| Model | FPC |

|---|---|

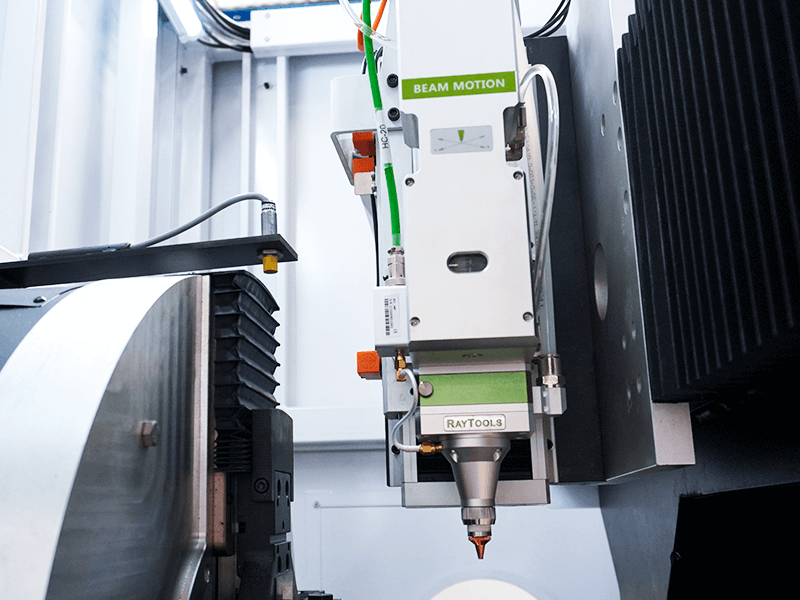

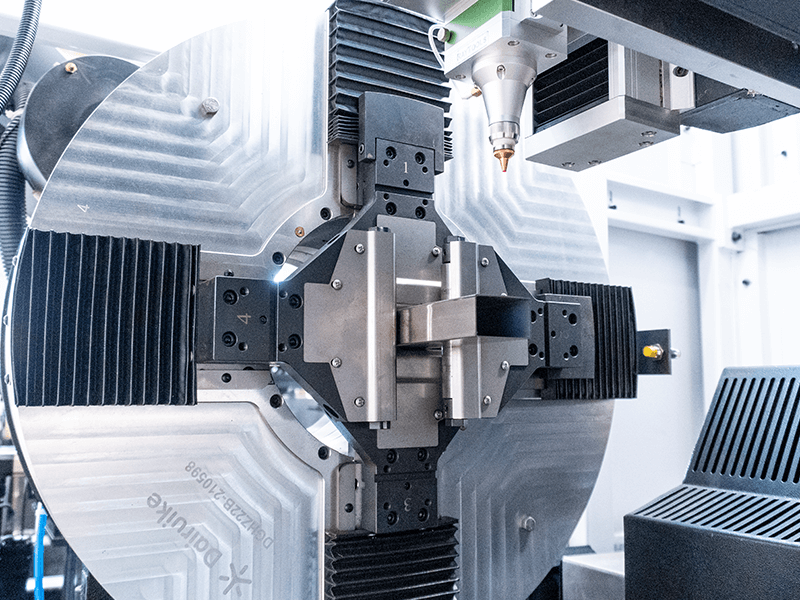

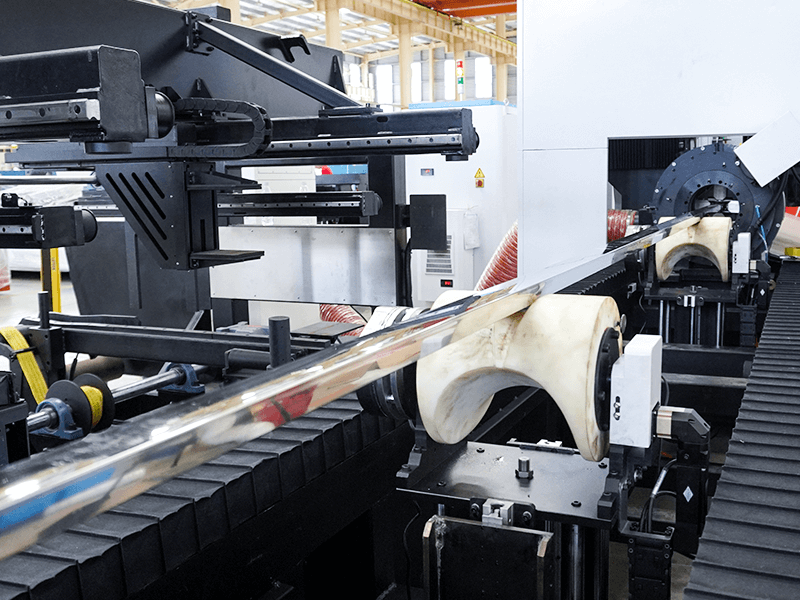

| Pipe Dimensions | Diameter: 20mm-200mm Length: 6m/9m (320mm Optional) |

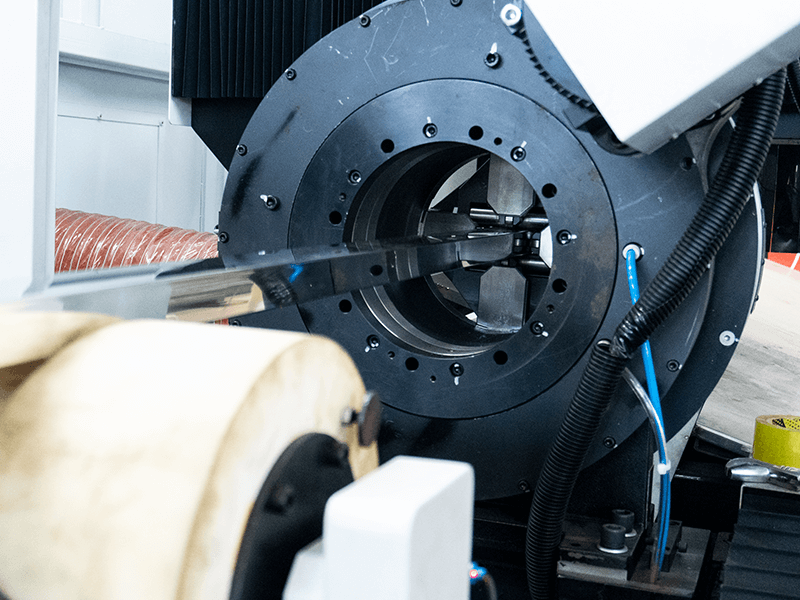

| Tube Category | Round,Square,Oval,Rectangular,Triangle,ect. |

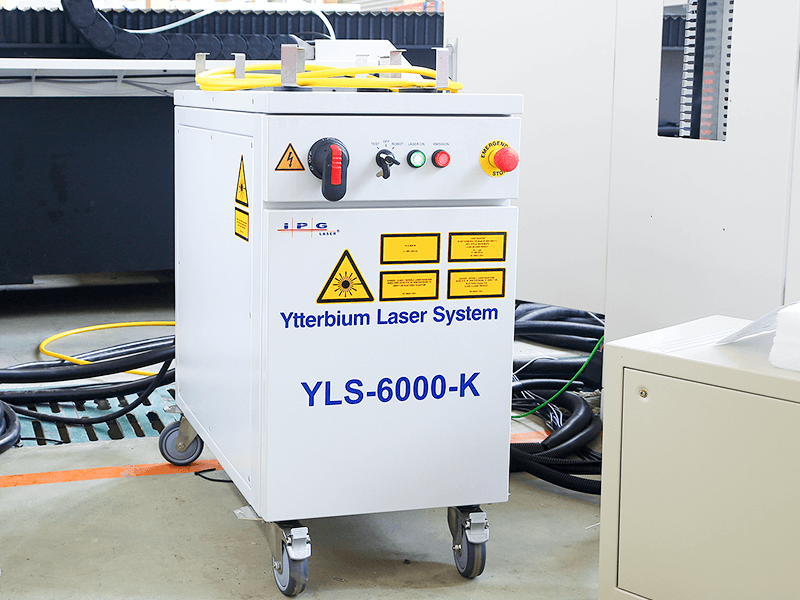

