I. Introduction

As a noncontact thermal processing technology, Laser cutting technology has been an essential tool in industrial manufacturing.

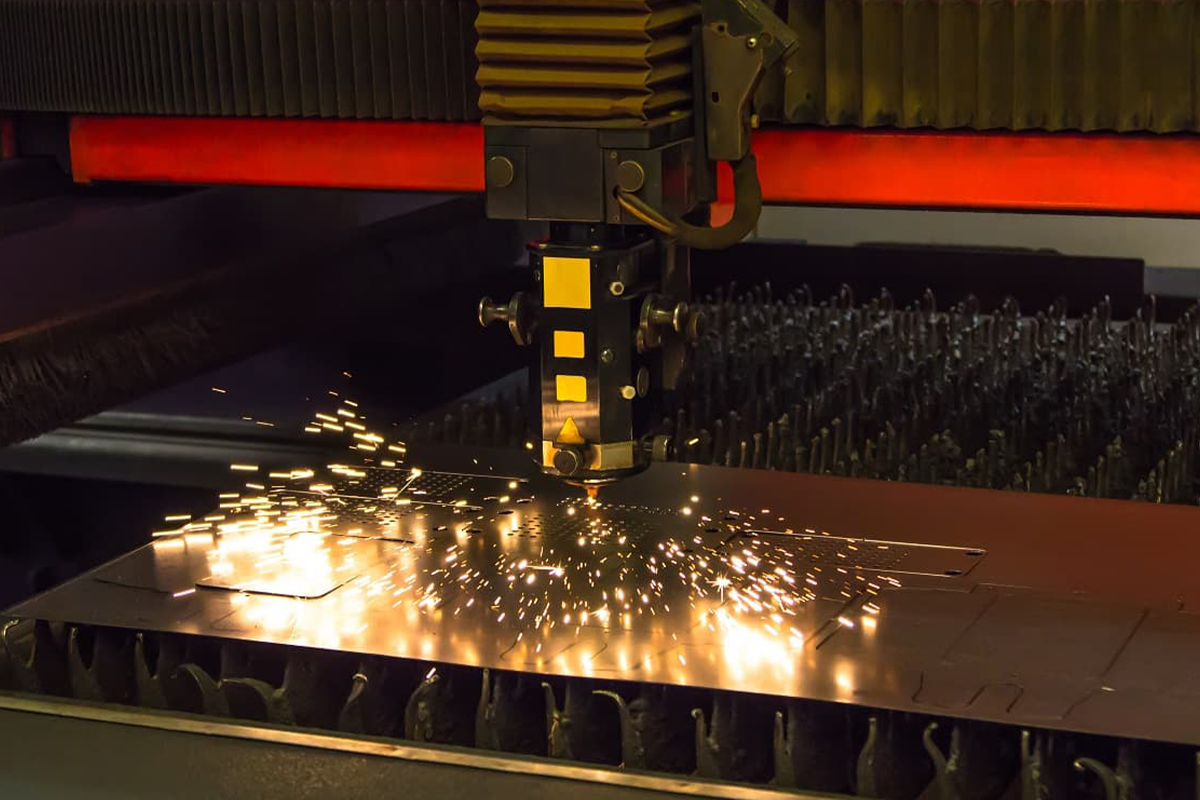

It utilizes laser beams with high power density to melt, vaporize, ablate, or ignite materials, and adopts high-speed airflow to blow away molten matter, achieving workpiece cutting.

However, any technology has its restrictions and disadvantages. Laser-cutting machines may have a bad effect on the human body.

Besides, it is of paramount importance to delve into the side effects and the safety use of the laser cutting machine, ensuring the safety and effectiveness in industrial.

II. Basics of Laser Cutting

What is Laser Cutting?

Definition and basic principles

Laser cutting is a process that irradiates the workpiece with a high-power density laser beam, making the material quickly melt, vaporize, ablate, or reach an ignition point.

Meanwhile, it is assisted by high-speed flow aligned with a light beam to blow off molten material, thus cutting the workpiece.

This technology can almost cut any material, including 2-dimensional and 3-dimensional thin metal.

