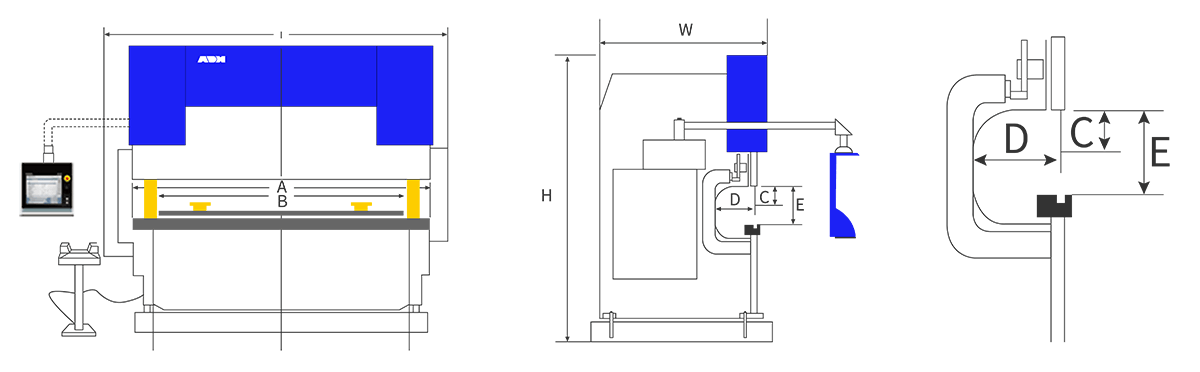

| Model | Bending Force | Bending Length (A) | Aprroaching Speed | Ram Speed | Return Speed | Column Distance (B) | Throat Depth (D) | Stroke (C) | Opening Height (E) | Main Motor | Weight | Dimension |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | KN | mm | mm/s | mm/s | mm/s | mm | mm | mm | mm | KW | Ton | L*W*H mm |

