The maintenance of the press brake helps to prolong the service life and reduce the cost.

The maintenance of the press brake is mainly divided into several parts, including the hydraulic system, mechanical parts, lubrication, electrical equipment, and tooling.

Daily maintenance of the press brake is trivial but relatively simple. Once the daily overview procedures are done, it's time to tackle specific maintenance tasks.

Importance of Regular Maintenance

The importance of regular maintenance cannot be overstated.

As we all know, the press brake's service life depends on the product's quality, but it also depends on the user's maintenance measures.

Regular maintenance is not only necessary to prolong the service life of the press brake, but it can also eliminate faults and reduce the workpiece damage rate, as well as the potential danger to operators.

A detailed periodic maintenance plan should be developed and documented in a form. Both press brake operators and maintenance personnel need a professional training.

Regular maintenance can detect faults in the press brake in time and avoid expensive maintenance costs.

This article will introduce several important aspects of press brake maintenance.

Overall Inspection

Before using the press brake, check the machine's overall condition.

Check for any residues on the tooling areas and workbench.

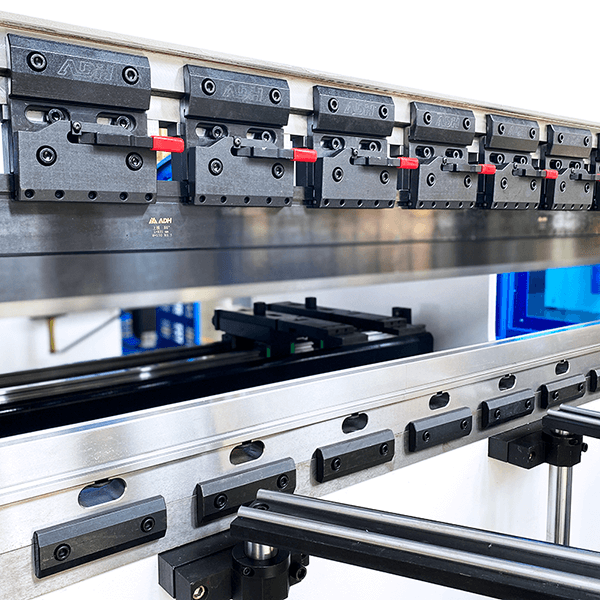

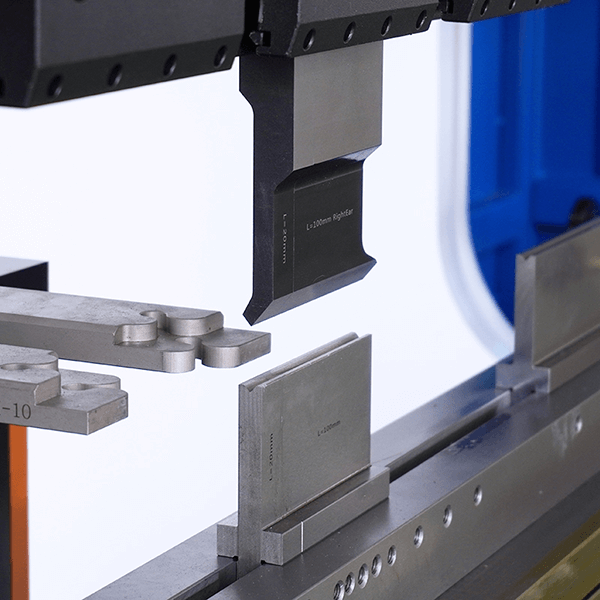

Check the condition of the upper and lower dies for defects and cracks.

If the dies have cracks, they can affect the bending quality of the workpieces.

Test the accuracy of the back gauge and the stop finger's position.

Also, test whether all buttons, switches, indicator lights, and foot controls are sensitive.

These can be routine inspection items before each use of the press brake.

Additionally, some important parts require special maintenance.

Hydraulic Circuit

Hydraulic oil is the energy source of the hydraulic system.