The basic working principle of laser cutting involves the interaction between laser beam and workpiece, including elements like power field, thermochemical reaction, flow dynamics, and changing aerodynamics.

Brief history

The laser cutting machine's history dates back to 1964 when electrical engineer Kumar Patel first invented the gas laser cutting process using a carbon dioxide mixture at Bell Labs in New Jersey.

After that, the laser-cutting technology has been developed quickly in China.

In 1976, the CO2 laser cutting machine jointly developed by the Changchun Institute of Optics and Mechanics of the Chinese Academy of Sciences and Changchun First Automobile Manufacturing Plant Car Branch and other units successfully cut "Hongqi" car cover parts.

What’s more, fiber lasers have become the mainstream in cutting applications, and the average installed power of the market as a whole is increasing year by year.

Types

The main types of lasers are CO2, fiber, Nd: YAG. The CO2 is widely used in industry because of its high efficiency and long lifespan, especially in high-speed cutting.

Nd: YAG is chosen by high-end users due to its outstanding light beam quality and higher cutting efficiency.

Each laser has its own characteristics and application spheres, so the users should determine which types of laser can be used according to actual application demands and material properties.

Applications of Laser Cutting

Industries that benefit from laser cutting

Automobile manufacturing industry: laser cutting machines have been widely used in the automobile manufacturing industry. It is used in the processing of car doors, exhaust pipes, and other components. These parts will leave some unwanted edges or burrs, which will be difficult for the traditional manual or traditional processing to ensure precision and efficiency. Laser cutting can deal with smaller and narrow material areas, apparently reducing heat and material waste, and improving automobile components’ precision and efficiency.

Aerospace industry: this technology is applied in producing aircraft fuselage, wings, and other key parts, ensuring high-precision processing of the material and reducing the effects of mechanical stress.

Electronics and semiconductor industry: laser cutting technology can also be applied to precision machining for electronics and semiconductors. Laser cutting can achieve high-precision and tight-tolerance manufacturing, satisfying these industries’ needs for high-precision products.

Medical devices and equipment industry: laser cutting is mainly designed for high-precision cutting and manufacturing in the medical devices and equipment industry. This includes but is not limited to surgical instruments, dental equipment, medical equipment, etc.

Decorative industry: a laser cutting machine is used to cut complex patterns and graphics, such as automotive interior panels, etc. to meet the requirement for quick custom and personalized product development.

Common materials processed by laser cutting machines

Laser-cutting machines can cut different kinds of materials, including metal, plastic, wood, etc.

Also, it can cut nonmetal materials. For example, continuous laser cutting technology is mainly suitable for cutting nonmetal materials.

The advantages of laser cutting technology lie in its wide range of processing objects, small deformation, high precision, energy saving, and automation.

Compared with other cutting methods, laser cutting has higher cutting precision and accuracy, smaller heat-affected zones, and less material deformation, reducing material waste and pollution, decreasing maintenance costs, and improving operation safety.

III. Health and Safety Side Effects

Physical Hazards

Eye damage

During the processing of the laser cutting machine, due to the high concentration and monochromaticity of the laser, it may cause direct damage to the eyes.

Staring at the cutting head and observing the sparks for a long time may cause a stinging sensation in the eyes.

What’s more, laser light may form an image by focusing on the retina, thus greatly improving the energy intensity on the retina, and causing the cornea or retina of the eye damage.

Especially the infrared laser. Immediate damage to the eyes may occur due to the body's protective glare aversion response, the "blink reflex".

Skin damage

If its energy (power) is over large when the laser hits the skin, it may cause skin damage.

This damage can be repaired by tissue repair, although the function may decrease, it will not affect the overall functions and structures.

However, if the skin is exposed to prolonged exposure, it may cause burns and scarring. The laser can hurt the skin via photochemical or thermal burns.

The light beam can penetrate the epidermis and dermis according to the differences in wavelength, causing different levels of damage. For example, UV lasers can cause burns, skin cancer, and accelerated skin aging.

Respiratory Risks

Laser-cutting machines may cause damage to the respiratory tract during usage, especially when processing special metal materials, the combination of high temperature and gas will produce large amounts of dust.

