I. Introduction to Press Brake Tooling

Definition and primary function

Press brake tooling is a tool used by press brake to form and manufacture sheets.

The tooling comprises punch and die, which cooperate together and used for metal sheet punching, forming, and separating. The mold used for forming has a cavity, and the mold used for separation has a cutting edge.

In essence, press brake tooling refers to a specialized tool used for press brake, which can transform the blanks into components with specific shapes and sizes under the pressure of the press brake.

For beginners, it is essential to know the basic knowledge, such as the interaction between the machine punch and die and metal sheets.

This process involves one metal sheet sliding between the two tools: the top tool (punch) descends onto the bottom tool (die) to bend the parts.

Importance in the metal bending process

Determine the bending form and size accuracy: the shape and size of the tooling can directly determine the bending forms, such as angle, radius of curvature, etc., which is relevant to product quality.

Control the bending process: the tooling can fix the metal sheet on a specific location and control its deformation under pressure to keep the bending consistent.

Improve production efficiency: through fast-changing tooling, the tooling switching of the different products can be finished in milliseconds, largely shortening the switching period.

Prolong the lifespan: the tooling made with abrasive material and dealt with surface treated has several times longer lifespan.

Reduce the production cost: use precise tooling can improve productivity and decrease the waste rate caused by tooling consumption.

Achieve specific requirements: through CNC technology, the tooling can be bent into any form and meet some particular product manufacturing.

II. Press Brake Tooling Components

Top punch and bottom die: they are the key components to determine the bending shape of the workpiece, which are installed on the upper and lower pressure rods to control the deformation of the bending area of the metal plate.

Die shoes: these platforms support and locate the top punch and bottom die. They are connected with the press brake punch to switch the tooling quickly.

Bending assistance tool: to help operators finish the bending tasks quickly and easily, sometimes, some assistant tools may be used, such as angle measuring tools and positioning blocks.

Quick change system: many modern press brakes are equipped with fast-changing systems, allowing operators to quickly replace the top punch and bottom die to adapt to different bending tasks.

Locator pins: they are used to precisely position and fix the workpiece in the die during the bending process. It is essential to locate the locator correctly.

Die protectors: install the die protectors on the rim of the die, which can protect the workpiece's acute angle and prolong the die's lifespan.

Die sockets: connect the die sockets to the punch interface, which benefits the fast installation and removal of the die.

Lubrication systems: distribute the lubrication evenly into the radius of the mold to reduce the workpiece abrasive and burning.

Die pads/blocks: these are used to support dowels and help build toolsets. Rigidity is important.

Spacers: control the bending depth by keeping the distance of the bending surface consistent.

Die drifts: they are used to remove the bending components and can also be used in the setting.

