I. Introduction

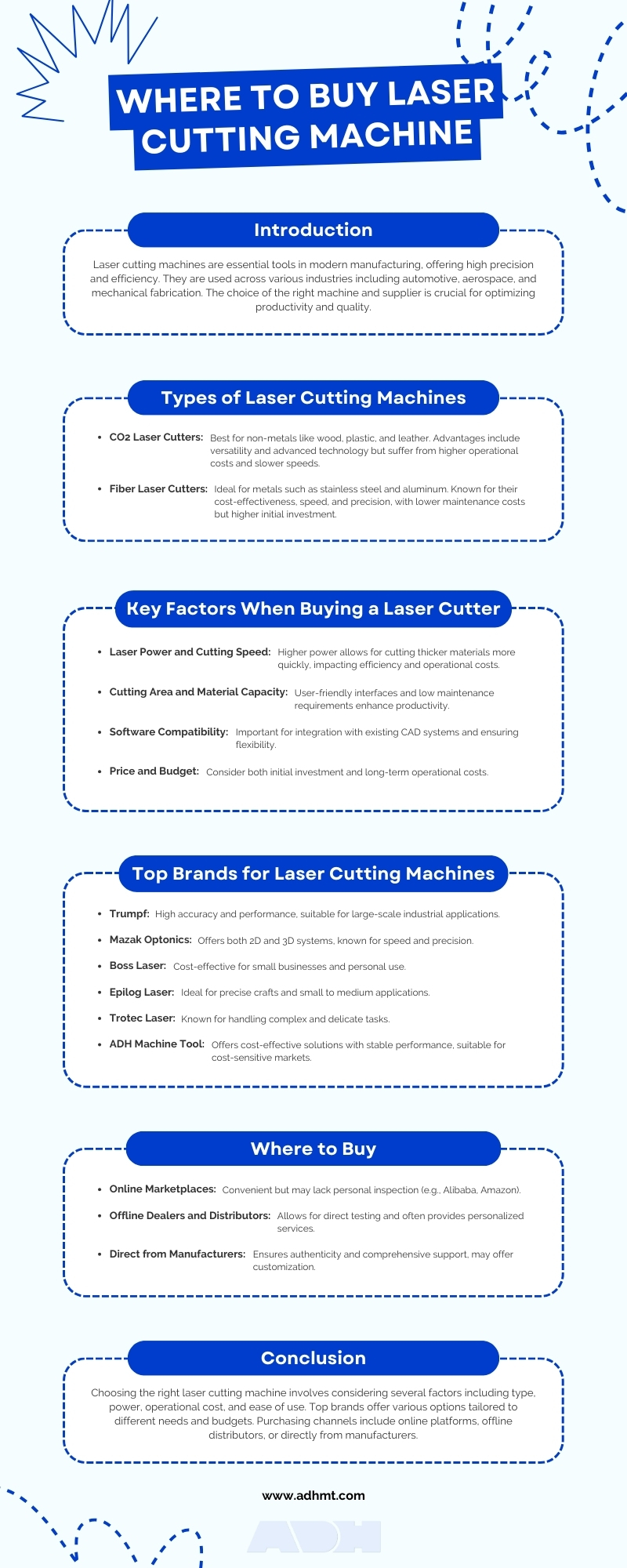

In nowadays’ manufacturing, laser cutting machines serve as the crucial production tool by virtue of their excellent quality for accuracy and efficiency. These magical machines utilize laser cutting technology to cut multiple materials, including metal, plastic, glass, wood, and composite materials.

The machine has not only improved productivity, but ensured processing quality, enabling complicated designs so that they are favoured by many sectors, especially for manufacturing. At present, laser cutting machines have been applied in automotive, aerospace and mechanical fabrication industries.

What I mean is that choosing the right laser cutting machines is really crucial for your company and business. Because the right laser-cutting machine is of significant importance for ensuring productivity and product quality. However, various demands for material processing entail different laser cutting machines.

For example, CO2 laser cutting machines are suitable for non-metal cutting, while fiber laser cutting machines are for all kinds of metals. Therefore, choosing an appropriate machine based on materials and other matter factors can boost processing speed and accuracy so as to reduce production costs.

