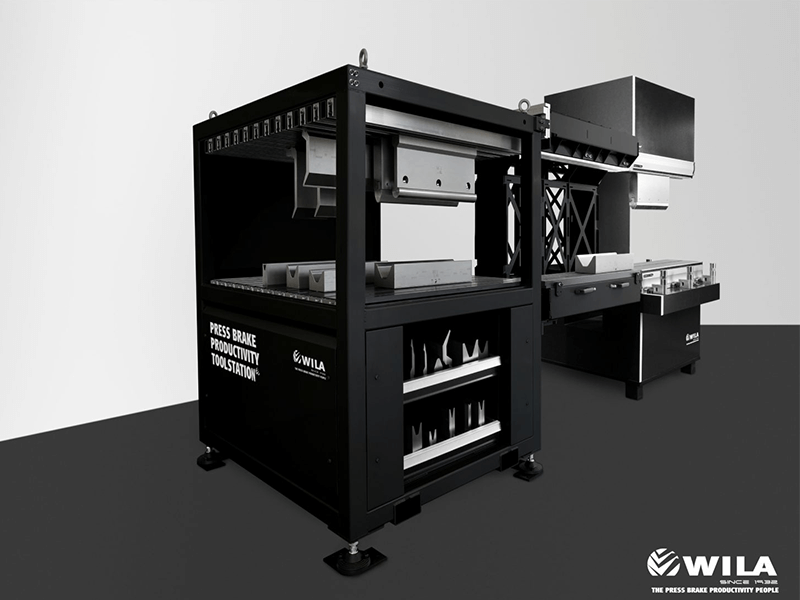

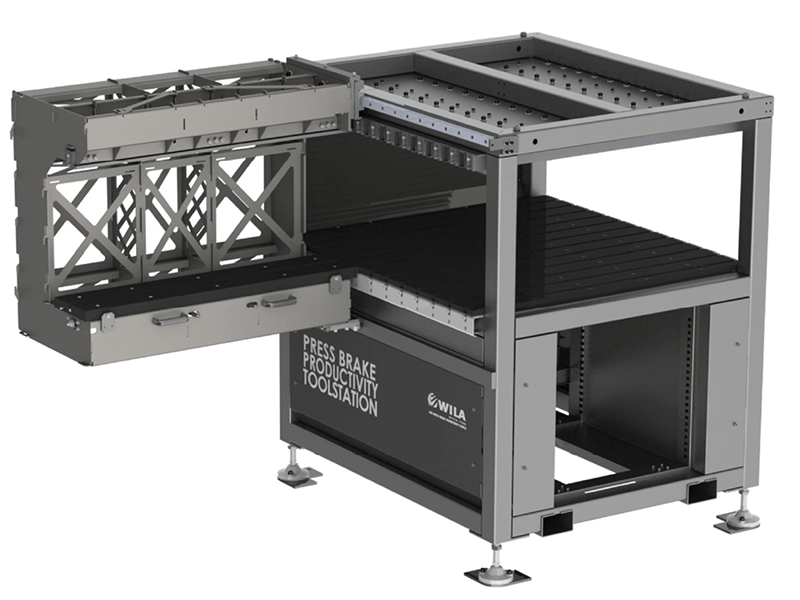

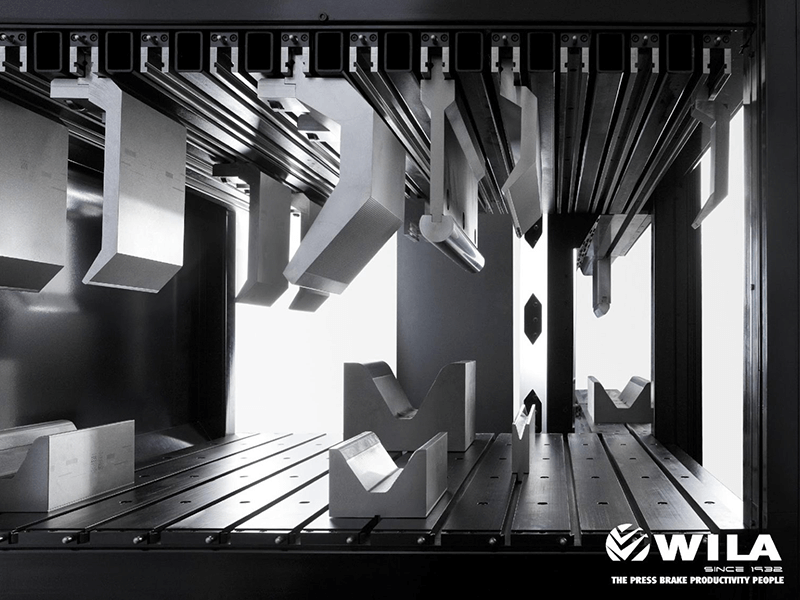

ADH offers two versions of the

Press Brake Productivity Tool Station, which are specifically designed for the secure exchange and storage of WILA tooling. The first version, the 'HD' version, is developed to accommodate very large and heavy tools and is compatible with the NSCL-HD-II-HC Heavy Duty Clamping system. The second version is suitable for smaller tools and works seamlessly with the WILA Premium Clamping system. Both versions of the Tool Station are engineered to ensure safe and efficient tool storage and exchange, thereby promoting enhanced productivity and optimized workflow in press brake operations.