| 50T/1300 | 500 | 1300 | 220 | 13 | 160 | 1120 | 300 | 150 | 460 | 5.5 | 4.5 | 1800*1500*2300 |

| 70T/1600 | 700 | 1600 | 220 | 13 | 160 | 1300 | 300 | 150 | 460 | 5.5 | 5.3 | 2300*1600*2500 |

| 70T/2500 | 700 | 2500 | 220 | 13 | 160 | 2050 | 300 | 150 | 460 | 5.5 | 6 | 3100*1600*2500 |

| 80T/2500 | 800 | 2500 | 220 | 12 | 145 | 2050 | 300 | 150 | 460 | 7.5 | 6.5 | 3100*1600*2600 |

| 110T/2500 | 1100 | 2500 | 220 | 12 | 160 | 2050 | 400 | 200 | 480 | 11 | 8.5 | 3100*1800*2600 |

| 110T/3200 | 1100 | 3200 | 220 | 12 | 160 | 2700 | 400 | 200 | 480 | 11 | 8.5 | 3800*1800*2600 |

| 110T/4000 | 1100 | 4000 | 220 | 12 | 160 | 3100 | 400 | 200 | 480 | 11 | 9.5 | 4600*1800*2600 |

| 110T/4100 | 1100 | 4100 | 220 | 12 | 160 | 3600 | 400 | 200 | 480 | 11 | 10 | 4700*1800*2700 |

| 135T/3200 | 1350 | 3200 | 220 | 10 | 130 | 2700 | 400 | 200 | 480 | 11 | 10 | 3800*1800*2700 |

| 135T/4000 | 1350 | 4000 | 220 | 10 | 130 | 3100 | 400 | 200 | 480 | 11 | 11 | 4600*1800*2700 |

| 135T/4100 | 1350 | 4100 | 220 | 10 | 130 | 3600 | 400 | 200 | 480 | 11 | 11 | 4700*1800*2700 |

| 170T/3200 | 1700 | 3200 | 160 | 10 | 100 | 2700 | 450 | 200 | 480 | 15 | 11.8 | 3800*2000*2800 |

| 170T/4000 | 1700 | 4000 | 160 | 10 | 100 | 3100 | 450 | 200 | 480 | 15 | 13 | 4600*2000*2800 |

| 170T/4100 | 1700 | 4100 | 160 | 10 | 100 | 3600 | 450 | 200 | 480 | 15 | 13.5 | 4700*2000*2800 |

| 220T/3200 | 2200 | 3200 | 160 | 9 | 105 | 2600 | 450 | 200 | 480 | 18.5 | 13 | 3800*2200*2850 |

| 220T/4000 | 2200 | 4000 | 160 | 9 | 105 | 3100 | 450 | 200 | 480 | 18.5 | 15 | 4600*2200*2850 |

| 250T/3200 | 2500 | 3200 | 100 | 8.5 | 100 | 2600 | 450 | 250 | 540 | 22 | 16.5 | 3800*2000*2900 |

| 250T/4000 | 2500 | 4000 | 100 | 8.5 | 100 | 3100 | 450 | 250 | 540 | 22 | 19 | 4600*2100*3100 |

| 250T/5000 | 2500 | 5000 | 100 | 8.5 | 100 | 3800 | 450 | 250 | 540 | 22 | 23 | 5600*2150*3150 |

| 250T/6000 | 2500 | 6000 | 100 | 8.5 | 100 | 4800 | 450 | 250 | 540 | 22 | 25 | 6600*2150*3150 |

| 300T/3200 | 3000 | 3200 | 80 | 8.5 | 110 | 2600 | 500 | 250 | 570 | 22 | 19.5 | 3800*2250*3200 |

| 300T/4000 | 3000 | 4000 | 80 | 8.5 | 110 | 3100 | 500 | 250 | 570 | 22 | 21 | 4600*2500*3400 |

| 300T/5000 | 3000 | 5000 | 80 | 8.5 | 110 | 3800 | 500 | 250 | 570 | 22 | 27.5 | 5600*2500*3400 |

| 300T/6000 | 3000 | 6000 | 80 | 8.5 | 110 | 4800 | 500 | 250 | 570 | 22 | 31 | 6600*2500*3400 |

| 400T/3200 | 4000 | 3200 | 80 | 8 | 80 | 2600 | 500 | 300 | 610 | 30 | 23 | 3800*2700*3500 |

| 400T/4000 | 4000 | 4000 | 80 | 8 | 80 | 3100 | 500 | 300 | 610 | 30 | 30 | 4600*2700*3500 |

| 400T/5000 | 4000 | 5000 | 80 | 8 | 80 | 3800 | 500 | 300 | 610 | 30 | 32 | 5600*2700*3500 |

| 400T/6000 | 4000 | 6000 | 80 | 8 | 80 | 4800 | 500 | 300 | 610 | 30 | 38 | 6600*2700*3500 |

| 500T/4000 | 5000 | 4000 | 80 | 8.5 | 90 | 3100 | 500 | 300 | 610 | 37 | 37 | 4600*2700*3500 |

| 500T/5000 | 5000 | 5000 | 80 | 8.5 | 90 | 3800 | 500 | 300 | 610 | 37 | 42 | 5600*2700*3500 |

| 500T/6000 | 5000 | 6000 | 80 | 8.5 | 90 | 4800 | 500 | 300 | 610 | 37 | 48 | 6600*2700*3600 |

| 600T/4000 | 6000 | 4000 | 80 | 8.5 | 85 | 3100 | 600 | 320 | 650 | 45 | 48 | 4600*3300*3900 |

| 600T/5000 | 6000 | 5000 | 80 | 8.5 | 85 | 3800 | 600 | 320 | 650 | 45 | 52 | 5600*3300*3900 |

| 600T/6000 | 6000 | 6000 | 80 | 8.5 | 85 | 4800 | 600 | 320 | 650 | 45 | 58 | 6600*3300*3900 |

| 600T/7000 | 6000 | 7000 | 80 | 8.5 | 85 | 5600 | 600 | 320 | 650 | 45 | 68 | 7600*3300*3900 |

| 700T/6000 | 7000 | 6000 | 80 | 8.5 | 85 | 4900 | 600 | 320 | 700 | 55 | 78 | 6600*3500*4000 |

| 800T/6000 | 8000 | 6000 | 80 | 8 | 90 | 4600 | 600 | 320 | 800 | 30*2 | 79 | 6600*3500*4000 |

| 800T/7000 | 8000 | 7000 | 80 | 8 | 90 | 5600 | 600 | 320 | 800 | 30*2 | 7600*3500*4200 | |

| 800T/8000 | 8000 | 8000 | 80 | 8 | 90 | 6600 | 600 | 320 | 800 | 30*2 | 8600*3600*4500 | |

| 800T/10000 | 8000 | 10000 | 80 | 8 | 90 | 7800 | 600 | 320 | 800 | 30*2 | 10600*3600*4900 |