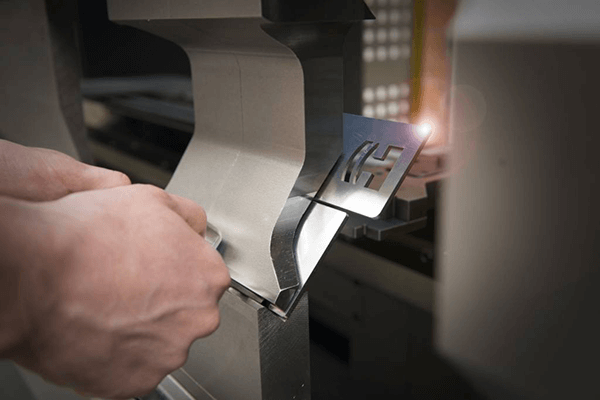

Press brake is widely used in sheet metal manufacturing, and there are several tips and safety guidelines to keep in mind.

For instance, reducing the physical setup time of the press machine, organizing the tool components efficiently, and quickly placing the sheet metal on the workbench.

Additionally, programming the bending procedures, adjusting the workpiece parameters, and accurately positioning the workpiece can improve the efficiency of the press brake operations.

Marking and Storage of Tools

When bending a workpiece with a press brake, having the necessary tools and information readily available can greatly improve work efficiency.

To achieve this, it's important to clearly mark all required information on the machine or tools, such as the number, length, bending angle, radius, height, and maximum load.

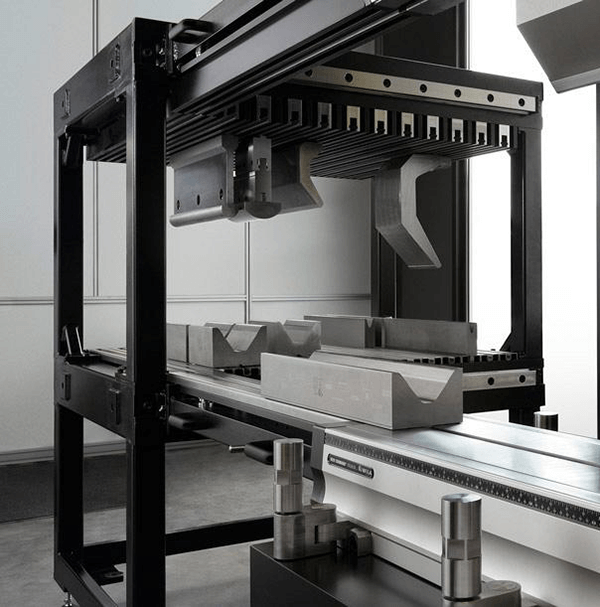

Having organized tool storage is also important.

A customized tool cabinet can be provided to store different sizes and quantities of tool sets, and should be located as close to the press brake as possible for easy access during operation.

This not only helps prevent damage to the tools but also facilitates their replacement and portability to other processing sites using a fork truck.

Remove Die Marks

During bending, dies may leave marks on the workpiece.

This can be remedied by using a press brake dies film, such as a polyurethane non-destructive film, which is commonly used for bending aluminum and stainless steel.

To use the film, simply tape and clamp it to the top of the die before bending.

This will prevent the die from leaving marks on the workpiece. The film is made of polyurethane and can be reused.

Select Appropriate Materials

The properties, tensile strength, and ductility of materials can vary, and these variations will impact the entire bending process.

Plates can be formed into thick or thin plates through hot rolling or cold rolling, which can result in differences in composition and rolling conditions.

The material characteristics can change during bending, causing changes in the bending angle.

The harder the material, the greater the rebound on both sides of the bend.

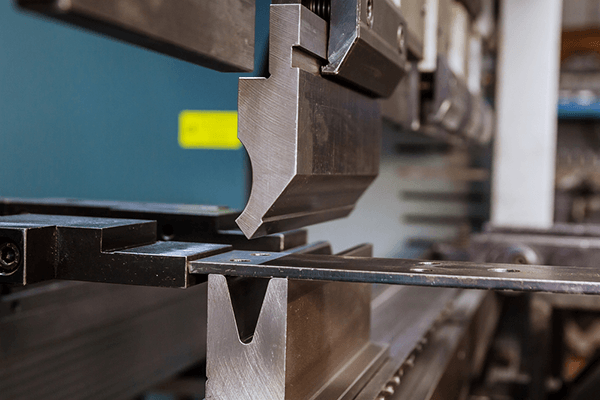

Die and Workpiece Wear

The wear of the die or workpiece after bending is related to the bending radius of the bottom die, which can damage the surface of the V die and result in scratches on the surface of the workpiece.