Most of the smokes contain a large amount of chemical composition. Accidental inhalation can cause damage to the respiratory system.

And long term inhalation of these dust and gases can not only cause respiratory system mucosal irritation and inflammation but also lead to fibrosis of lung tissue.

That is welder's pneumoconiosis, which is often accompanied by manganese poisoning, fluorosis, and metal fume fever.

Long-term exposure to air pollution may increase the risk of respiratory system infection, asthma, bronchitis, and lung cancer, especially the child and the old, they are more likely to get hurt.

Auditory Side Effects

There is an undeniable problem that much noise will be generated during the machine working process.

The noise can not only affect hearing but also have a bad effect on the working environment. The study shows long-term exposure to high noise will leave deep influences on people’s hearing and health.

Generally speaking, once the noise exceeds 85-90 decibels, it will damage the cochlea. When the voice volume updates to 100 decibels, long-term exposure will cause irreversible hearing loss.

IV. Environmental and Mechanical Impacts

Air Quality Concerns

There is much dust and fumes during the laser cutting process. This dust may include poisonous substances, such as heavy metals and organic compounds.

The dust will pollute the surrounding air and water if the emission is not effectively controlled. Besides, smoke and harmful gases generated from laser cutting are in the form of air, and flow in the workshop, and will threaten to workers’ health if it is not effectively controlled.

Material Waste and Efficiency

Material waste is an undeniable problem during the laser-cutting process. In traditional cutting, a large amount of material will be wasted because of the large cutting gap and long distance.

However, laser cutting technology can effectively decrease material waste by optimizing part arrangement and using tools like Fabricaide.

Energy Consumption

The main energy-consuming parts of the laser cutting machine are the machine tool host, water cooler, dust removal device, etc.

V. Operational Hazards

Equipment Malfunctions

Doesn’t return to origin when turned on. Cut the circle is not round. "Exceeding limit data error" appears on the panel display. The high-pressure headwater pipe of the laser tube leaked and ignited.

Precaution maintenance

Precaution maintenance is an important way to prevent equipment malfunction, including regular checking, maintenance, repairing, and helping equipment run normally.

The execution of preventive maintenance requires careful planning and scheduling, including scheduling a maintenance plan, checking the equipment regularly, and maintaining and repairing equipment.

Besides, it is also paramount to record the equipment checking and maintenance report, so that the operation states of the equipment can be tracked and managed.

Safety checking

Apart from precautious maintenance, regular safety checking is also indispensable. This includes checking the electricity system, and hydraulic system of the laser cutting machine, ensuring all the connections are stable and reliable, with no loose or damaged parts.

At the same time, adequate precautious measurements should be taken to check the equipment, such as baffles to prevent cutting sparks from flying, etc.

Fire Risk

Although the laser cutting machine uses a low-risk laser, it also can cause a fire because of dirt and debris.

Once the fire occurs, the measurements should be taken: if the fire is small, the fire can be put out by a fire extinguisher.

Before starting to put out the fire, the power supply should be cut off. If the fire is big, seek help through the nearest siren, move quickly to the nearest exit, and notify and assist others to evacuate along the way.

Not to take the elevator, close the door to the fire area and surrounding to control the fire and smoke, but not to lock the door.

Operator Error and Training

The improper operation of the operator may cause accidents. So regular technology updating and training courses are necessary, helping workers better adapt to the working environment and effectively prevent safety risks.

VI. Mitigating Side Effects

Safety Equipment and Protocols

Safety equipment is paramount, including laser protective goggles, protective eye masks, protective clothes, etc., which can effectively protect your eyes, skin, and hands from laser radiation and splash materials.

Also, specific safety procedures should be obeyed, like prohibiting smoking in the cutting area, especially near the oxygen cylinder.

Besides, many fire extinguishers and other safety equipment levels should be used. It is also necessary to choose a reputable supplier’s machine, ensuring it fits the FDA regulations.

Training and Awareness

Offering constant safety education sources is of vital importance. This may include but is not limited to theory training, safety operation procedures, operation techniques and precautions, safety and maintenance knowledge, and eye protection.

