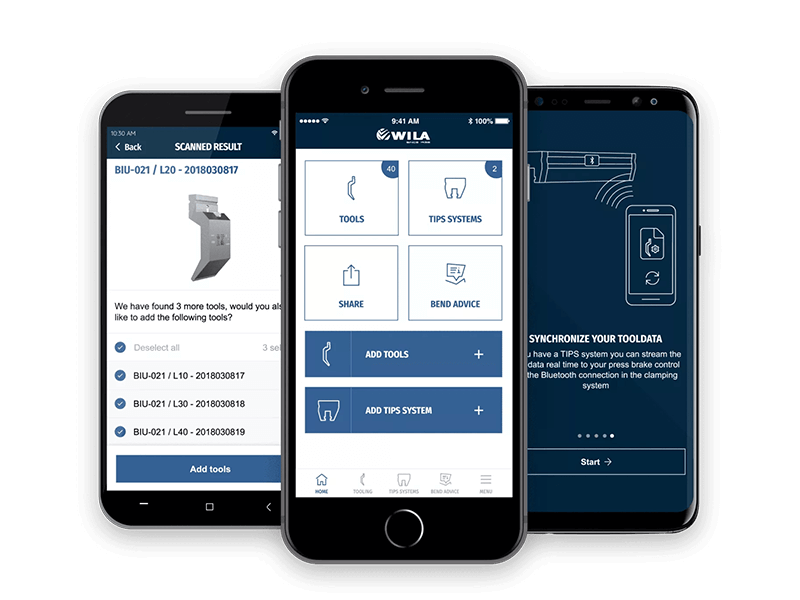

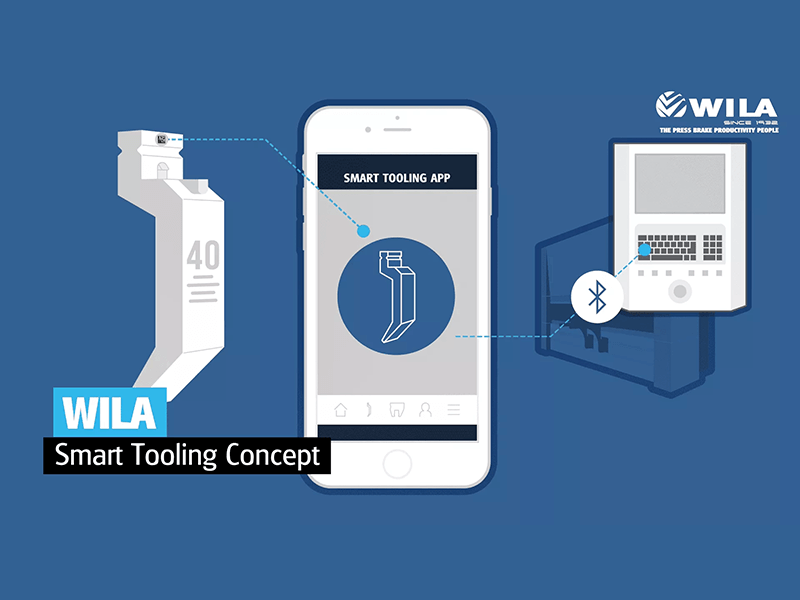

WILA has launched a new smartphone application, the Smart Tooling App, which provides tool management solutions for press brake tools. This innovative app enables WILA customers to experience the benefits of digitalization and data connectivity, including easy access to tool data anytime, anywhere, significant time savings, error-free tool data entry, and simplified stock management.

All of WILA's New Standard Premium tools are equipped with a unique DM-code, and with the Smart Tooling App, users can effortlessly scan all tools at once using the DM-code on the box or scan each tool individually. After scanning the DM-code, users can immediately access the tool's specifications and the correct tool data files for their

press brake control. Furthermore, they can easily share the tool data directly to their cloud and add the tool files to their press brake control for seamless integration.