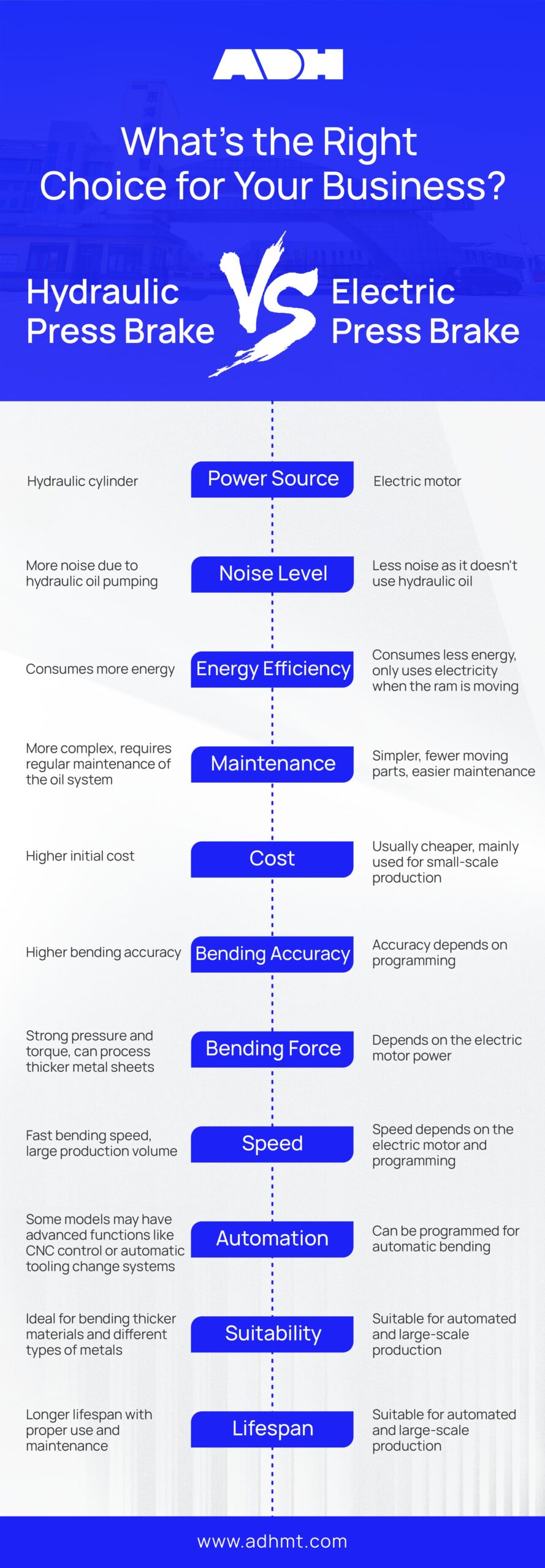

If you work in the sheet metal bending industry, you must be familiar with press brakes. A press brake is an important tool that can bend, shape, and cut metal plates into various forms and sizes.

With the development of technology, the technology of press brakes continues to upgrade, from manual to electric. Nowadays, the most widely used press brakes are hydraulic and electric press brakes.

This article will discuss the differences, advantages, and disadvantages of these two types of press brakes to help you make a more informed choice.

What Are Hydraulic Press Brakes?

