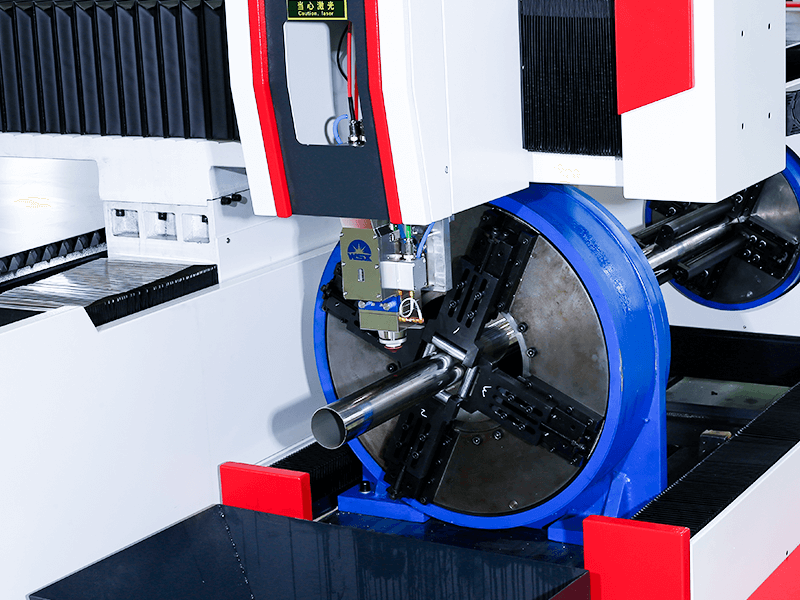

| Maximale Größe des Futters | 220mm/350mm |

| Schnittlänge Platte/Rohr | 3000mm/4000mm/6000mm |

| Maximale Fahrgeschwindigkeit | 90m/min |

| Maximale Beschleunigung | 1.2g |

| Ortungsgenauigkeit | ±0,05 mm |

| Wiederholte Positionierungsgenauigkeit | ±0,02 mm |

| Betriebsspannung | 380V/50Hz |

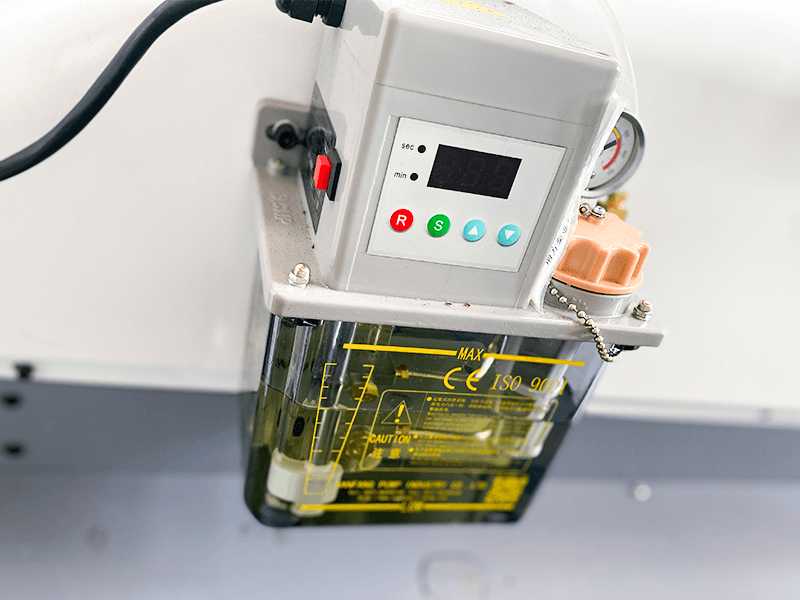

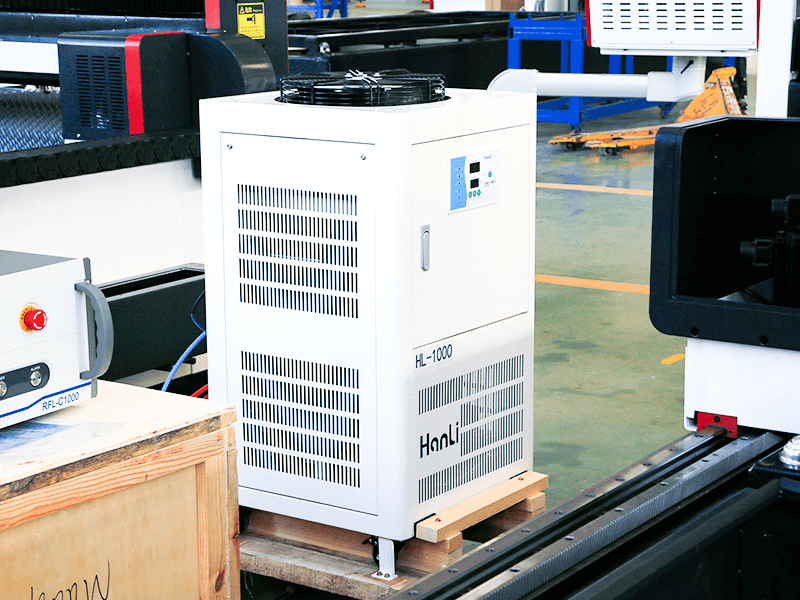

| Methode der Kühlung | wassergekühlt |