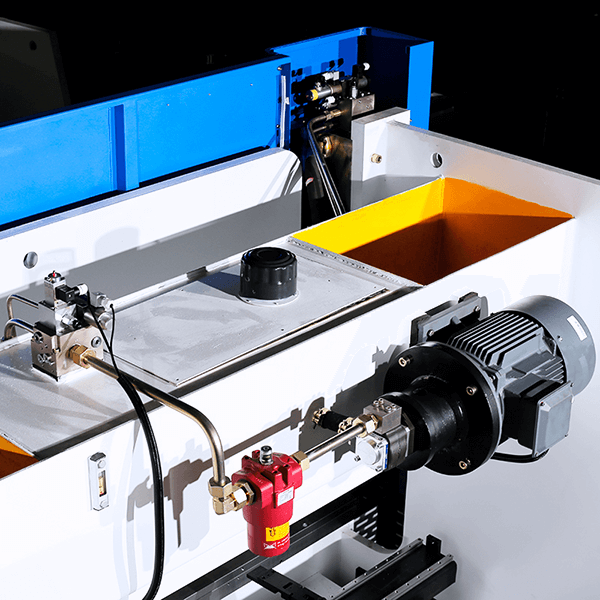

It is important to keep the oil and hydraulic circuits clean. The hydraulic circuit includes the oil tank, valve group, pipeline, motor, oil pump, etc.

It is not recommended to use detergents when cleaning valves, oil tank covers, and related accessories.

Also, visually check whether the oil level in the oil tank is within the safe range every day.

Otherwise, the operation of the hydraulic pump will be affected, resulting in insufficient power to drive the ram.

Make sure that the oil tank is properly sealed and ventilated.

However, the oil tank cannot be completely sealed, and breathers are required to prevent the oil tank from generating a vacuum.

The seal is designed to prevent particles from entering the tank and contaminating the oil.

The contaminated oil can block the valve and damage the hydraulic pump, thus affecting the operation of the hydraulic system.

Hydraulic fittings

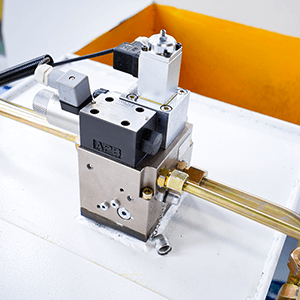

Check all pipes and hoses for leaks, especially the hydraulic pump and connecting accessories.

In case of expansion of oil hoses, aging, or wear of pipelines, they should be replaced promptly.

Check the cylinder assembly, valves, and hydraulic block for leaks.

If there is too much oil on the piston, wipe it clean and apply proper lubrication.

Check the maximum pressure of the pump and relief valve.

Clean the oil tank and filters

Before replenishing the oil, it is necessary to clean the oil tank and filter.

The filters of the oil inlet and outlet holes of the oil pump should be cleaned, and the air breathers on the oil tank need to be cleaned with compressed air.

The filter and air breathers need to be replaced after a certain service life.

The oil temperature should not exceed 60 degrees as it can affect the stability of the oil and damage the accessories.

The cleanness and level of the oil

Use the oil type recommended by the manufacturers to ensure the cleanliness of the oil.

Check the oil level in the oil tank every day and use an electric pump to fill the oil.

The quality and viscosity of the oil should be checked every 4000 to 6000 hours of operation.

Mechanical Components

Regular inspection of the mechanical components is necessary to ensure the stability of all parts.

It's important to tighten all bolts, nuts, and screws regularly and check the connection between the piston and the ram.

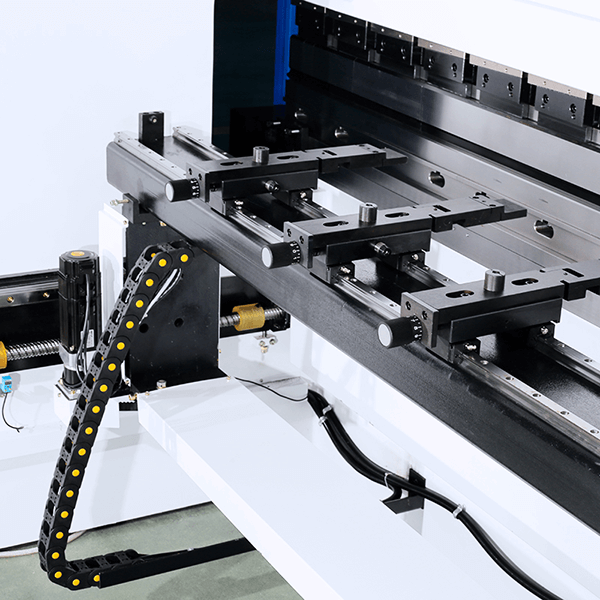

Inspect the base's connecting part for any cracks and examine the back gauge and stop finger's condition. Recalibration is necessary if required.