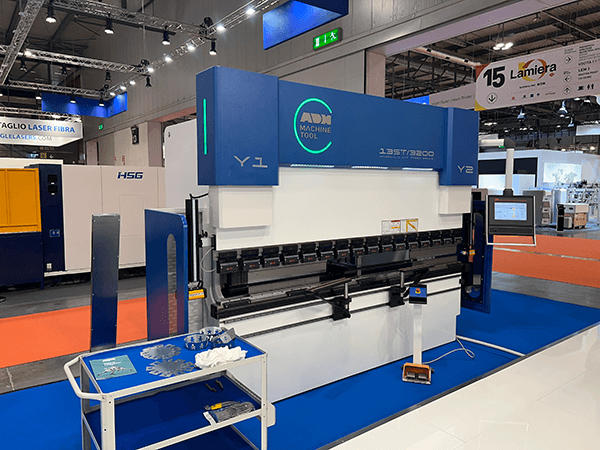

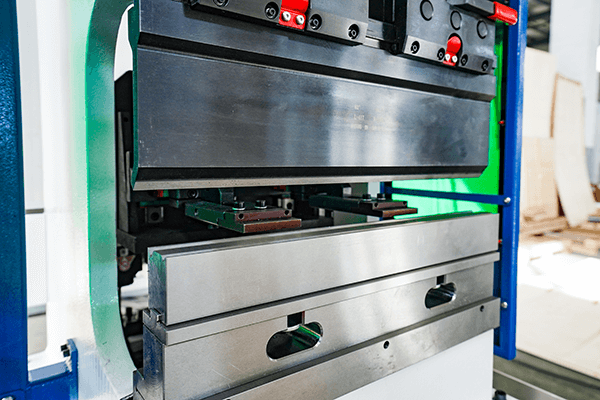

Hydraulic press brakes have been dominant in the field of sheet metal bending since their inception. The power source of the hydraulic press brake is the hydraulic cylinder, which pushes the ram to apply force to the metal plate for bending.

The hydraulic press brake has a hydraulic system where hydraulic oil is pumped into the cylinder to generate force. The pressure generated by the synchronous hydraulic cylinder forces the crossbeam or ram to press down onto the bending metal plate.

The hydraulic system provides high tonnage for hydraulic press brakes, suitable for heavy-duty bending. The hydraulic system can also accurately control the movement of the ram, providing accurate and consistent bending.

The hydraulic press brake also includes a mechanical hydraulic hybrid system and an electric hydraulic system. Each type of hydraulic press brake has its own unique functions and advantages.

Some hydraulic press brakes may also have more advanced functions, such as CNC control or automatic tooling change systems. The hydraulic press brake has a large tonnage range and is ideal for bending thicker materials.

Moreover, it can also bend different types of metals, from aluminum to stainless steel. The hydraulic press brake is also very durable, and proper use and maintenance can extend its service life.

How Does A Hydraulic Press Brake Work?

The hydraulic press brake uses a motor-driven hydraulic pump to transport hydraulic oil to the valve, guiding the pressurized oil to the cylinder. The hydraulic cylinder pushes the ram downward to apply pressure on the metal sheet, causing it to bend into the desired shape.

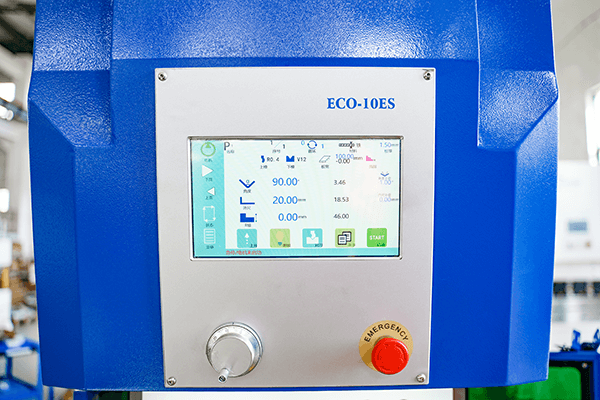

The operator places the metal sheet on the workbench, and the back gauge needs to clamp the material to prevent it from moving during the bending process. The back gauge can be manually adjusted or automatically adjusted by a CNC controller.

The operator presses the pedal or activates the hydraulic system through the controller. The hydraulic oil is pumped into the cylinder, and the pressure generated causes the ram to apply pressure to the metal plate to achieve bending.

The size of the bending force and the length of the bending can be set according to the required workpiece size. After a bending is completed, the hydraulic system releases pressure, allowing the ram to move back to its original position.

Through this precise and repetitive bending, a precise workpiece can be completed.