When it comes to buying, we all know that a reliable supplier matters. Premium suppliers can not only provide high-end and -performance laser cutting machines but also necessary technology support and services so as to ensure long-term stable operation. The technical support incorporates installation, adjustment, training and maintenance, which play an essential role in stabilizing operation and prolonging lifespan.

It’s obvious that laser cutting machines are indispensable in nowadays’ manufacturing. Their strengths on accuracy and efficiency improve company’s competition. Therefore, an appropriate laser cutting machine and reliable suppliers are decisive decision for any enterprise seeking high quality and efficiency.

Are you considering buying laser cutting machines and don’t know what factors to consider and where to buy? Don’t worry; in the article, I will provide you with a thorough guide about Where to Buy the Best Laser Cutting Machines in 2024.

II. Most Competitive Types of Laser Cutting Machines

In the present metal processing sector, laser cutting machines distinguish themselves by strength in accuracy and precision and have become popular in the market. There are mainly two types of laser cutters that dominate the market: CO2 laser cutting machines and fiber laser cutting machines. Today, I am going to introduce the two kinds of machines in detail and compare their difference so as to help you acquire a deeper understanding of these machines.

CO2 laser cutters

CO2 laser cutting machines utilize CO2 laser sources and generate a laser with a wavelength of 10.6 micrometres. This kind of laser is well-absorbed by non-metals so they are suitable for cutting wood, acrylic, plastic, paper, leather and fabric and other non-metals. The advantages of CO2 laser cutting machines lie in their advanced cutting technology, wide application and compatibility with multiple materials which include some metals.

However, their weaknesses are also apparent, such as high operation and maintenance costs and low speed and efficiency.

Fiber laser cutters

Fiber laser cutting machines utilize solid laser sources with a wavelength of about 1.06 micrometres. This kind of laser can be well-absorbed by metals so they are more suitable for metal cutting, such as stainless steel, carbon steel, copper and aluminiun. Their advantages lie in high cost-effectiveness, speed and accuracy and low operation and maintenance costs. Their weaknesses are the high initial investments and incompatibility with non-metals. Let’s enjoy a video to learn about this magic machine.

Comparison of CO2 and Fiber Laser Cutting Machines

When comparing these two kinds of laser cutting machines, we can start with the following aspects:

Cutting material: CO2 laser cutting machines can deal with all kinds of non-metals, while fiber laser cutting machines perform better in metal cutting.

Operation costs: Fiber laser cutting machines’ operation costs are less than CO2 laser cutting machine because their high light-electricity trasformation rate and low energy consumption.

Cutting speed and accuracy: Fiber laser cutting machine cut faster and more accurate than that of CO2 laser cutting machine when handling thin metal boards.

Maintenance costs: CO2 laser cutting machines require regular maintenance of their optical systems, while fiber laser cutting machines require almost no maintenance and have lower maintenance costs.

Generally, which one to choose is based on users’ demands. If the customer plans to cut non-metal materials or has low requirements on metal cutting speed, CO2 laser cutting machines might be a more economic choice. However, if a customer seeks high-speed and accuracy cutting for metals, fiber laser cutting machine is definitely an intelligent selection.

But no matter what type of laser cutting machine you choose, efficient and accurate cutting will be provided to improve productivity and product quality.

III. Factors to Consider When Buying a Laser Cutter

If you are considering where to buy laser cutting machines, you should learn what factors to consider first. I think I can offer you some suggestions. When buying, there are actually some important factors that affect the performance of laser cutting machines.

Therefore, to ensure the most valuable investment and production ratio and meet production demands, I listed some pivotal elements as follows:

Laser power and cutting speed

Laser power is one of the decisive elements that effects laser cutters performance. Basically, we can say that the higher the power, the stronger the cutting strength. So, they are capable of cutting thicher materials in faster speeds.

For example, a laser cutter with higher power can ensure high-quality cutting even when it increases cutting speed and handles thicker materials. Therefore, suitable laser cutting power is related to cutting efficiency and operation costs because high-power laser cutting machines entail higher costs.

