Introduction

A press brake is a machine tool used in metal forming to bend and shape metal sheets.

These machines are widely utilized in industries such as construction, automobile, aerospace, and others involved in sheet metal processing and manufacturing.

The workpieces produced by a press brake can have various shapes, ranging from simple to complex parts.

The press brake is equipped with various pressure systems, including mechanical, hydraulic, electric, and pneumatic.

The power device exerts pressure on the ram, causing the upper die to move downwards and press the metal plate into the lower die, thereby completing the bending process.

Through repeated and precise bending operations, the desired workpiece is produced.

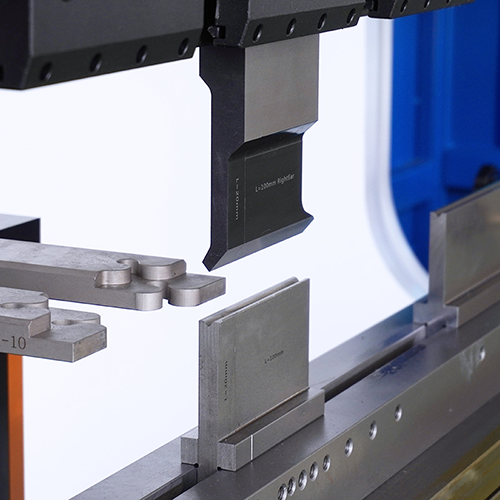

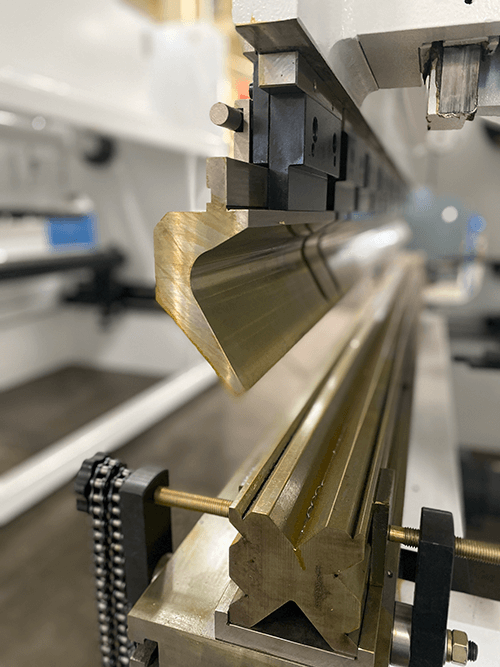

The press brake's die is comprised of two parts: the upper die (punch) and the lower die.

The combination of these two dies, with their different shapes, acts upon the plate to form workpieces of various shapes.

Overview of Press Brake Tools and Accessories

Different Types of Press Brake Tools and Their Functions

The components of a press brake include a conventional die assembly, an upper die (punch), and a V-shaped die.

It is important to choose different press brake dies based on the type of metal sheet being used.

For instance, when working with metal plates that have high tensile strength, the die must also have a matching hardness to prevent damage to the die or incorrect bending of the metal sheet.

The conventional tooling group consists of an upper die and a lower die, which work together to bend the metal sheet.

The punch is usually made of materials with high hardness to effectively extrude or cut the metal plates.

Similarly, the lower die requires a material of equal hardness since the punch will press the metal sheet into it.

The upper die (punch) of the press brake can have special shapes and angles to produce workpieces with specific shapes.

These special punches include standard punches, gooseneck punches, sash punches, arrow punches, acute punches, and others.

Press brake dies are commonly made from hardened steel, such as chromium-molybdenum steel, to prevent punch cracking caused by excessive pressure or plate hardness.

The use of materials with high hardness also helps ensure the durability of the punch.

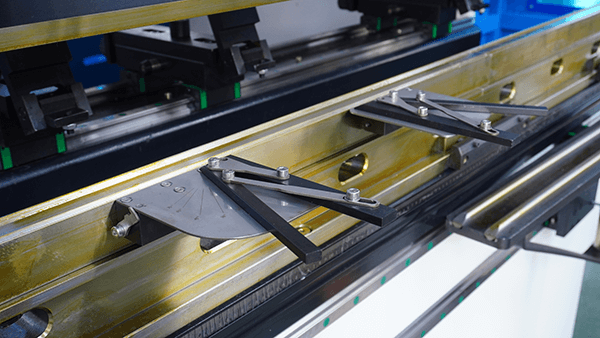

The lower die of a press brake can be classified into four types: the V-shaped die, the U-shaped die, the single die, and the double die.

The V-shaped and U-shaped dies are made of the same material as the punch and are known for their durability and high hardness.

The size of the opening in the V-shaped die affects the choice of bending radius for the workpiece and the method of bending.

The lower die's groove is designed to fit the upper die, allowing the sheet to be securely fixed and molded into the final shape of the workpiece.

Punches and dies are the primary tools used in a press brake.

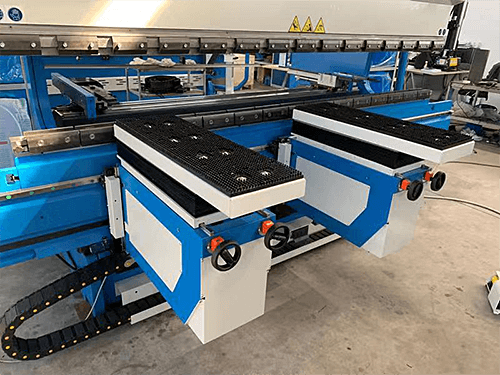

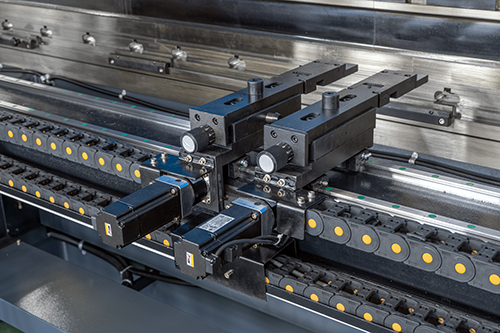

In addition to these, the press brake also has other essential auxiliary tools such as the back gauge, clamping tool, and support rack.