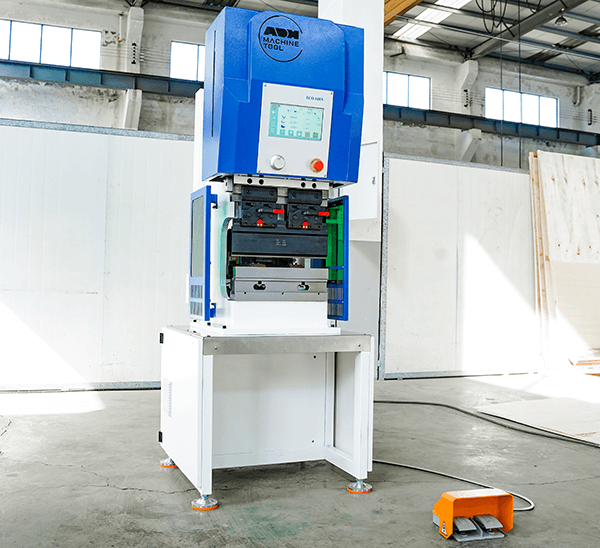

What Are Electric Press Brakes?

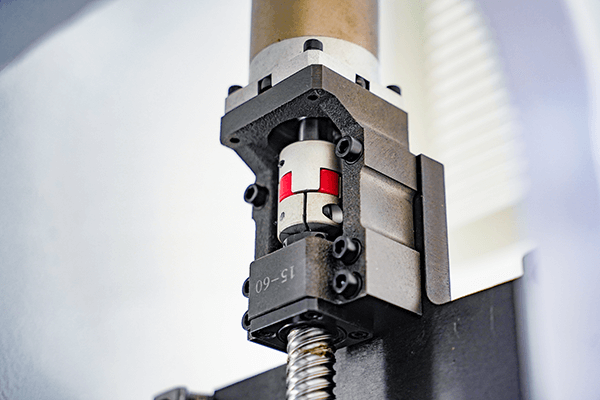

Electric press brakes are also processing machines used for metal bending and forming. Unlike hydraulic press brakes, electric press brakes use electric motors instead of hydraulic oil to provide power to the ram.

The electric motor drives the ball screw or belt to move the ram and apply pressure to the metal plate.

Due to the fact that the electric motor does not use hydraulic oil to generate pressure, it makes less noise when used. And the power of the electric press brake is only consumed when the ram moves, which can save energy consumption.

The body and structure of the electric press brake are simpler, with fewer components and easier maintenance. The types of electric press brakes include fully electric press brakes and hybrid electric press brakes.

The fully electric press brake only uses an electric motor as the power source to push the ram to move.

The hybrid electric press brake uses both an electric motor and a hydraulic system to provide power support. Electric press brakes can be programmed for automatic bending, making them suitable for automated and large-scale production.

How Does An Electric Press Brake Work?

The working principles of electric press brakes and hydraulic press brakes are basically similar, with the main difference being the different power sources. The electric press brake uses an electric motor to drive the ram to move downwards and apply pressure to the metal sheet for bending.

After each bending step is completed, the motor releases pressure and the ram returns to its original position. By repeating this process, the bending of the workpiece is achieved.

The hybrid electric press brake is powered by a combination of an electric motor and a hydraulic system.

Hydraulic Press Brake vs. Electric Press Brake: Which is Better?

The hydraulic press brake is a widely used machine due to its powerful power and versatility. Electric press brakes are a relatively new technology that has become increasingly popular in recent years due to their energy efficiency and automation capabilities.

Both types of press brakes have their unique characteristics, with significant differences in structure, working principle, performance, and other aspects. Choosing the appropriate press brake depends on your application needs, budget, and production volume.

Below is a detailed comparative analysis of these two devices.

Structural Differences

- The hydraulic press brake is mainly composed of a workbench, hydraulic system, control system, and frame.

- The hydraulic system includes components such as the main oil cylinder, oil tank, oil pump, and directional valve.

- The hydraulic system uses the pressure generated by pumping hydraulic oil to achieve up and down movement of the ram, thereby completing the bending of the sheet metal.