Cutting area and material capacity

The cutting area decides the maximum size of the materials that can be handled by the machines. Selection of suitable cutting area based on your demands is critical, that’s because too small cutting areas maynot meet the demands of large materials processing.

In addition, another element you should notice is that material capacity affects the categories of materials that can be processed. These materials include metal, plastic, wood and so on, and different laser cutting machines can meet different materials’ demands.

Ease of use and maintenance

Ease of use for a laser cutting machine can significantly improve productivity. Modern laser cutting machines are equipped with advanced CNC control system and user-friendly sreen which facilitate operation.

Besides, ease of maintenance is also an important matters. Some high-end laser cutting machines entail low maintenance demands, significantly lowering operation costs.

Software compatibility

Laser-cutting machines’ software compatibility affects their flexibility and scalability. The selection of a laser cutting machine that is compatible with multiple CAD and pattern designs can ensure that the machine can be seamlessly integrated into the existing design and production processes.

By the way, I want to remind you that the updation and technology support are also the key factors toensure long-term machine operation.

Price and budget

The prices of laser cutting machines vary from thousands of dollars to hundreds of thousands of dollars. It mostly depends on the performance, size and function of the machine. When you are considering budget, initial investment and long-term operation and maintenance costs should be taken into account.

Although high-end laser cutting machines have higher initial costs, their high efficiency of operation and low maintenance costs could save more in the long run.

Based on what I have introduced to you, it’s obvious that the purchasing of a laser cutting machine needs to take many aspects into consideration. Understanding and estimating these key factors can help you choose the most suitable laser cutting machine which can not only meet your production demands but also deliver the best price performance.

Considering the elements I listed above for you carefully, you can bring a highly efficient, economical and reliable laser cutting machine home.

IV. Top Laser Cutting Machine Brands to Choose

Having considered what factors matter, we are now going to discuss where to buy our machines. I believe most of us will first think of brands that provide us with reliable machines. It’s out of the question that no matter whether you are an individual buyer or an enterprise, machines of famous global brands are your top choice.

Therefore, today, I have selected some brands with reputations from different countries, including Trumpf、Mazak Optonics、Boss Laser、Epilog Laser、Trotec Laser and ADH Machine Toolso as to offer you as reference. The following will detail the characteristics of these brands and make comparisons.

Trumpf

Established in 1923, Trumpf, a family-owned company in Germany, is one of the leaders in industrial machine and laser cutting machine manufacturing. Trumpf’s laser cutters are famous for high accuracy, excellent performance, and technology invention.

The company provide customers with many types of laser cutting machines, including CO2 laser cutters, solid laser cutters and fiber laser cutters. They can meet various processing demands. Trumpf also emphasizes smart factories and provides Industry 4.0 solutions, offering digitally connected production processes.

Mazak Optonics

Mazak Optonics is part of the Japanese Yamazaki Mazak Corporation, specializing in laser technology. Mazak can provide laser cutting machines with different configurations, including 2D and 3D laser cutting systems. On strengths of high speed and precision and brand reliability, Mazak’s machines are favoured by customers for industrial use. At present, Mazak‘s laser cutting machines are widely applied in automotive, aerospace and heavy industries.

Boss Laser

Boss Laser is a 100% US company and a manufacturer of laser cutting machines which provide users with multiple types of laser cutting machines and engraving machines. With reasonable prices, Boss Laser’s machines are especially suitable for small businesses and personal users. Being capable of handling all kinds of materials, including wood, plastic, glass and metal, its machine is an intelligent choice for creative crafts and small-scale production.

Epilog Laser

Home to the United States, Epilog Laser is an enterprise that focuses on small and medium laser cutting machines and engraving machines manufacturing. By virtue of its user-friendly screen and high-precise cutting, Epilog Laser’s machines are especially suitable for gifts and prototype designs that seek precise crafts and personality.

