After a sheet metal is bent, its actual size may differ from the size depicted on its flat pattern drawing.

This is due to the external tension that stretches the sheet and internal compression caused by extrusion.

The total flat length increases, so it's essential to calculate the bend deduction.

Bend deduction is the difference between the total flange length after bending and the total flat length.

In a previous article, we discussed the calculation of bend allowance and bend deduction.

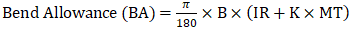

Bend allowance calculation formula:

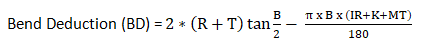

Bend deduction calculation formula:

This calculation formula is used to determine the flat pattern length of sheet metal and the size of the workpiece.

The bending chart provides an intuitive way to visualize the effect of different parameters such as bend angle, radius, material thickness, etc.

For instance, if the bend angle is known to be 90 degrees, you can refer to the 90-degree bend deduction chart to find the desired parameters.

Conclusion

The value of bend deduction can be calculated not only through a formula but also using a deduction chart.

To gain further knowledge about sheet metal bending, you can explore the ADH website blog for more informative content and products.

The press brake of ADH has high performance and efficiency. If you need more information, you can contact our product experts.

FAQs

What Is Bend Deduction and Bend Allowance?