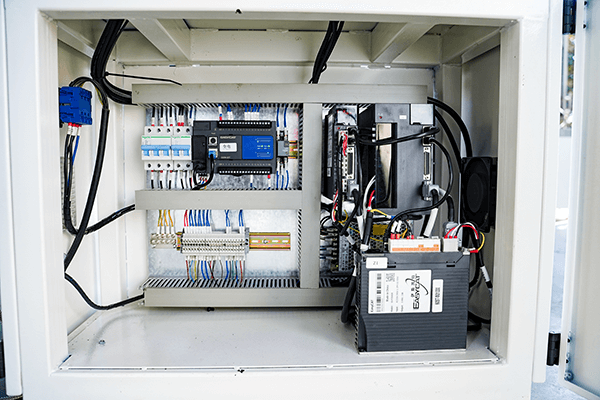

- Electric press brakes usually include ram, workbenches, electric motor transmission mechanisms, cantilever devices, electronic control systems, etc.

- Its transmission method is the electric motor drive, which drives the ram and workbench up and down through transmission mechanisms such as gears and reducers.

Differences in Working Principles

- The hydraulic press brake mainly pumps hydraulic oil into the cylinder through a hydraulic cylinder, causing the cylinder piston to move upwards.

- From this, push the ram down and the workbench up to achieve the bending of the sheet.

- The electric press brake is composed of a transmission mechanism through an electric motor.

- This drives the ram and the workbench to move up and down, achieving the bending of the sheet metal.

- In contrast, the working principle of hydraulic press brakes is more stable and reliable.

Performance Differences

The hydraulic press brake has the following characteristics:

- High bending accuracy: Hydraulic press brakes can achieve higher bending accuracy by controlling

- parameters such as oil flow rate and cylinder piston stroke.

- High bending force: Hydraulic press brakes have strong pressure and torque, and can process thicker metal sheets.

- Fast bending speed: Adopting hydraulic direct drive, the speed can be adjusted, the bending speed is fast, and the production volume is large.

- Good stability: The hydraulic system can adjust the pressure, which can better control the bending angle and accuracy, and the bending effect is stable and reliable.

The electric press brake has the following characteristics:

- Simple and convenient operation: the electric press brake is easy to operate, does not require professional personnel, and has low investment costs.

- Automation: electric press brakes can be programmed to automatically perform multiple bends, reducing the need for manual labor.

- Low noise: due to the lack of hydraulic oil being pumped, the operation of electric press brakes is quieter than that of hydraulic press brakes.

- Easy maintenance: the transmission mechanism is relatively simple, with fewer moving parts than hydraulic press brakes, making maintenance easy.

- Energy efficiency: electric press brakes consume less energy and only use electricity when the ram is moving.

- Cost: Electric press brakes are usually cheaper than hydraulic press brakes and are mainly used for small-scale production.

Conclusion

When deciding which type of press brake to use, please consider your business needs, production capacity, and energy efficiency goals. If you use thicker materials that require higher tonnage or precise control of the bending process, a hydraulic press brake may be a better choice.

On the other hand, if you prefer machines with low energy consumption, high automation, and low noise, electric press brakes may be a better choice.

Compared to electric press brakes, hydraulic press brakes often have a higher initial cost. However, in the long run, well-maintained hydraulic press brakes can save money because they have a longer lifespan.

We are a manufacturer of professional press brakes, laser cutting machines, shearing machines, and other machines with a history of 20 years. If you are interested in purchasing a press brake now, you can browse our official website. If you are interested in our products, you can contact our sales personnel.

FAQs

- Which press brake is more expensive?

The initial purchase price of hydraulic press brakes is expected to be 50%higher than electric press brakes of similar tonnage and length, as hydraulic press brakes require hydraulic systems and higher maintenance costs.

- Which press brake is better for heavy-duty applications?

If thicker metal materials need to be bent, hydraulic press brakes are a better choice. Because of its high tonnage, it can handle thicker and heavier sheets, making it an ideal choice for heavy-duty applications.

- Which press brake requires more maintenance?

The hydraulic press brake has a more complex pump, hydraulic hose, and sealing system that requires more regular maintenance. This includes regular maintenance of the oil system, including oil replacement, filter replacement, inspection of hoses and oil cylinders, etc.