| Laser Power | 1000W-6000W |

| Max. Acceleration | 0.8G |

| Rotary Speed | 80r/min |

| Positioning Accuracy | ±0.05mm |

| Repositioning Accuracy | ±0.05mm |

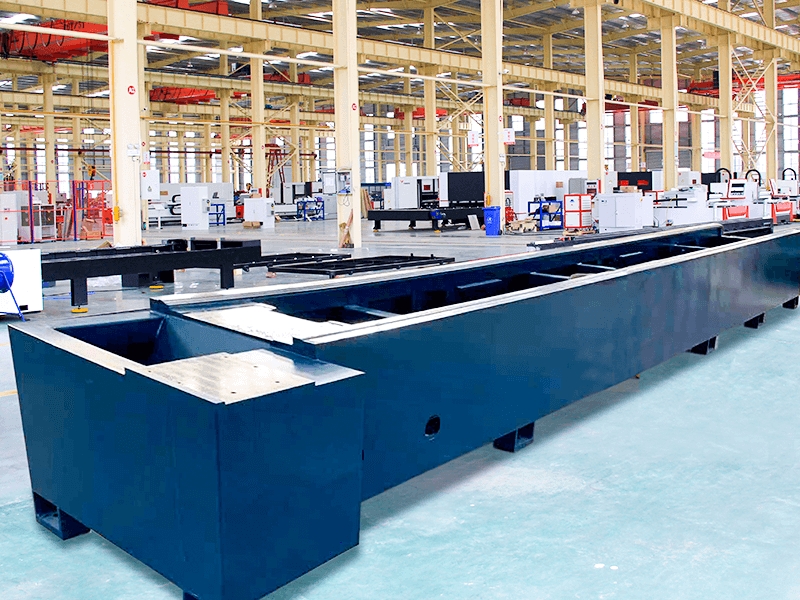

| Total Weight | Over 13T |

| Total Power Consumption | 18.3KVA-41KVA |

| Power Supply | 380V50Hz/380V60Hz/220V60Hz |

| Dimensions | 12246*5388*2355mm |