Trotec Laser

Austria's Trotec Laser offers high-speed, high-precision laser cutting machines suitable for a wide range of materials and applications. Trotec's devices are renowned for their innovative design and excellent performance, especially when handling complex and delicate cutting tasks.

ADH Machine Tool

As one of China’s top 5 Mechanical Manufacturers, ADH Machine Tool provides all kinds of industrial machines, including laser cutting machines. ADH's laser cutting machines are welcomed in the market for their cost-effectiveness and stable performance, making them suitable for cost-sensitive markets.

The company boasts 4 decades of laser cutting machine R&D history, professional operators and a renowned brand. If you don’t want to invest too much initially but seek for high precision, quality and efficieny. Its laser cutting machine will never disappointed you.

Comparison

| Technology &innovation | Cost&revenue | user friendly | industrial use | business scale | |

| Trumpf | ✔ | ✔ | large | ||

| Mazak Optonics | ✔ | large, medium | |||

| Boss Laser | ✔ | ✔ | small | ||

| Epilog Laser | ✔ | small, medium | |||

| Trotec Laser | ✔ | small, medium | |||

| ADH Machine Tool | ✔ | ✔ | ✔ | small, medium |

Choosing the right laser cutting machine brand requires decisions based on specific application needs, budget, and operational convenience. Each brand has its unique advantages, suitable for different markets and user requirements.

V. Where to Buy Laser Cutting Machines

There are many channels to buy laser cutting machines, each way has its own pros and cons. Generally, there are three main channels: online marketplaces, offline dealers and distributors and buying directly from manufacturers.

Online marketplaces

The major strengths of online marketplaces are convenience and fast purchase. It’s convenient for customers to compare different brands, types, functions and prices of laser cutting machines. What’s more, the preview of users’ reviews can help customers to understand the performance of each machine.

However, this channel also has disadvantages. Sometimes, customers may be unable to check the quality and operation of the machine in person, and its after-sale services may not be provided in time, just like those of offline dealers and distributors.

Top Online Supplier:

There are some well-known online platforms I listed for you, such as Alibaba, Amazon, and eBay. Some brands also have their own websites. For example, ADH Machine Tool sells its products on the official website. These platforms gather all kinds of brands and suppliers, making it easier for customers to compare and select.

Offline dealers and distributors

When purchasing laser cutting machines, you can directly check the machines through offline dealers and distributors and test the function and performance of the machine on the spot. Besides, local distributors can normally provide more personalized services and technology support for customers, which are of critical importance for machine installation and maintenance and repair.

When choosing a reputable dealer, one can refer to customer reviews, recommendations within the industry, and whether professional after-sales service is provided. Attending industry exhibitions and visiting manufacturers' official websites usually helps in finding a list of certified dealers.

Take ADH as an example, the company located at Xinshi Industrial Zone, Bowang District, Ma'anshan, China has its own campus for laser cutting machines. If you are interested in the company, you are welcome to have a visit.

Buying directly from manufacturers

Buying directly from manufacturers can ensure that these machines are genuine. Customers can also benefit from comprehensive technology support and after-sale services.

In addition, in many cases, manufacturers will provide customized services so as to meet other special demands. However, the costs of this channel may be higher, and the purchase procedures may be more complicated.

Leading laser cutting machine manufacturer:

Some top laser cutting machine manufacturers, including Trumpf, Mazak Optonics, and ADH Machine Tool, not only provide high-quality machines but also offer a global sales and service network to make sure customers receive timely technical support and machine maintenance.

Overall, many channels are accessible for customers to buy laser cutting machines, each with its own pros and cons. That’s why the article was written to serve as a reference for anyone distressed about where to buy a laser-cutting machine.

VII. Conclusion

In the article, I introduce the factors to affect the performance of a laser cutting machine, the top laser cutting machine brands to choose and some channels that might be helpful and reliable for buying a laser cutting machine.

ADH Machine Tool, one of the most reliable Chinese brands, can provide you with high-quality, efficient, accurate, and reliable products. What’s more, timely after-sale services and machine maintenance can reduce your long-term operation costs. It’s an intelligent choice for you.

You can also view our product page first. If there are any questions, you are welcom to contact us.