Lubrication System

The lubrication of press brake parts is an important factor in prolonging the machine's service life.

Some parts of the press brake are subject to sliding, rolling, or friction.

Lubrication can reduce friction and damage to components.

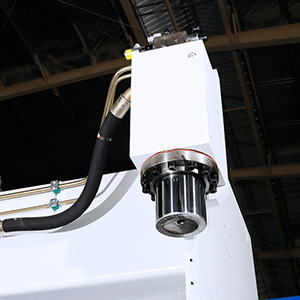

Parts requiring regular lubrication and cleaning include the ball screw, guide rail, back gauge, gear, etc.

These should be lubricated at least once a week, and some parts may even need to be lubricated every day.

However, it's important not to over-lubricate, as this can cause insufficient friction or component contamination.

Before applying lubricant or grease, make sure to clean all components and use the lubricating products recommended by the manufacturer.

Electrical Equipment

The maintenance of electrical equipment is a top priority to prolong the service life of the press brake.

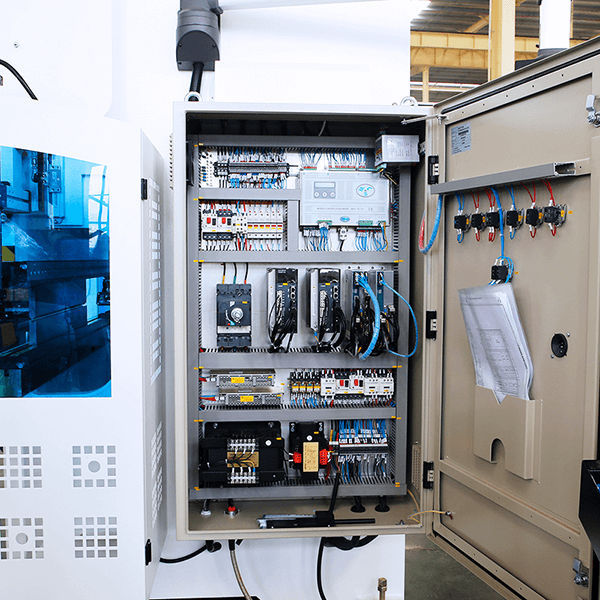

Check the entire electrical system at least once a year, including all electrical connections and switches.

Before the inspection, it is necessary to turn off the main power switch. Other inspections can be carried out after the power is on.

Keep the components in a clean and safe condition when assembling electrical components.

Check the connection status of the terminal boxes and terminal strips on the monitor and relay.

Check whether all wires are loose, whether insulation is damaged, and whether the wires are clean and orderly.

If the wires are loose, tighten them and clean them with a clean cloth or compressed air.

Check the air filter of the electrical cabinet and inverter box and clean it with compressed air.

Check all cables, printed circuit boards, and switches. If there is damage or a fault, repair and replace them.

Check whether the limit switches and voltage are in good condition.

Keep the cooling fan and heat exchanger filter clean and in normal operation.

Check whether the external panel of the electrical box is turned off and whether the switches, lights, and other functions work normally.

Tooling System

A press brake is a machine used to bend different sheet metals.

The punch and die of the machine will directly contact the plate, so the material of the die is particularly important.

The material of the workpiece also needs to be considered, for the material with rolling chips will wear the die.

After use, the punch and die need to be maintained regularly to avoid rust and corrosion.

After each use, wipe the punches and dies with a clean, lint-free towel and alcohol.

This is done to eliminate fingerprints as the pH of the hands will corrode the die surface.

Then wear gloves to apply anti-corrosion lubricant to the punches and dies.

Finally, put them into the toolbox and place at least one bag of silica gel in it.

If the punch or die is damaged, it needs to be replaced.

Conclusion

Regular maintenance of the press brake is an effective way to prolong the machine's service life.

Maintenance of the press brake includes the hydraulic circuit, hydraulic accessories, tooling system, and electronic accessories.

Additionally, lubrication of mechanical parts, guide rails, back gauges, axes, ball screws, and other parts is necessary, as well as the cleaning of the foundation.

ADH is a professional manufacturer of press brakes, including CNC press brakes, NC press brakes, etc.

We also provide professional after-sales service. If you have any issues with your press brake, you can contact our after-sales team.