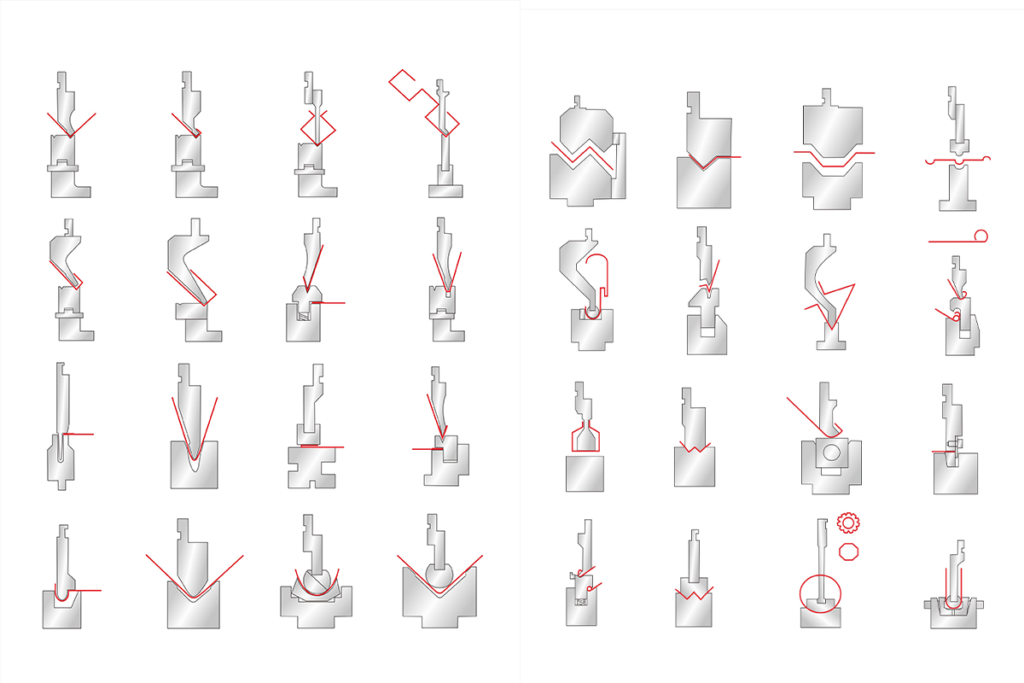

III. Common Dies Used in Press Brake Tooling

Rocker-type die: this type of die, rocker, bends the metal via slides up and down on the metal sheets.

Gooseneck dies: gooseneck die features distinctive shape, which is similar to the gooseneck. They are mainly designed for removing protruding edges or flanges on workpieces, making them the ideal choice for bending profiles with deep boxes or high flanges.

V die: v shaped die is the most common type of die, which features a shaped groove. It is used to create v-shape bending for the workpiece. The width and depth of the v groove determine the final bending angle and radium.

Acute-angle die: these are used to form acute, obtuse, or right-angle bends. The specific design of the die groove can control the bending angle, ensuring the product's final accuracy.

Seaming dies: a seaming die is a specific tool for forming seaming on the sheets and pipes. They are paramount to connecting the two metal sheets, especially in applications such as piping systems or metal containers.

Combination die: combine the shapes and functions of multiple dies into one die, such as bending and grooving.

Hemming dies: transform the flat edges of the workpiece into circular and seaming shapes for finishing.

Bead dies: they are used to create circular and semi-circle protruding edges.

Draw dies: use tubular draw beads to draw and shape the workpiece to form the shell.

Punching die: punch the hole on the workpiece during the bending process.

Stripping dies: they are suitable for applications requiring bend allowance release along curved edges.

Clinching dies: join separate metal parts by punching one through the other during the bend.

U-shaped die: the bending angle ranges from 90°-180°.

IV. Tooling Strength and Material

The efficiency and lifespan of the press brake tooling have an inner connection with the tooling strength and material.

The ingredients and handling of the tooling are paramount because of the tremendous pressure and abrasive during the bending process.

Importance of high-strength and abrasiveness

Press brake tooling withstands the strict pressure during the operation.

High intensity ensures the tools can provide the pressure without deformation and breaking.

Moreover, abrasive-proof is essential owing to its determination of the user lifespan. The abrasive-proof tool can keep its shape and function for a long time, ensure consistent bending results, and reduce the requirements for changing regularly.

Hardened tooling

One of the methods to improve the press brake's rigidness and durability is through hardening tooling.

The specific material is popular due to its initial rigidness and further hardening ability. For example:

Chromium-molybdenum steel: this alloy is known for its toughness and wear resistance, which can achieve a balance between the intensity and durability of press brake, ensuring the tools can handle the heavy-duty bending operation without being prematurely worn.

Yasuki Steel: yasuki steel is a high-grade steel usually used for specialized tools and is famous for its superior rigidness and abrasiveness. Its ingredients can keep its sharp edge, making it an ideal choice for precise and bending tasks.

Thermally refined tooling

Tempering or heat treatment is a process for enhancing the properties of metal tools.

By subjecting a metal to controlled heating and cooling cycles, its molecular structure is changed, improving its properties. For example:

Carbon steel: after heat treatment, carbon steel exhibits increased strength and wear resistance. The heat treatment process refines the grain structure of the steel, making it stronger and more durable. Carbon steel tools are tempered and resistant to chipping and deformation, ensuring longer tool life and consistent bending results.

V. Handling and Installation of Tooling

The operation efficiency of the press brake depends on the tool's quality and also on how the tool is treated and installed.

The correct handling and installation can keep the best performance, reduce wear, and prolong the tool's lifespan.