Technological Advances

Laser cutting technology has achieved apparent progress during the past years, especially the development of super high power fiber laser cutting technology, which can quickly achieve fast and high-quality thick sheet cutting, and use the air as assistant gas to cut.

At the same time, the use of the flat laser cutting machine also brings positive side effects of reducing waste and improving the utilization rate of remaining materials.

Besides, laser cutting is applied in the bloodless incision, minimally invasive surgery, which can reduce the surgery risk, but also improve the surgery efficiency.

With the fast development of technology, laser-cutting machines will gradually develop into automatic and intelligent orientations.

VII. Conclusion

Although the laser cutting machine weighs a lot in improving production efficiency, it can’t be denied that it causes potential damage to the human body.

Therefore, it is of pivotal importance to strengthen safety awareness, take effective protection measurements, and constantly take technology innovations.

Through these endeavors, we can reduce the effect of laser cutting on the human body, and promote the healthy development of laser cutting technology.

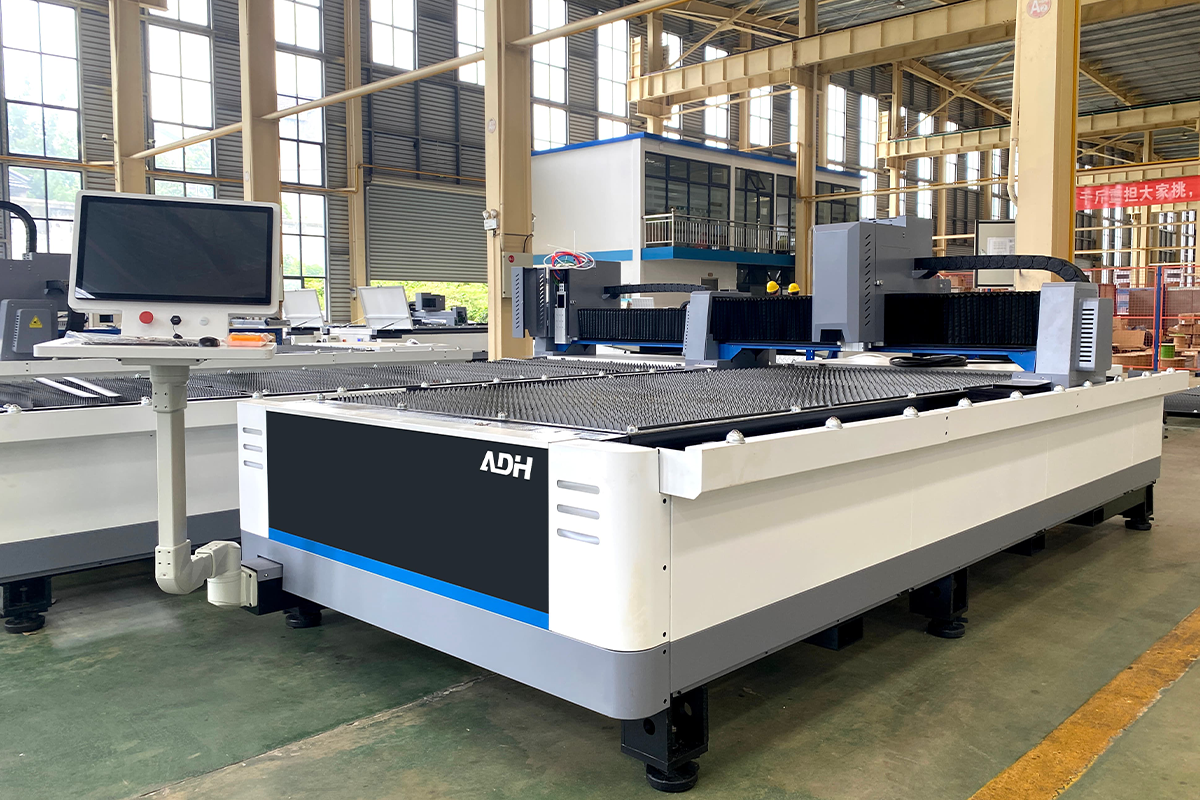

ADH Machine Tool is a specialized company for producing laser cutting machines, and we are ready to offer help to you. you can browse our official website or seek help from our professional salesman.