| Model | 3200/1250 | 3200/1500 | 4000/1250 | 4000/1500 |

|---|---|---|---|---|

| Max grooving width (mm) | 1250 | 1500 | 1250 | 1500 |

| Max grooving length (mm) | 3200 | 3200 | 4000 | 4000 |

| Max grooving hight (The flatness of stainless steel sheet is less than 3mm) (mm) | 6 | 6 | 6 | 6 |

| Min grooving thickness (mm) | 0.4 | 0.4 | 0.4 | 0.4 |

| Min distance between V-groove and edge (mm) | 8 | 8 | 8 | 8 |

| Max cutting speed m/min | 0-90 | 0-90 | 0-90 | 0-90 |

| Return speed | 0-120 | 0-120 | 0-120 | 0-120 |

| Left and right movement resolution of tool rest (mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| Positioning accuracy (mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Up and down movement resolution of tool rest (mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| Positioning accuracy (mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

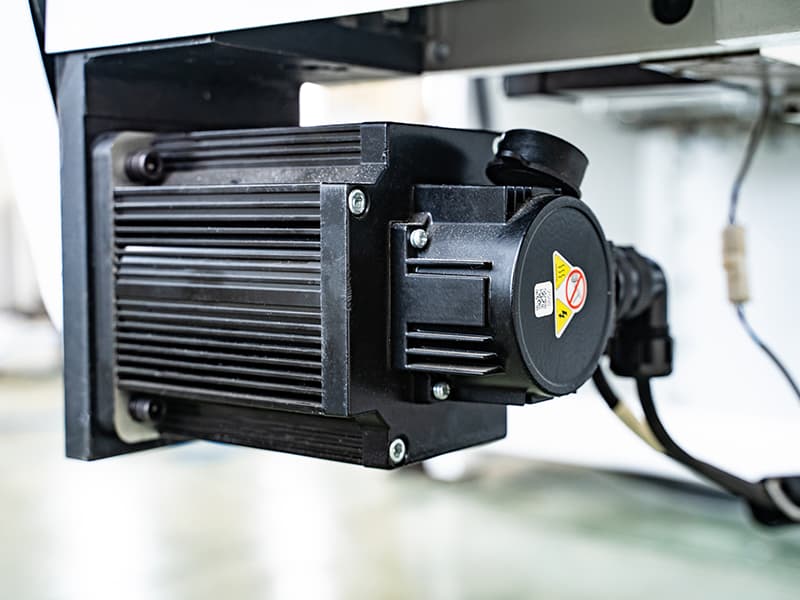

| Power of main servo motor (kw) | 4.5 | 4.5 | 4.5 | 4.5 |

| Hydraulic system working pressure (Mpa) | 6-8 | 6-8 | 6-8 | 6-8 |

| Machine size (L*W*H) | 4800*2650*2100 | 4800*2850*2100 | 5850*2650*2100 | 5850*2850*2100 |