Other components of the press brake work together to ensure accurate bending position, angle, and speed, resulting in improved accuracy and quality of the final workpiece.

Using High-Quality Press Brakes Tools and Accessories

The significance of using high-quality press brake punches dies, and accessories are obvious.

These components can improve the precision of parts by providing precise press brake dies and other accessories.

The punch and die material should be sturdy enough to withstand wear and breakage.

Quality tooling materials can also extend the lifespan of the tool and prevent deformation.

High-quality tooling ensures the quality of the bent workpiece, reducing errors in the final product.

This, in turn, improves press brake production efficiency and reduces production costs.

Dies with a high level of matching and quality are highly effective in sheet bending.

Advanced and high-quality accessories can enhance bending speed, accuracy, and final product quality.

For instance, accurate positioning of the backgauge and each axis can enhance the accuracy of the flange length and size of the workpiece.

Quality hydraulic devices can provide consistent stroke and eliminate bending angles caused by inconsistent speed.

By using high-quality tooling and accessories, the bending quality of the press brake is ensured and the machine's lifespan is extended.

This results in guaranteed product quality, improved production efficiency, and reduced production costs.

Common Press Brake Tools and Accessories

Press Brake Dies and Punches

The press brake die is divided into two parts, the upper die and the lower die, which work together to bend the sheet metal.

The upper die can be further divided into various types such as right angle, acute angle, obtuse angle, gooseneck die, standard die, and others.

The lower die, on the other hand, consists of different types such as the V-shaped die, U-shaped dies, single groove die, and double groove die.

The upper die, powered by the ram, presses the metal sheet into the lower die, shaping it into the desired form.

The die is typically made of high-hardness steel to prevent breakage.

Angle Gauges and Protractors for Measuring Bend Angles

When bending metal plates, the tools used to measure the bending angle are referred to as angle gauges and protractors.

Press brake punches and dies are used to shape the metal sheets into various angles and forms.

To guarantee the precision of the bending angle, angle gauges, and protractors can be employed.

Correct the bending angle and verify its accuracy by using the angle gauges and protractors.

There are various kinds of angle gauges and protractors, typically made of steel for support.

Press Brake Tools Lubrication

The utilization of lubricants can reduce wear and tear caused by long-term use of the press brake dies and components.

The lubricants used for the press brake consist of cutting oil, grease, and wax.

Lubricants can enhance the bending efficiency and prolong the lifespan of the press brake.

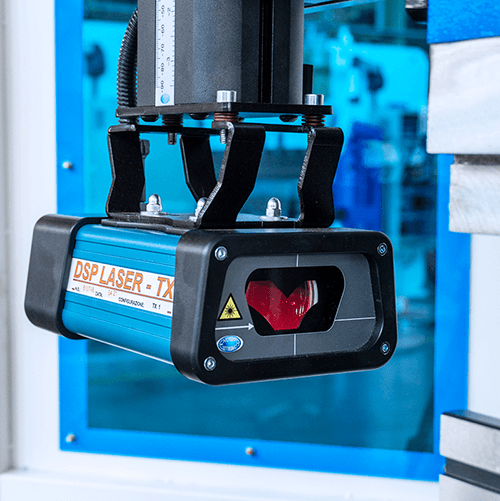

Safety Protection Devices

To protect the operator from any harm during bending, the press brake must be equipped with safety and protective devices.

Such safety protection devices include protective fences, gloves, and other personal protective equipment.

Additionally, there are specialized protective devices installed on the press brake's operating parts.

The press brake's brake caliper is fitted with a guard plate, which acts as a thermal braking component. Contact with this component may result in injury to the operator.

Conclusion

This blog aims to introduce you to the common press brake tools and highlight the importance of using high-quality tools.

The tools used in a press brake machine include press brake punches and dies, a backgauge, a protractor, a hydraulic device, and a protective device, among others.

High-quality press brake tools are an essential component of a top-performing press brake machine.

In the long run, choosing a press brake with a moderate price but high quality can effectively reduce production costs.

The press brakes produced by ADH boast high quality, exceptional performance, and a cost-effective price.

If you require further information about the ADH press brake, our product experts are available to assist you.

FAQs

How Do You Set up A Press Brake Tool?

Before installing press brake tooling, it is important to thoroughly review the drawings.

Familiarize yourself with the characteristics and thickness of the material to be bent, including the flange size, tolerance, bending angle, radius, and other relevant parameters.

Once you have a good understanding of the material, determine the method of bending, whether it be air bending, bottom bending, or coining.

Then, calculate the tonnage required for the bending process, as each method requires a different amount of force.

After that, determine the number of punches and dies that need to be installed. Then, align and install the upper and lower dies.

Place the punch into the fixture and secure it in place. Then, install the bottom die, but do not tighten it too much. Keep it loose.

Lower the punch, fit it into the bottom die, and make sure the upper and lower dies are aligned and close together.

Finally, tighten the screws and clamps to secure the upper and lower dies.