When selecting a V-shaped die, consider the opening size and bending radius of the V die.

Surface-hardened dies can also be selected to minimize the potential for wear.

Large Tonnage Bending

Before selecting the tooling, it is important to make sure that the bending tonnage falls within the load range of the punch and die.

For example, if the rated range of the die is 20 tons per foot and the workpiece to be bent is 3 feet long, the maximum force exerted by the press brake on the workpiece should not exceed 60 tons.

Exceeding this force could result in damage to the press brake, tooling, and workpiece, and even pose a safety risk to the operator.

Additionally, the clamp system of the press brake also has a limited range of force.

Overloading the clamp system can cause damage to the clamping tools.

When bending thick plates, you can reduce the required tonnage by selecting a V die with a wider opening.

A V die with a hardened positioning rod and shoulder can roll during the bending process, reducing the friction between the workpiece and the die and ultimately requiring less bending force compared to a solid die.

However, this method cannot change the bending radius and flange length of the workpiece.

Applying a large amount of lubricating oil to the shoulder of the V die can also reduce the friction generated during bending, effectively reducing the tonnage required.

While this method can be used occasionally, it's important to clean the press brake after use.

Correct Abnormal Bending Angle

If the bending angle of the workpiece deviates from the programmed angle, it could be due to insufficient tonnage.

Additionally, the bending stroke needs to be maintained for a specific duration in order to form the correct angle.

Another possible cause could be a slow bending speed, which doesn't generate enough pressure on the plate.

The ductility and tensile strength of different materials affect the rebound degree after bending.

The size of the opening in the V-shaped die also influences the final bending result.

To correct an abnormal bending angle, try increasing the tonnage, improving the bending speed, and extending the duration of the bending process.

Additionally, consider using a metal sheet with less rebound and a V-shaped die with a wider opening.

Adjustment of Back Gauge

The accuracy of the back gauge can be improved by adjusting the position of its stop finger.

You can measure any error by using a depth gauge, ensuring that the distance between the stop finger and the center of the lower die is consistent.

Next, check the error on the X-axis. If there is any discrepancy, correct the X-axis reference point value, and then perform the bending process after making the correction.

To align the X-axis with the mold, adjust the timing belt and move the screw on the X-axis forward or backward.

Check for errors at both ends of the X-axis beam, and if none are found, tighten the screws on the timing belt, then perform a bending measurement.

If there is an error on the Y-axis, adjust the Y-axis reference point to correct the error.

Fix the slider below the bending transition point, and after adjusting the parameters of the Y1 and Y2 axes, perform a bending measurement to confirm that there are no errors.

Conclusion

In this article, we have discussed some important considerations and tips for using a press brake.

The use of a press brake requires a broad understanding of the machine and a wealth of experience.

At ADH, we have extensive experience in the field of bending machine manufacturing.

If you need further information, feel free to reach out to us for a discussion.

We are a professional sheet metal machine manufacturer and service provider, offering a range of machines, including CNC press brake, fiber laser cutting machine, shearing machine, and slotting machine.

If you have any ideas or requirements for a bending machine, our team members are here to help.

FAQs

What is the compensation of the bending machine?

The press brake can experience deflection under excessive load, particularly at the center position of the ram and the worktable, causing the angle of the bent workpiece at the center and the angle at both ends to become inconsistent.

To compensate for this deflection, the press brake must be equipped with a crowning device that can generate an opposing force, counteracting the deflection of the ram and the base.

How to tighten the timing belt?

To tighten the timing belt, follow these steps:

- Stop the press brake and open the machine housing.

- Loosen the screws that secure the x-axis motor connecting plate.

- Adjust the position of the tensioner and tighten the screws.

- Reinstall the machine housing.

How to change the filter of the press brake?

- Turn off the power supply to both the machine oil pump motor and the press brake.

- Open the machine housing and remove the filter.

- Replace the filter with a new one and install the machine housing.

- Start the power supply to the machine, turn on the pump motor, and allow the hydraulic oil to filter for a period of time.

- Finally, operate the machine normally.