The following introduces the slight difference in the handling and installation of tooling:

Importance of tooling geometry

The geometry of press brake tooling is designed intricately to achieve bending results.

The shape, angle, and size of each tooling are essential to ensure the accuracy of the bending process. When handle and install these tools:

- Ensure the tooling geometry is consistent with the anticipated bending operation. Using the wrong geometry tooling may cause inaccurate bending results and cause potential damage to the tooling and workpiece.

- Regular checking whether the tooling is wearing or defamation or not. With time passing, the tooling geometry will change simultaneously owing to wearing, which leads to the bending quality.

- Proper storage is crucial. Store tools in a way that preserves their geometry to avoid stacking or placing them in a position where they will be deformed.

Sectionalized tooling and its advantages

Sectionalized tooling refers to a tooling group being divided into many parts or segments.

Sectionalized tooling is not merely long tooling but allows operators to use shorter tool segment combinations to achieve the required length or setting. The advantages are just as follows:

- Flexibility: sectionalized tooling provides stronger versatility, allowing operators to match the segment according to the programs’ specific requirements.

- Easy operation: compared with more extended tools, the shorter tools are more easier to operate, install, and restore.

- Wear reducing: if the specific parts of the tooling are worn or damaged, replace them instead of changing the whole.

- Cost-effectiveness: the operator can invest in a sectionalized group rather than multiple long tools used for different operations, thus reducing the cost in the long term.

- Optimized working procedure: the sectionalized tooling can reset quickly to reduce setting time and improve the rate of productivity.

VI. Importance of Tooling Tolerances

The tooling tolerance is essential in manufacturing because it determines the regular operation of the product, beautiful receptacle measuring range, or other physical properties.

And here are the main reasons for its importance:

Improving part fit and function: the tolerance ensures the parts can cooperate with other components, thus avoiding functional problems and incompatibility.

Strengthening the final product outlook: tolerance is beneficial to realize the product's beauty, such as ensuring the parts leveling without apparent interval.

Considering reasonable tolerance: the tooling tolerance can allow existence while keeping its function.

Interchangeability of parts: the tolerance allows for single components replacement, which is convenient to maintain and repair.

Consistency, accuracy, and precision: the definition of tolerance can better control the product’s consistency, accuracy, and precision.

Lower the cost: the manufacturer can minimize costly manufacturing errors and rework by pre-defining the tolerance.

VII. FAQs

What steel is press brake tooling?

The press brake tooling is usually composed of various steels, such as T8 steel, T10 steel, 42CrMo, and Cr12MoV.

These steels feature high intensity, toughness, and abrasiveness, suitable for the strict application needs of press brakes.

The specific choice for steel depends on factors like the lifespan of the tooling, forming material, and the required level of precision.

Please note that different manufacturers have different preferences when choosing the press brake tooling steel.

How long is the press brake tooling?

Generally speaking, the mold length range of common bending machine models is as follows:

Small machine (working length 1-2 meters): mold length 0.5-1.5 meters

Medium-sized machine (working length 2-4 meters): mold length 1-3 meters

Large machine (working length more than 4 meters): mold length 2-5 meters

Apart from these, the professionally customized large-size molds’ length can live up to 5-10 meters.

The reasonable design of the die structure, the press brake model, and the product's feature can determine the best length for bending tasks.

What are the angles for press brake tooling?

The angle of the press brake tooling is changed according to the actual application and requirements.

The most common types of press brake tooling include v die, u die, and z die, which are used to create different bending shapes.

The angle of the v die ranges from 85 to 90°, and the punch’s angle usually ranges from 85°to 88°.

The angle of the u die ranges from 30 to 85°, and the punch’s angle usually ranges from 85°to 88°.

The angle of z die ranges from 30 to 85°, and the punch’s angle usually ranges from 85°to 88°.

Please note that different manufacturers have their own preferences for the angle of press brake tooling.

VIII. Conclusion

Press brake tooling is essential in press brake fabrication.

Whether for operators, manufacturers, or anyone who participates in metal fabrication, knowing the press brake tooling can significantly improve the accuracy of the bending process, reduce material waste, and generate more benefits.

If you need a press brake machine, you can contact us directly.

If you want to learn more about the machine tool, you can browse our official website for details.